IBR roof sheeting machine available for purchase with high efficiency and durability

The Rise of IBR Roof Sheeting Machines A Key Investment for Construction

In recent years, the construction industry has seen significant advancements, particularly in roofing technology. One of the standout innovations has been the introduction of IBR (Inverted Box Rib) roof sheeting machines. These machines have transformed the way roofing materials are produced, offering efficiency, durability, and cost-effectiveness. This article explores the unique features of IBR roof sheeting machines and why they are a sound investment for construction businesses.

Understanding IBR Roof Sheeting

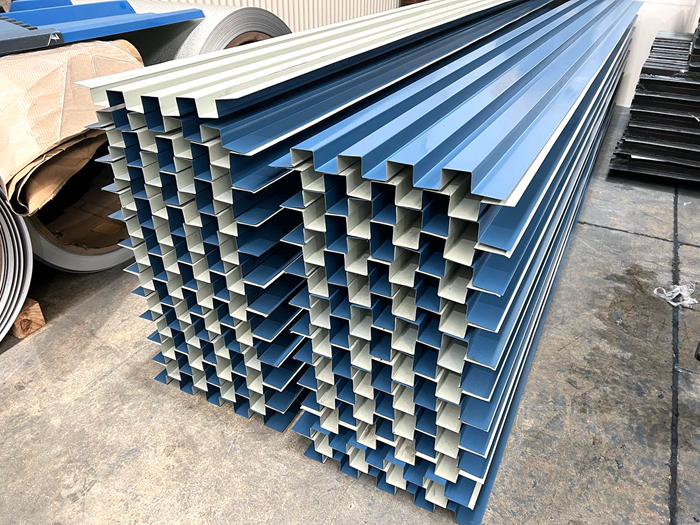

Before delving into the machines themselves, it’s important to understand what IBR roofing involves. IBR sheets are characterized by their distinct ribbed design, which not only enhances aesthetic appeal but also provides superior structural integrity. These sheets are widely used in commercial and industrial roofing applications due to their ability to withstand varying weather conditions and their adaptability to different architectural designs.

Features of IBR Roof Sheeting Machines

IBR roof sheeting machines are designed to manufacture IBR sheets efficiently. They come equipped with several advanced features that streamline the production process. Firstly, these machines offer high-speed operation, capable of producing large volumes of sheets in a shorter time. This is a crucial factor for businesses aiming to meet large-scale project demands.

Secondly, modern IBR machines are designed with precision engineering, ensuring consistent thickness and profile for each sheet. This uniformity is vital for construction projects, where even minor discrepancies can lead to weaknesses in roofing systems. Moreover, advanced technology allows these machines to be easily adjusted to produce sheets of varying lengths, accommodating diverse customer needs.

Additionally, most IBR roof sheeting machines come with user-friendly interfaces and automated controls, reducing the need for extensive training and minimizing human error. This not only enhances productivity but also lowers the overall operational costs, making it a lucrative investment for construction firms.

ibr roof sheeting machine for sale

Economic Advantages

Investing in an IBR roof sheeting machine offers significant economic benefits. For starters, the ability to produce roofing sheets in-house reduces reliance on external suppliers. This not only cuts down on procurement costs but also allows for greater control over the quality and availability of materials. Companies can respond quickly to market demands without the delays typically associated with ordering from third-party manufacturers.

Furthermore, the durability of IBR sheets means that they require less frequent replacement, ultimately saving costs on repairs and maintenance over time. The initial investment in an IBR roof sheeting machine can yield substantial returns as businesses capitalize on these savings along with potential new revenue streams from offering roofing services.

Sustainability and Environmental Impact

In today’s environmentally conscious market, sustainability has become a critical consideration for construction businesses. IBR roof sheeting machines can contribute to this goal by allowing for the recycling of materials. Many manufacturers incorporate recycled steel into their production processes, which not only reduces waste but also decreases the overall carbon footprint associated with roofing projects.

Moreover, the energy-efficient designs of modern machines help minimize power consumption during production, further enhancing their ecological viability.

Conclusion

In summary, IBR roof sheeting machines represent a transformative investment for construction businesses looking to enhance their productivity and adaptability in the market. With their advanced features, economic benefits, and positive environmental impact, these machines are paving the way for a more efficient and sustainable future in roofing solutions. As the demand for high-quality roofing continues to rise, companies that embrace this technology will undoubtedly gain a competitive edge in the industry. For those considering entering the roofing market or expanding their current operations, investing in an IBR roof sheeting machine could be one of the most strategic decisions they make.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025