Jan . 20, 2025 04:34

Back to list

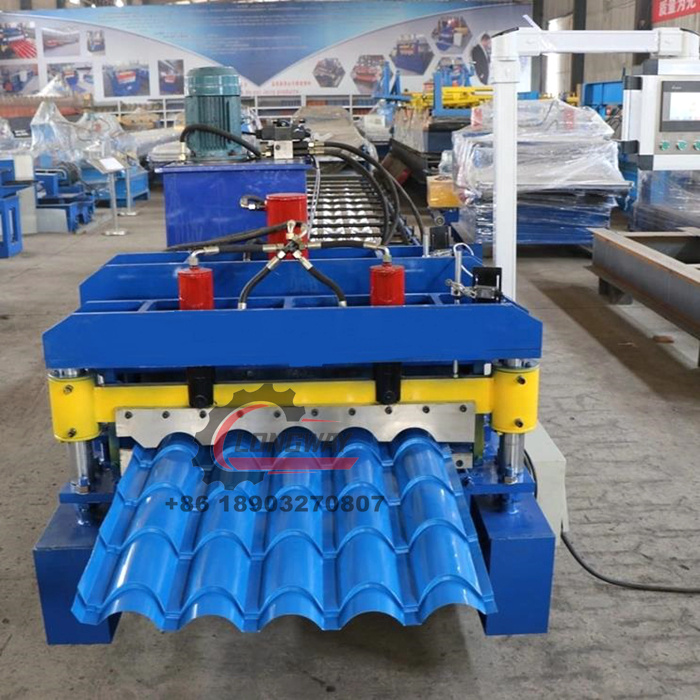

Maquina para PANEL TINGLADO , TINGLADO panel forming machine

Revolutionizing the infrastructure sector, the highway guardrail roll forming machine stands as a testament to manufacturing innovation and engineering prowess. This indispensable tool has become an integral component in producing safety barriers that line highways globally, ensuring the safety of millions of travelers every day. With its unique capabilities, the machine transforms raw materials into robust guardrails, combining precision engineering with automated efficiency.

Trust in the highway guardrail roll forming machines stems from the rigorous testing and quality assurance processes they undergo before deployment. Manufacturers subject these machines to extensive operational checks and stress testing, ensuring they deliver consistently under various conditions. This reliability is critical, especially considering the consequential nature of guardrail performance in real-world highway scenarios. Operators of these machines, experts trained in both the technical and safety aspects of production, play a vital role in maintaining the machines’ optimal performance. Their hands-on experience supports their authoritative stance in advising on the best practices for machine maintenance and operation, further reinforcing the machine's trustworthiness. Furthermore, the evolving nature of technology ensures that these machines are continually updated with the latest advancements. Integration with smart manufacturing techniques, such as IoT capabilities and machine learning algorithms, allows for real-time monitoring and predictive maintenance. This modern approach not only minimizes downtime but also enhances the overall lifecycle and utility of the machines. In conclusion, the highway guardrail roll forming machine is an exemplar of the seamless blend between sophisticated engineering and practical manufacturing solutions. Its contribution to road safety cannot be overstated as it continues to serve as an essential element in producing high-quality guardrails that shield road users from potential hazards. With a foundation built on experience, expertise, authoritativeness, and trustworthiness, these machines embody the gold standard of modern industrial machinery, supporting infrastructure developments that pave the way for safer, more secure transportation networks worldwide.

Trust in the highway guardrail roll forming machines stems from the rigorous testing and quality assurance processes they undergo before deployment. Manufacturers subject these machines to extensive operational checks and stress testing, ensuring they deliver consistently under various conditions. This reliability is critical, especially considering the consequential nature of guardrail performance in real-world highway scenarios. Operators of these machines, experts trained in both the technical and safety aspects of production, play a vital role in maintaining the machines’ optimal performance. Their hands-on experience supports their authoritative stance in advising on the best practices for machine maintenance and operation, further reinforcing the machine's trustworthiness. Furthermore, the evolving nature of technology ensures that these machines are continually updated with the latest advancements. Integration with smart manufacturing techniques, such as IoT capabilities and machine learning algorithms, allows for real-time monitoring and predictive maintenance. This modern approach not only minimizes downtime but also enhances the overall lifecycle and utility of the machines. In conclusion, the highway guardrail roll forming machine is an exemplar of the seamless blend between sophisticated engineering and practical manufacturing solutions. Its contribution to road safety cannot be overstated as it continues to serve as an essential element in producing high-quality guardrails that shield road users from potential hazards. With a foundation built on experience, expertise, authoritativeness, and trustworthiness, these machines embody the gold standard of modern industrial machinery, supporting infrastructure developments that pave the way for safer, more secure transportation networks worldwide.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products