Hydraulic-Driven Automatic Roll Forming Equipment for Efficient Metal Fabrication Solutions

The Hydraulic Automatic Roll Forming Machine Revolutionizing Manufacturing

The evolution of manufacturing technology has seen remarkable advancements over the years, and one of the most significant innovations in this field is the hydraulic automatic roll forming machine. This machine has dramatically transformed the way engineers and manufacturers produce metal components, making processes more efficient, precise, and versatile.

What is a Hydraulic Automatic Roll Forming Machine?

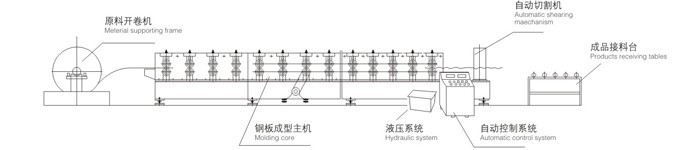

A hydraulic automatic roll forming machine is a type of machinery used to shape metal sheets into specific profiles by passing the material through a series of rollers. Utilizing hydraulic power, these machines can exert significant force to mold materials into desired shapes with exceptional accuracy. The automatic aspect of the machine allows for consistent and continuous operation without the need for significant manual intervention, which enhances production speed and reduces labor costs.

Key Features and Benefits

1. Precision and Consistency One of the standout features of hydraulic automatic roll forming machines is their ability to deliver precise dimensions consistently. The advanced control systems employed in these machines allow manufacturers to achieve tight tolerances, which is crucial in industries where even minor deviations can lead to significant problems.

2. Versatility These machines can produce a wide variety of profiles, such as C-sections, Z-sections, channels, and more. This versatility makes them ideal for various applications, including construction, automotive, and appliance manufacturing. The ability to easily change dies and settings enables manufacturers to quickly adapt to new projects or changes in demand.

hydraulic automatic roll forming machine

3. Efficiency The hydraulic system allows for faster operation and higher output rates compared to traditional mechanical systems. Additionally, the automation capabilities reduce the need for constant supervision, allowing staff to focus on other critical tasks while the machine runs.

4. Durability Hydraulic automatic roll forming machines are built to withstand the rigors of continuous operation. Their robust construction and high-quality components ensure a long service life, making them a worthwhile investment for manufacturers.

5. Reduced Waste Since these machines employ precise cutting and forming techniques, they help reduce material waste. This is especially important in today’s environmentally-conscious manufacturing landscape, where reducing waste can also lead to cost savings.

Applications Across Industries

The hydraulic automatic roll forming machine serves a multitude of industries. In construction, it is used to produce roof and wall panels, purlins, and studs. In the automotive industry, it is employed to create structural components and supports. Additionally, manufacturers of appliances utilize these machines to form parts for refrigerators, ovens, and other household products.

Conclusion

The hydraulic automatic roll forming machine represents a significant leap forward in manufacturing technology. By offering precision, efficiency, and versatility, these machines enable manufacturers to streamline their processes and improve product quality. As industries continue to evolve and demand more sophisticated solutions, the role of hydraulic automatic roll forming machines will undoubtedly grow, solidifying their position as a cornerstone of modern manufacturing. Investing in this technology not only enhances production capabilities but also sets the stage for innovation and growth in a competitive marketplace.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025