ibr sheet making machine company

Innovations in the Production of IBR Sheet Making Machines

In the ever-evolving landscape of the manufacturing industry, IBR (Inverted Box Rib) sheet making machines have emerged as a crucial component in the construction and building sector. As the demand for high-quality roofing materials grows, innovative companies are paving the way for enhanced production techniques and machinery that meet these needs. This article explores the significance of IBR sheet making machines, the technology behind them, and the advancements shaping their future.

IBR sheets have become increasingly popular due to their unique ribbed design, which provides superior strength and durability. These sheets are lightweight, easy to transport, and versatile, making them ideal for residential, commercial, and industrial applications. They are resistant to harsh weather conditions and are available in various colors and finishes, providing aesthetic and functional benefits. As a result, the demand for IBR sheets has skyrocketed, creating a pressing need for efficient manufacturing processes.

Innovations in the Production of IBR Sheet Making Machines

One of the most significant trends in the manufacturing of IBR sheet making machines is the integration of automation and smart technology. Modern machines are equipped with computer numeric control (CNC) systems, allowing for precise adjustments and programming. This automation not only enhances production speed but also minimizes waste, making the manufacturing process more environmentally friendly. Furthermore, remote monitoring capabilities enable manufacturers to track performance metrics, maintenance needs, and production output in real-time, ensuring that the machines operate at peak efficiency.

ibr sheet making machine company

Another emerging trend is the focus on sustainability in the production of IBR sheets and machines. Many companies are exploring the use of eco-friendly materials and energy-efficient technologies to reduce their carbon footprint. This shift towards sustainability is being driven by increasing regulatory pressures and consumer demand for greener products. As a result, manufacturers are investing in research and development to create machines that utilize recyclable materials and consume less energy during production.

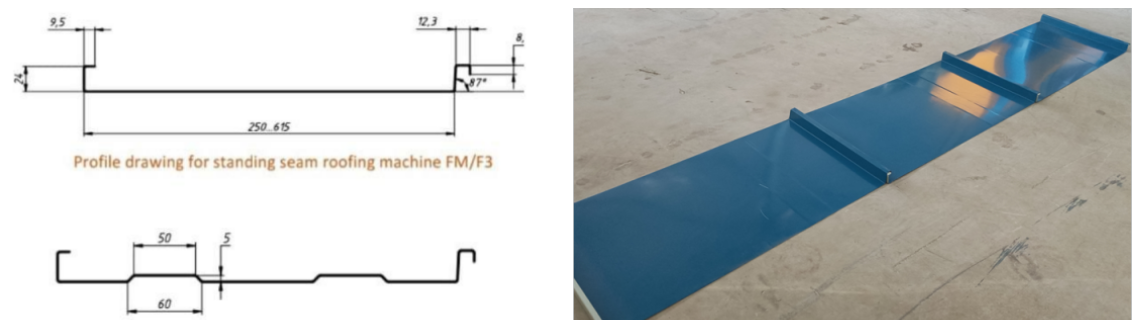

In addition to sustainability, there is a growing emphasis on customization in the IBR sheet market. Manufacturers are recognizing the importance of offering bespoke solutions to meet specific customer requirements. Advanced IBR sheet making machines can be configured to produce various sheet profiles, thicknesses, and finishes, allowing customers to tailor their products to their needs. This flexibility not only enhances customer satisfaction but also opens new avenues for businesses to differentiate themselves in a competitive market.

As the construction industry continues to expand, the future of IBR sheet making machines looks promising. With advancements in technology, sustainability practices, and customization options, manufacturers are better equipped to meet the evolving demands of the market. Companies investing in state-of-the-art machinery will likely gain a competitive edge, delivering high-quality products that align with industry trends.

In conclusion, IBR sheet making machines are vital in the manufacturing of roofing materials in today's construction environment. As the demand for IBR sheets grows, innovations in machine technology, automation, sustainability, and customization play a significant role in shaping the future of this industry. Companies that embrace these advancements will not only enhance their production capabilities but also contribute to a more sustainable and efficient construction sector. The evolution of IBR sheet making machines signifies an exciting era for manufacturers dedicated to meeting the needs of a dynamic market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025