High-Speed Roll Forming Equipment for CD and UD Profile Production Lines

High-Speed Roll Forming Machine for CD and UD Profile Factories

In today’s fast-paced manufacturing world, efficiency and precision are crucial for meeting the ever-increasing demands of the construction and building industries. One of the pivotal innovations that have significantly enhanced production capabilities is the high-speed roll forming machine. Specifically designed for the production of Cold-formed (CD) and U-shaped (UD) profiles, these machines have revolutionized the way manufacturers approach profile production.

Understanding Roll Forming

Roll forming is a continuous bending operation in which a long strip of sheet metal is gradually shaped into the desired cross-sectional profile by passing it through a series of rollers. The process is widely used for making various structural and architectural components due to its ability to produce long lengths of uniform sections with minimal waste.

In the case of CD and UD profiles, these components are often employed in lightweight steel framing systems, providing essential support and stability in walls and ceilings. The roll forming machine's precision allows for the production of tight tolerances, ensuring that the profiles fit together seamlessly, which is vital for structural integrity.

The Advantages of High-Speed Roll Forming Machines

High-speed roll forming machines are specifically engineered to maximize output without compromising on quality. Here are some key advantages of using these advanced machines in CD and UD profile factories

1. Increased Production Efficiency A high-speed roll forming machine can produce profiles at a significantly faster rate compared to conventional methods. With the capability to operate at speeds of up to several hundred meters per minute, manufacturers can meet high-volume orders efficiently.

2. Cost-Effective Manufacturing While the initial investment in a high-speed roll forming line may be substantial, the return on investment (ROI) is often realized quickly. The reduction in labor costs due to automation, coupled with the material savings from precise cutting and minimal wastage, enhances overall profitability.

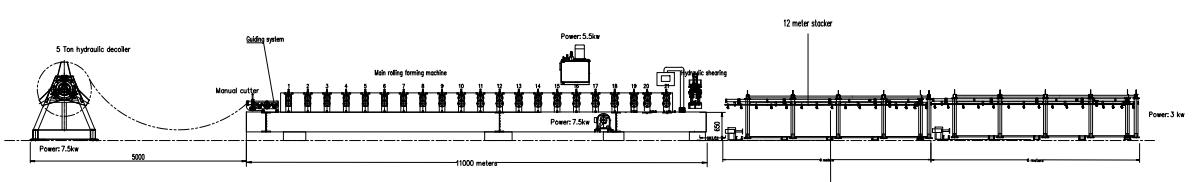

high speed roll forming machine for cd ud profile factories

3. Flexibility and Versatility Modern roll forming machines come equipped with advanced controls that allow manufacturers to easily switch between different profile designs. This versatility is especially beneficial for businesses that may receive varied orders or need to adapt to changing market demands.

4. High Precision and Consistency With computer numerical control (CNC) technology, high-speed roll forming machines can produce profiles to exact specifications consistently. This precision reduces the likelihood of defects, leading to higher quality finished products.

5. Reduced Labor Costs Automating the roll forming process minimizes the manual labor required, allowing for a lean manufacturing approach. This shift not only cuts down on labor costs but also streamlines workflows, enabling employees to focus on more complex tasks.

Applications of CD and UD Profiles

CD and UD profiles are extensively used in various applications, including

- Lightweight Steel Framing These profiles are essential components in constructing non-load-bearing walls, ceilings, and partitions in commercial and residential buildings. - Suspended Ceiling Systems CD profiles are commonly used as support channels in suspended ceiling installations, providing a sturdy framework for ceiling panels. - Track and Support Systems UD profiles serve as the vertical tracks in wall systems, ensuring that the entire structure remains aligned and secure.

Conclusion

As construction industries continue to evolve, the demand for efficient, high-quality building components grows. High-speed roll forming machines tailored for CD and UD profiles offer manufacturers an innovative solution to meet these demands head-on. By enhancing production speed, reducing costs, and ensuring high precision, these machines play a pivotal role in shaping the future of the construction industry.

In summary, investing in high-speed roll forming technology is not just a step towards modernizing manufacturing processes; it is a commitment to quality, efficiency, and future growth in an increasingly competitive market. For companies looking to stay ahead, embracing this technology is imperative.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025