ibr roll forming machine for sale companies

The Significance of IBR Roll Forming Machines in the Manufacturing Industry

In the bustling world of manufacturing, efficiency, precision, and quality are paramount. One of the most vital pieces of equipment that epitomizes these values is the IBR (Inverted Box Rib) roll forming machine. This advanced machinery is essential for producing metal sheets with specific profile shapes used in various construction applications, particularly in the roofing and cladding industry.

Understanding IBR Roll Forming Machines

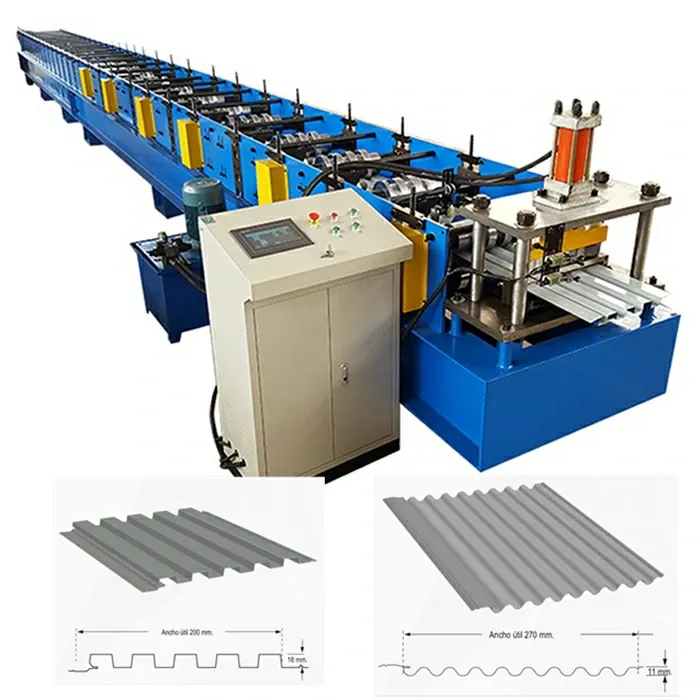

An IBR roll forming machine is designed to create metal sheets with a distinctive ribbed profile. The 'IBR' refers to the profile of sheets that feature inverted box ribs, which enhance their structural integrity and aesthetic appeal. The primary advantage of using this type of machine is its ability to produce high volumes of consistently uniform products with minimal wastage.

The roll forming process involves feeding metal strips through a series of rollers that gradually shape the material into the desired IBR profile

. The precision engineering of these machines ensures that every piece produced meets strict specifications, making them indispensable in sectors where quality cannot be compromised.Market Demand and Applications

The demand for IBR roll forming machines has surged in recent years, driven by the global construction boom. With an increasing number of infrastructure projects, the need for durable roofing and cladding solutions has never been greater. IBR sheets are preferred for their strength, lightweight nature, and ease of installation. They are widely used in industrial buildings, warehouses, and agricultural structures, making them crucial in sectors ranging from construction to manufacturing.

ibr roll forming machine for sale companies

Businesses seeking to invest in IBR roll forming machines must consider several factors, including production capacity, machine quality, and the manufacturer’s reputation. Many companies now offer these machines for sale, providing various options tailored to different operational needs.

Benefits of Choosing IBR Roll Forming Machines

Investing in IBR roll forming machines offers several benefits. Firstly, these machines operate efficiently, significantly reducing labor costs and time requirements for producing metal sheets. Secondly, with advanced technology, many modern roll forming machines come equipped with automation features that enhance production speed and accuracy. This not only boosts productivity but also minimizes the likelihood of human error.

Moreover, the durability of IBR sheets means they require less maintenance and have a longer lifespan compared to traditional roofing materials. This longevity translates to cost savings for businesses and contractors, making IBR roll forming an economically viable option.

Conclusion

In conclusion, IBR roll forming machines play a pivotal role in modern manufacturing, particularly in the construction industry. Their ability to produce high-quality, durable roofing and cladding materials efficiently meets the increasing demand for infrastructure. As companies increasingly recognize the advantages of investing in such machines, the market for IBR roll forming machines continues to grow. Whether for construction firms or manufacturers, investing in this technology represents a significant step towards improved productivity and profitability in today’s competitive landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025