High-Quality Sheet Metal Roofing Machines Available for Purchase at Competitive Prices Today

The Advantages of Investing in Sheet Metal Roofing Machines

In the construction and manufacturing industry, the demand for durable and efficient roofing solutions has led to the growing popularity of sheet metal roofing. As a result, sheet metal roofing machines have emerged as essential tools for manufacturers aiming to stay competitive in this thriving market. Investing in a sheet metal roofing machine can offer numerous advantages, from increased production efficiency to enhanced product quality. This article explores the benefits and considerations of acquiring a sheet metal roofing machine for sale.

Increased Production Efficiency

One of the most significant advantages of a sheet metal roofing machine is its ability to streamline the production process. These machines are designed to automate various aspects of roofing manufacturing, from cutting and shaping to forming and finishing. This automation reduces labor costs and minimizes human error, resulting in a more efficient production line. As a result, manufacturers can significantly increase their output, allowing them to meet market demands more effectively and potentially expand their customer base.

Moreover, modern sheet metal roofing machines are equipped with advanced technology such as computer numerical control (CNC), which enables precise and repeatable cuts

. This precision ensures that every roofing panel produced meets stringent quality standards, allowing businesses to maintain a consistent level of product quality that enhances their reputation in the market.Versatility and Customization

Sheet metal roofing machines come with the capacity to produce a variety of styles and profiles, catering to a wide range of architectural designs and customer preferences. This versatility allows manufacturers to tap into different market segments, from residential homes to commercial buildings. Options such as standing seam, corrugated, and tile profiles can all be produced with the same machine, providing flexibility in product offerings.

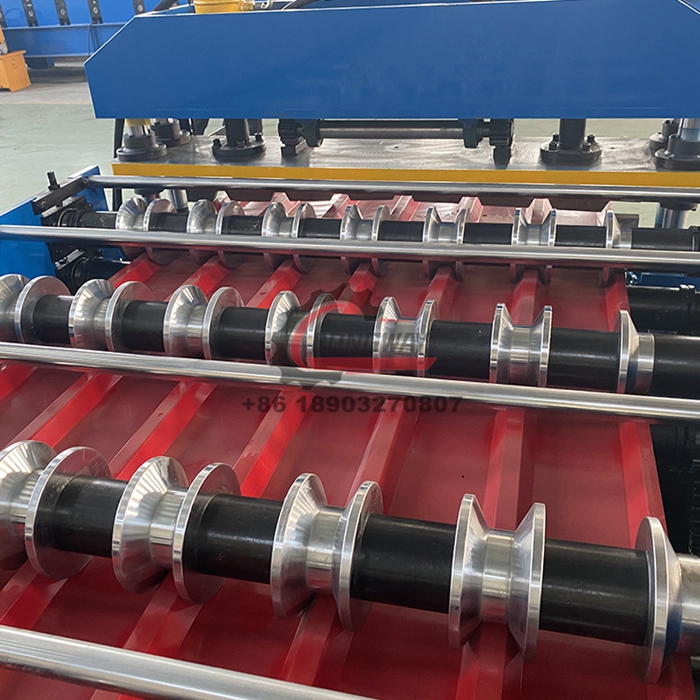

sheet metal roofing machine for sale

Customization is another vital benefit. Many modern machines can be programmed to create unique designs, enabling manufacturers to fulfill specific customer requests and stand out from competitors. This ability to customize products not only attracts more clients but also helps businesses adapt to evolving trends in the roofing industry.

Cost Savings

While the initial investment in a sheet metal roofing machine may seem substantial, the long-term cost savings can be significant. By increasing production efficiency and reducing labor costs, businesses can achieve a quicker return on investment. Additionally, the durability of sheet metal roofing reduces the frequency of repairs and replacements, leading to lower long-term maintenance costs for end-users. Manufacturers who provide high-quality roofing solutions benefit from fewer warranty claims and increased customer satisfaction, ultimately contributing to their bottom line.

Market Demand and Eco-Friendliness

The global trend toward environmentally sustainable building practices has bolstered the demand for sheet metal roofing. Metal roofs are known for their longevity, recyclability, and energy efficiency. By using a sheet metal roofing machine, manufacturers not only cater to this rising demand but also play a part in promoting eco-friendly construction. This benefit can enhance a business’s reputation among environmentally conscious consumers, providing a competitive edge in the marketplace.

Conclusion

Investing in a sheet metal roofing machine for sale presents a valuable opportunity for manufacturers looking to enhance their production capabilities and product offerings. With advantages such as increased efficiency, versatility, cost savings, and alignment with sustainable practices, these machines can significantly impact a business's success. As the roofing industry continues to evolve, investing in high-quality equipment will be essential for manufacturers aiming to thrive in this competitive landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025