highway guardrail machine manufacturer

Highway Guardrail Machine Manufacturers Pioneering Safety on Roads

In the modern landscape of infrastructure development, the significance of highway safety cannot be overstated. As traffic volumes rise and road networks expand, the necessity for robust safety measures becomes paramount. Among these measures, guardrails play a crucial role in protecting vehicles and passengers from potential hazards. This has led to a growing demand for specialized machinery designed specifically for the manufacturing of highway guardrails. In recent years, the role of highway guardrail machine manufacturers has become increasingly critical in ensuring the production of high-quality safety barriers.

The Importance of Highway Guardrails

Highway guardrails are essential safety installations that are designed to prevent vehicles from veering off course, reducing the risk of accidents and minimizing damage in the event of a collision. They are essential on highways, curves, and locations with steep drops. The efficiency of these safety structures is significantly influenced by their design, material quality, and manufacturing precision, which emphasizes the importance of having advanced machinery that can meet stringent industry standards.

The Manufacturing Process

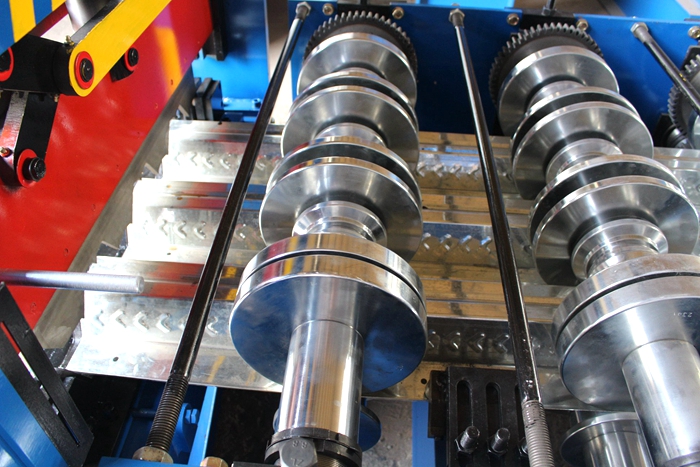

The production of guardrails involves several stages, each requiring specialized machinery and technology to ensure both efficiency and quality. Key machinery utilized in the process includes roll forming machines, welding machines, and cutting equipment.

1. Roll Forming Machines These machines are widely used to create the metal profiles needed for highway guardrails. By continuously feeding metal sheets through a series of rollers, the machines shape the material into the desired profile with great precision. The efficiency and speed of roll forming machines are essential to meet high production demands while maintaining accuracy in dimensions.

2. Welding Machines After the guardrail profiles are formed, they often require various assembly processes, including welding. Advanced welding machines ensure that joints are strong and reliable, crucial for the guardrail’s performance under stress.

3. Cutting Equipment Precise cutting is essential to create guardrail segments of various lengths. High-quality cutting machines, including automated and laser cutting options, afford manufacturers the precision necessary to meet specific project requirements.

highway guardrail machine manufacturer

Innovation and Technology

Highway guardrail machine manufacturers continue to innovate in response to ongoing industry challenges. This includes the integration of automation and robotics to enhance production efficiency and reduce labor costs. Advanced control systems allow manufacturers to streamline operations, monitor production quality in real time, and minimize waste.

Moreover, manufacturers are increasingly focusing on environmentally friendly practices by adopting sustainable materials and energy-efficient processes. The implementation of recyclable materials and the reduction of emissions in the manufacturing process are becoming industry standards, aligning with global sustainability efforts.

Selecting the Right Manufacturer

When looking for a highway guardrail machine manufacturer, several factors should be considered. Quality assurance is paramount. Manufacturers must adhere to international safety and quality standards to ensure that their machines can produce guardrails that perform effectively in real-world conditions.

Potential buyers should also evaluate a manufacturer’s technological capabilities, support services, and customization options. A manufacturer that offers comprehensive after-sales support and technical assistance can provide additional value to businesses by ensuring that machinery runs smoothly and efficiently throughout its lifecycle.

Conclusion

Highway guardrail machine manufacturers play an indispensable role in enhancing road safety by providing the necessary machinery to produce high-quality guardrails. Through continuous innovation and commitment to quality, these manufacturers ensure that the safety of road users remains a top priority. As traffic continues to increase globally, the collaboration between infrastructure development and advanced manufacturing technology will only grow more critical, fostering safer roads for future generations. Investing in the right machinery not only improves safety outcomes but also enhances the overall efficiency and success of highway infrastructure projects.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025