ibr roll forming machine

Exploring the Innovations of IBR Roll Forming Machines

In the realm of modern manufacturing, the IBR (Inverted Box Rib) roll forming machine has emerged as a vital instrument for producing high-quality metal sheets and panels, particularly for roofing and wall applications. This technology proves exceptionally beneficial for construction, agriculture, and industrial sectors, where durability and functionality are paramount. The IBR profile, characterized by its distinctive ribbed design, not only enhances structural integrity but also contributes to aesthetic values, making it a popular choice among builders and architects alike.

Understanding the IBR Roll Forming Process

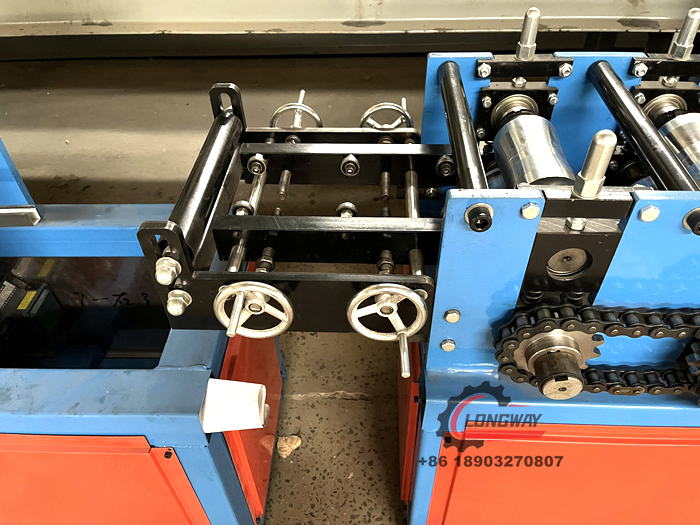

The IBR roll forming process involves a series of continuous bending operations, where a flat metal strip is gradually transformed into a specific cross-sectional profile. Typically made from galvanized steel or aluminum, the material is fed into the machine and driven through multiple rollers that shape it into the desired form. The IBR profile, with its shallow ribs, provides increased strength while maintaining a lightweight structure, which is crucial for efficient installation and transportation.

One of the key advantages of using an IBR roll forming machine is the ability to produce long lengths of metal sheets without joints or seams. This seamless production reduces the chances of leaks in roofing applications, thus enhancing the overall longevity of the building. Furthermore, the uniformity of the product ensures that the finished panels fit together snugly, thereby facilitating easier installation.

Technical Features and Innovations

Exploring the Innovations of IBR Roll Forming Machines

Additionally, many machines come with integrated systems for quality control. These systems monitor the thickness, width, and curvature of the formed sheets in real-time, ensuring that the final products adhere to strict specifications. This level of precision is crucial in industries where structural integrity is non-negotiable.

ibr roll forming machine

Applications of IBR Profiles

The applications of IBR profiles are expansive. In the construction sector, IBR sheets are commonly used for roofing and cladding because of their lightweight nature and resistance to harsh weather conditions. Their ribbed design aids in water drainage, reducing the likelihood of water accumulation and subsequent damage.

Furthermore, these panels are also employed in industrial settings for partitioning and enclosing spaces. Their durability makes them suitable for agricultural buildings, warehouses, and commercial structures, where they serve not only functional purposes but also contribute to energy efficiency.

Economic Benefits

Investing in an IBR roll forming machine can yield substantial economic benefits for manufacturers. The lower material waste, due to precise cutting and shaping techniques, translates to cost savings. Additionally, the ability to produce high volumes in shorter time frames enhances profitability. Companies can meet the rising demand for quality metal products without compromising on speed or standards.

Conclusion

The IBR roll forming machine represents a significant advancement in the manufacturing of metal profiles. By combining innovation and efficiency, it provides a reliable solution for creating durable and aesthetically pleasing building materials. As the construction and industrial sectors continue to evolve, the reliance on such modern machinery will undoubtedly grow. Companies that adopt these technologies are likely to thrive, benefitting from reduced costs, increased production capacity, and enhanced product quality. In conclusion, the IBR roll forming machine not only meets the current industry needs but also paves the way for future developments in metal fabrication, making it an invaluable asset in the manufacturing landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025