High-Quality Roll Forming Machine for Custom Shutter Doors with Advanced Technology and Design Features

The Importance of Custom Shutter Door Roll Forming Machines

In the modern manufacturing landscape, efficiency and customization play crucial roles in meeting the diverse needs of businesses. One significant innovation in this domain is the custom shutter door roll forming machine. These machines are designed to produce high-quality shutter doors tailored to specific requirements, thereby revolutionizing the way security products are manufactured.

What is a Roll Forming Machine?

Roll forming is a process in which metal is continuously bent to achieve a desired cross-sectional profile. A roll forming machine consists of a series of rollers that gradually shape the metal strip into the desired form. When it comes to shutter doors, these machines can fabricate various designs, ensuring that the final product meets both aesthetic and functional criteria.

Advantages of Custom Shutter Door Roll Forming Machines

1. Tailored Solutions One of the most significant benefits of using a custom roll forming machine is the ability to produce doors that precisely match the specifications provided by clients. Whether it’s a specific thickness, profile design, or color, customization allows manufacturers to cater to the unique requirements of different industries, from retail to industrial applications.

2. Efficiency and Speed Custom roll forming machines are designed to operate at high speeds, significantly reducing production times. Multiple doors can be produced simultaneously, which not only boosts output but also enhances the overall efficiency of the manufacturing process. This rapid production capability is vital in industries that require quick turnaround times for security installations.

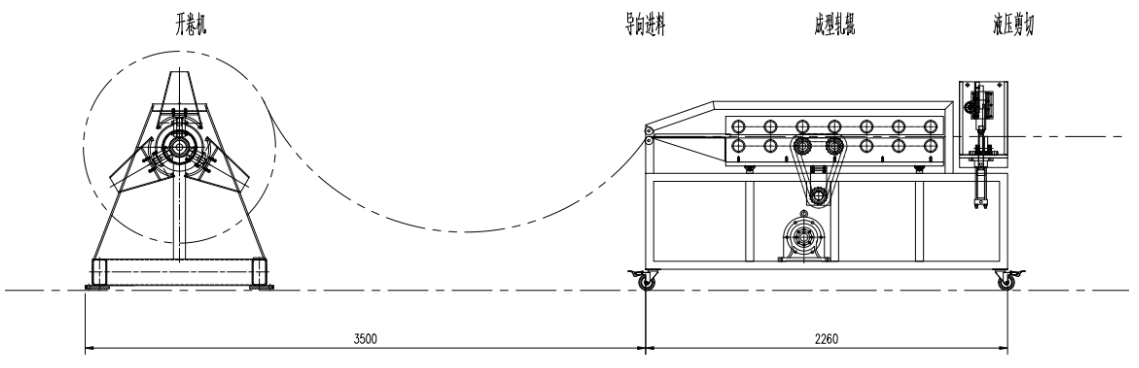

custom shutter door roll forming machine

3. Cost-Effectiveness While the initial investment in a custom roll forming machine might be substantial, the long-term savings are notable. By streamlining the manufacturing process and minimizing waste materials, manufacturers can reduce theirOverall production costs. Additionally, the durability of the doors produced means fewer replacements over time.

4. Enhanced Durability and Security The materials utilized in roll forming, typically high-grade steel or aluminum, result in products that boast superior strength and durability. Custom shutter doors manufactured from these materials are capable of withstanding harsh weather conditions and potential break-in attempts, providing an excellent solution for businesses that prioritize security.

5. Innovative Designs With advancements in technology, modern roll forming machines can incorporate various design features, such as slats for ventilation or decorative elements. This flexibility not only enhances the visual appeal of the doors but also allows for increased functionality, catering to specific client needs.

Applications of Custom Shutter Door Roll Forming Machines

Custom shutter doors produced with roll forming machines are invaluable in various applications. Retail establishments often use them for storefront security, ensuring products are protected after hours. In warehouses, these doors provide security and temperature control, while residential properties may require them for garages or patios. With the growing emphasis on safety and aesthetics, the demand for customized shutter doors continues to rise.

Conclusion

As industries evolve and the need for customized security solutions increases, the role of custom shutter door roll forming machines becomes ever more critical. By offering tailored, efficient, and durable solutions, these machines represent the future of door manufacturing. Businesses looking to enhance their security offerings while maintaining aesthetic appeal would do well to consider the advantages provided by custom roll forming technology. In an era where personalization and efficiency are paramount, embracing such innovations can lead to a competitive edge in the marketplace.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025