Highway Guardrail Production Equipment Supplier for Efficient Manufacturing Solutions

The Evolution of Highway Guardrail Making Machines A Manufacturer's Perspective

In the modern era, highway safety has become a paramount concern for governments and organizations worldwide. One of the crucial components of ensuring safety on the roads is the installation of guardrails. These barriers not only protect vehicles from inadvertently veering off the road but also shield pedestrians and obstacles from the high-speed traffic. Behind the production of these essential safety features lies the sophisticated machinery designed specifically for manufacturing highway guardrails. This article explores the role of highway guardrail making machines and their impact on the industry from a manufacturer's perspective.

The Importance of Highway Guardrail Making Machines

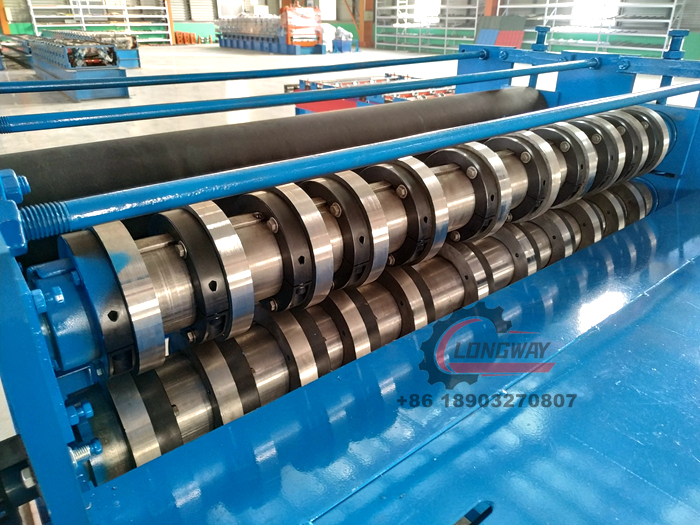

Highway guardrail making machines are specialized equipment that facilitate the efficient and precise manufacturing of guardrails. They are designed to handle various materials, primarily steel and aluminum, which are favored for their durability and strength. The process typically involves several stages, including cutting, shaping, welding, and finishing. Each phase requires high precision to ensure that the final product meets safety standards established by regulatory authorities.

As a manufacturer, understanding the significance of these machines is essential. They not only enhance productivity but also guarantee consistency in quality. An efficient guardrail making machine can produce large volumes of guardrails in a shorter timeframe, thus meeting the increasing demand driven by urban development and highway enhancements. Automation in these machines further reduces human error, improving overall safety and reliability of the guardrails produced.

Advancements in Technology

The guardrail manufacturing sector has witnessed significant technological advancements over the past decade. Modern machines are equipped with advanced features such as computer numerical control (CNC) systems that allow for precise programming and operation. This technology enables manufacturers to produce custom guardrails tailored to specific highway conditions and regulations. Other advancements include enhanced welding techniques that ensure higher strength and durability of the guardrails, as well as eco-friendly practices that minimize waste and energy consumption during production.

highway guardrail making machine manufacturer

Moreover, the integration of smart technology into these machines allows for real-time monitoring and diagnostics. Manufacturers can track machine performance, maintenance needs, and production outputs through sophisticated software applications. This capability not only streamlines operations but also boosts efficiency, allowing companies to respond more readily to market demands.

Challenges in the Manufacturing Process

Despite the technological advancements, manufacturers in the highway guardrail sector face several challenges. Fluctuating raw material prices can impact production costs and profit margins. Additionally, maintaining compliance with ever-evolving safety standards requires ongoing training and adaptation. Manufacturers must also navigate the complexities of supply chain logistics to ensure timely delivery of materials and finished products.

Furthermore, environmental sustainability is becoming increasingly important. Manufacturers are under pressure to implement sustainable practices, such as using recycled materials and reducing their carbon footprint. Adopting these practices often requires significant investment in new technologies and processes.

The Future of Highway Guardrail Making Machines

Looking ahead, the future of highway guardrail making machines appears promising. As more countries invest in infrastructure and prioritize road safety, the demand for high-quality guardrails will continue to rise. Manufacturers that embrace innovation and sustainability will be well-positioned to thrive in this dynamic market.

In conclusion, highway guardrail making machines play an integral role in producing vital safety features for roadways. Through technological advancements and a commitment to quality and sustainability, manufacturers contribute significantly to enhancing roadway safety. As the industry continues to evolve, the importance of these machines will remain a cornerstone of road safety initiatives worldwide.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025