ibr roll forming machine south africa

The Rise of IBR Roll Forming Machines in South Africa

In recent years, South Africa has witnessed significant growth in various manufacturing sectors, particularly in the area of metal fabrication. At the heart of this transformation is the Increasing use of innovative machinery, such as the IBR roll forming machine. These machines have emerged as indispensable tools for the production of IBR (Inverted Box Rib) roofing sheets, which are widely used in the construction industry across the nation.

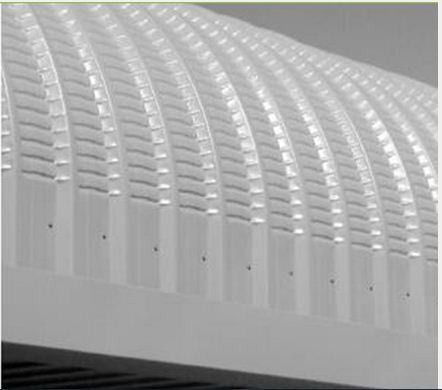

IBR roofing sheets are renowned for their strength, durability, and aesthetic appeal. They are commonly used in industrial and agricultural buildings, commercial properties, and residential structures alike. The unique profile of IBR sheets allows for greater cover width and improved load-carrying capacity, making them a preferred choice among architects and builders. Consequently, the demand for high-quality IBR sheets has surged, prompting manufacturers to seek advanced roll forming technology to meet production needs.

The Rise of IBR Roll Forming Machines in South Africa

In South Africa, several local manufacturers and suppliers of IBR roll forming machines have emerged, catering to the growing demand in the construction and roofing sectors. These companies offer a range of machines, from entry-level models for small businesses to advanced systems equipped with the latest technology for larger operations. The availability of various options has empowered manufacturers to select machines that best fit their production scale and budget, thus fostering local entrepreneurship.

ibr roll forming machine south africa

Moreover, investing in IBR roll forming machines has substantial benefits for South African manufacturers. The machines not only enhance production capacity but also improve the quality of the final products. High-quality IBR sheets produced using advanced roll forming techniques are more resistant to weather elements, ensuring longevity and reduced maintenance costs for end-users. This quality assurance leads to customer satisfaction and can significantly boost a company’s reputation in a competitive market.

Another notable aspect is that IBR roll forming machines are customizable to a degree, allowing manufacturers to produce specialized profiles or tailored dimensions per client specifications. This flexibility enables businesses to tap into niche markets and respond promptly to unique architectural designs and client demands. As a result, many companies have successfully differentiated themselves from competitors, establishing a strong foothold in the metal fabrication industry.

The environmental aspect of manufacturing using IBR roll forming machines is also commendable. These machines can effectively utilize metal sheets with minimal waste, thereby promoting sustainable practices in the industry. With the rising emphasis on sustainability and green building practices, the adoption of efficient and environmentally friendly manufacturing processes aligns well with global trends.

Despite the promising growth of IBR roll forming machines in South Africa, challenges remain. The industry occasionally faces fluctuations in raw material prices, which can affect production costs. Additionally, the need for skilled operators who can effectively manage and maintain these machines is paramount. Therefore, continued investment in training and development is essential for ensuring that the workforce is equipped with the requisite skills.

In conclusion, the rise of IBR roll forming machines in South Africa represents a significant leap forward for the construction and metal fabrication industries. As the demand for high-quality IBR sheets continues to grow, these machines play a critical role in meeting production needs and enhancing the overall quality of roofing solutions. With local manufacturers investing in advanced technology and training, the future of IBR production in South Africa looks promising, heralding a new era of innovation and efficiency in the sector.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025