High-Quality IBR Roof Sheet Making Machines Best Price & OEM

- Overview of IBR roof sheet manufacturing technology

- Technical specifications and production advantages

- Comparative analysis of leading manufacturers

- Price determinants and factory selection criteria

- Customization capabilities for specific applications

- Global implementation case studies

- Future trends in IBR machinery development

(ibr roof sheet making machine)

Understanding IBR Roof Sheet Making Machine Fundamentals

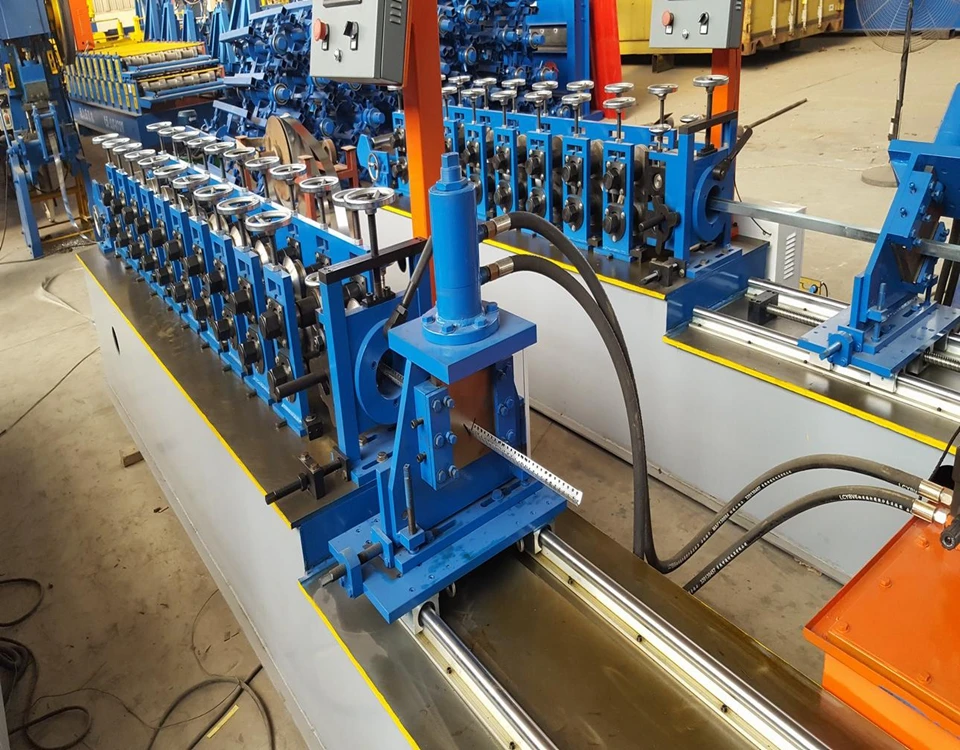

IBR (Inverted Box Rib) roof sheet manufacturing represents a significant advancement in construction material production. These specialized machines transform raw steel coils into high-strength roofing profiles through sequential roll forming operations. Unlike standard roofing systems, IBR profiles feature interlocking side joints that provide superior weather resistance and structural integrity, resulting in 40% faster installation times compared to conventional roofing.

The operational principle involves precision engineering where coil material passes through a series of forming stations that progressively shape the metal into the characteristic inverted box design. Modern IBR machines incorporate intelligent control systems capable of achieving dimensional tolerances within ±0.5mm, ensuring perfect interlock fit for watertight roofing. Production capabilities range from entry-level machines producing 5-7 meters/minute to industrial systems achieving outputs exceeding 25 meters/minute. Material utilization efficiency reaches 95% in optimized systems, significantly reducing construction waste compared to traditional roofing methods.

Technical Specifications and Production Capabilities

Advanced servo-electrical control systems distinguish premium IBR machinery, offering multiple technical advantages. These systems maintain consistent material tension through fully automated servo-driven decoilers with tension capacities up to 10 tons. The hydraulic cutting modules achieve dimensional accuracy within ±0.3mm at cycle speeds of 20-25 cuts/minute, maximizing material utilization. Dual-platen hydraulic systems generating 150 tons of cutting force enable continuous high-speed production without compromising profile consistency.

Modern configurations incorporate integrated quality control mechanisms including laser measurement systems that perform real-time dimensional verification every 3 seconds. Such precision ensures proper water channel formation and interlocking edge geometry critical for leak-proof performance. Production flexibility ranges from 0.4mm-1.2mm thickness capability and material widths spanning 700-1300mm, accommodating diverse architectural requirements while maintaining production efficiency.

Manufacturer Comparison: Capabilities and Specifications

| Manufacturer | Production Speed | Material Thickness | Automation Level | Maintenance Interval | Energy Consumption |

|---|---|---|---|---|---|

| GlobalRoll 5000 | 22-27 m/min | 0.4-1.0 mm | Fully Automated | 750 hours | 35 kWh |

| FormTech ProLine | 18-24 m/min | 0.45-1.2 mm | Semi-Automated | 500 hours | 42 kWh |

| PrecisionFab HD | 15-20 m/min | 0.5-1.0 mm | Basic Automation | 400 hours | 48 kWh |

| EuroSteel Master | 25-30 m/min | 0.4-1.1 mm | Fully Automated | 900 hours | 32 kWh |

Pricing Structures and Manufacturer Selection

The investment for IBR roof sheet machinery spans $85,000 for semi-automated systems to $350,000+ for fully automated production lines with robotic material handling. Beyond the base equipment cost, configuration impacts pricing substantially: adding automatic tool changing capability increases investment by approximately 18%, while integrated quality inspection systems add another 12-15%. Operational expense analysis reveals that automation levels significantly impact long-term costs, with fully automated systems requiring 30% less labor while maintaining up to 95% operational uptime.

Leading manufacturers with integrated R&D facilities typically provide superior technical support with response times under 12 hours for critical issues. When evaluating suppliers, verify third-party certifications including ISO 9001:2015, CE compliance for European operations, and locally required industrial safety certifications. Equipment warranties range from 12 months for mechanical components to 36 months on hydraulic systems and PLC controls. Opt for manufacturers providing comprehensive spare parts packages covering 85% of common replacement items to minimize production downtime.

Customized Production Solutions

Leading manufacturers accommodate extensive customization beyond standard IBR profiles to meet specific project requirements. Engineering teams typically modify machines within four technical dimensions: roll station configuration adjustments for alternative rib spacing and heights, cutting system reprogramming for precise panel lengths from 1m to 18m, software modifications for specialized coatings including PVDF and SMP paints, and structural reinforcement for handling specialty alloys. Custom roll tooling configurations for unique profile geometries require approximately 30-45 days manufacturing time plus rigorous load simulation testing before deployment.

Material flexibility remains crucial in custom implementations. Modified forming stations accommodate high-tensile steels up to 550MPa yield strength and coated materials including Galvalume, aluminum-zinc alloys, and pre-painted sheets up to 120 GSM coating mass. Climate adaptations include tropicalized electrical systems maintaining operational stability at 90% humidity and 45°C ambient temperatures, plus Arctic packages ensuring functionality at -40°C. Energy optimization options incorporate regenerative drive technology reducing consumption by 15-18% during variable load operations.

Global Implementation Case Studies

The Dubai Infrastructure Project implemented an advanced IBR production facility achieving remarkable results: monthly output reached 650,000 sq. meters during phase one construction, supplying premium 0.55mm Galvalume panels with customized rib configurations. Throughput efficiency reached 93% operational utilization with minimal waste, attributed to the automatic nesting software that maximized material usage per coil. These efficiency gains translated to $2.7 million in material cost savings during the initial 14-month construction window.

In Northern European applications, specialized machinery produced snow-load optimized profiles at a Swedish manufacturing plant. These systems incorporated modified roll stations forming structural reinforcements that increased load-bearing capacity by 40% compared to standard profiles to withstand 210kg/m² snow accumulations. Production efficiency remained consistent at 85% despite the thicker gauge steel (0.8-1.0mm) processed, with the equipment configured for continuous operation at ambient temperatures down to -35°C without hydraulic performance degradation.

The Future Trajectory for IBR Roof Sheet Machinery

The IBR roof sheet making machine industry continues evolving toward greater automation and energy efficiency as construction demands increase. Manufacturers are implementing IoT-enabled predictive maintenance protocols that reduce unplanned downtime by 65% through real-time component health monitoring. Research centers currently test nano-coated forming rollers that extend tooling life by 3x while improving surface finish quality on production materials.

Advanced IBR roof sheet making machine production systems increasingly incorporate AI-driven optical inspection that detects profile imperfections with 99.7% accuracy compared to human operators. Forward-thinking factories have begun linking multiple IBR roof sheet making machine systems to centralized cloud platforms for synchronized production planning. These advancements allow manufacturers to enhance capabilities while maintaining competitive price positions as global infrastructure requirements continue growing across all market sectors.

(ibr roof sheet making machine)

FAQS on ibr roof sheet making machine

Here are 5 FAQ pairs in HTML rich text format focused on the requested :Q: What is an IBR roof sheet making machine?

A: An IBR roof sheet making machine manufactures IBR (Inverted Box Rib) profile metal sheets used for roofing and cladding. It forms sheets through precise cold-rolling of steel coils into specific trapezoidal designs. These automated systems handle uncoiling, forming, and cutting in one continuous line.

Q: Which companies manufacture IBR roof sheet making machines?

A: Leading companies include techsyn-industries.com, rollformindia.com, and sinosheetmachine.com. These manufacturers specialize in customized metal roll forming systems. They provide global services with R&D-focused production facilities.

Q: How much does an IBR machine cost from manufacturers?

A: Manufacturer prices range from $45,000 for basic models to over $200,000 for fully automated lines. Key cost factors include production speed (8-45m/min), material thickness capacity (0.2-0.8mm), and automation level. Direct manufacturer quotes include installation training.

Q: Do factories offer lower prices for IBR sheet machines?

A: Large factories often provide 10-20% lower prices due to bulk production scales. Costs decrease further for standardized configurations versus custom solutions. Note that factory-direct machines may require separate technical support contracts versus manufacturer packages.

Q: How to choose between manufacturers and factories for purchase?

A: Prioritize manufacturers for customized solutions and comprehensive after-sales support. Choose factories for budget-focused, high-volume standardized equipment purchases. Always verify production certifications (ISO 9001) and request material test reports before ordering.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025