High-Quality Mobile Metal Roof Roll Forming Machine Available from Leading Manufacturers for Sale

Portable Metal Roof Roll Forming Machine A Comprehensive Overview for Buyers

In the ever-evolving construction and manufacturing sectors, the demand for efficient, reliable, and versatile machinery has never been greater. One standout piece of equipment that has garnered significant attention is the portable metal roof roll forming machine. This machine not only revolutionizes the way roofing materials are produced but also enhances productivity and efficiency on job sites. In this article, we will explore the features, benefits, and key considerations for those looking to purchase such a machine.

Understanding Portable Metal Roof Roll Forming Machines

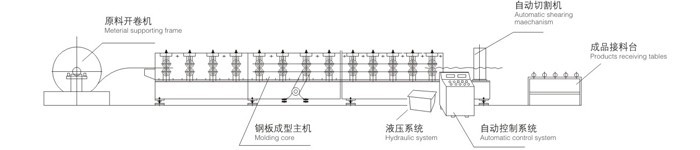

A portable metal roof roll forming machine is a specialized piece of equipment designed for the continuous production of metal roofing sheets. These machines work by forming metal coils, typically made from steel or aluminum, into desired shapes and profiles while maintaining precision in size and consistency. The “portable” aspect refers to the machine's ability to be easily transported to various job sites, allowing for on-demand production. This eliminates the need for transporting heavy materials from a manufacturing facility, thus saving time and reducing costs.

Key Features and Advantages

1. Versatility Portable metal roof roll forming machines can produce a wide array of panel profiles, making them suitable for different roofing styles and architectural designs. Whether you need standing seam, corrugated panels, or flat sheets, these machines can accommodate various needs with only minor adjustments.

2. Efficiency and Speed With the capability to produce roofing materials on-site, these machines significantly reduce lead times. Projects can be completed faster, which is crucial in today’s fast-paced construction environment. This not only enhances customer satisfaction but also improves overall project efficiency.

3. Cost-Effectiveness By reducing transportation costs and minimizing waste during production, portable roll forming machines offer significant savings in the long run. Moreover, their capability to produce materials on demand minimizes the financing of inventory.

4. User-Friendly Design Most modern portable roll forming machines are designed with user-friendliness in mind. They often come with intuitive controls, making it easier for operators to get up to speed quickly. Training costs are reduced, and even personnel with minimal experience can operate the machine effectively after a short learning curve.

5. Quality Assurance These machines are engineered to produce high-quality roofing panels consistently. Advanced technology ensures that the materials conform to industry standards and specifications, reducing the likelihood of defects.

portable metal roof roll forming machine for sale manufacturer

Considerations When Purchasing

When looking to invest in a portable metal roof roll forming machine, several key factors should be taken into account

1. Production Capacity Assess your anticipated workload and choose a machine with the appropriate production capacity. Whether you need a machine for small projects or large-scale operations, selecting the right capacity is crucial for meeting demand.

2. Material Compatibility Ensure that the machine you choose can handle the types of materials you plan to use. Check for specifications regarding thickness and material types.

3. Ease of Transportation Consider the weight and size of the machine and how easily it can be transported to different job sites. Compact and lightweight models are preferable for frequent relocation.

4. Technical Support Opt for reputable manufacturers who offer reliable customer support, including training, maintenance, and repair services. This is essential for minimizing downtime and maximizing productivity.

5. Cost vs. Value While price is a significant factor, it should not be the sole consideration. Look at the overall value offered by different machines, including their features, support, and long-term durability.

Conclusion

Investing in a portable metal roof roll forming machine is a strategic move for contractors and manufacturers looking to enhance their operational efficiency and product quality. By understanding the machine’s features, advantages, and critical purchasing factors, buyers can make informed decisions that lead to lasting benefits for their businesses. In an industry where time and quality are of the essence, the right machinery can make all the difference.

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025