High-Quality Drip Edge Roll Forming Machine Manufacturing for Efficient Roofing Solutions

Drip Edge Roll Forming Machine Factory Revolutionizing Construction with Precision Manufacturing

In the ever-evolving construction industry, the need for efficient, durable, and precise building materials is paramount. Among the various components that play a crucial role in roofing systems, the drip edge is essential for preventing water damage and ensuring the longevity of structures. This is where the drip edge roll forming machine comes into play, significantly impacting the way construction materials are produced.

What is a Drip Edge Roll Forming Machine?

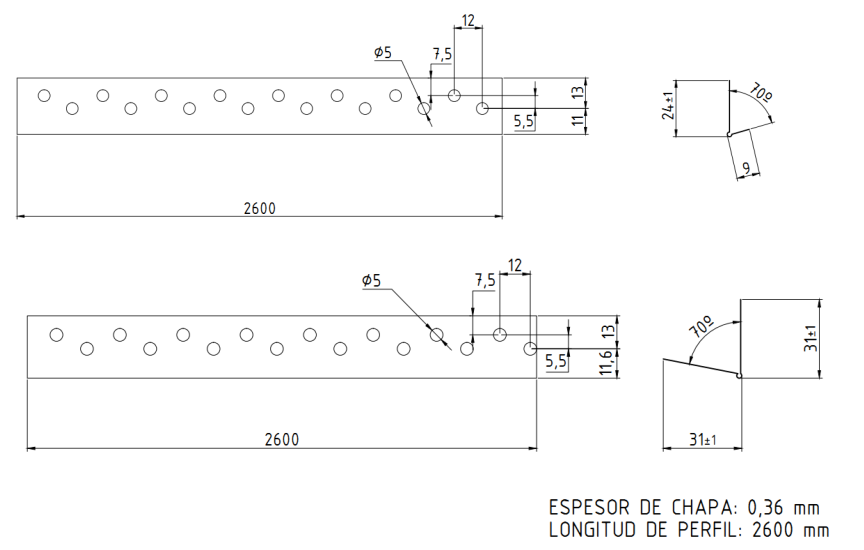

A drip edge roll forming machine is a specialized piece of equipment designed to shape metal sheets into a specific profile known as a drip edge. This component is installed at the edge of a roof and functions to channel water away from the fascia and into the gutters, thereby minimizing potential water damage to the underlying structure. The roll forming process is a continuous operation that bends and shapes metal strips into the desired profile, making it an efficient method for producing high volumes of drip edges quickly and consistently.

Benefits of Using a Drip Edge Roll Forming Machine

The advantages of utilizing a drip edge roll forming machine are manifold. First and foremost, these machines offer high precision. With advanced technology and automated systems, manufacturers can achieve tight tolerances that ensure the drip edges fit perfectly during installation. This precision not only enhances the aesthetic appeal of the roofing but also its functional efficiency.

Furthermore, roll forming machines are renowned for their speed and efficiency. Unlike other manufacturing processes that may involve multiple steps and significant downtime, roll forming is continuous. This translates to higher production rates and lower labor costs, allowing factories to meet the increasing demand in the construction sector without sacrificing quality.

drip edge roll forming machine factory

Durability is another key advantage. The materials used in drip edge production, typically galvanized steel or aluminum, can be treated to resist corrosion and weathering. This ensures that the drip edges maintain their structural integrity over time, protecting buildings from the elements.

The Role of Factories in Modern Construction

The factory environment for producing drip edge roll forming machines is geared towards optimizing production efficiency and maintaining high standards. Modern factories are equipped with cutting-edge technology that facilitates the production process, from raw material handling to the final product inspection. Skilled technicians monitor the operations, ensuring that every piece meets rigorous quality control standards.

Moreover, factories are increasingly adopting sustainable practices, such as minimizing waste and recycling materials. By utilizing advanced manufacturing techniques, they can reduce the environmental impact of production while still delivering high-quality materials to the construction industry.

The Future of Drip Edge Roll Forming

As the construction industry continues to expand, the demand for specialized components like drip edges is only set to increase. The roll forming technology is likely to evolve, with innovations in material science and automation paving the way for even faster and more efficient production processes. These advancements will not only enhance the capabilities of manufacturers but will also contribute to the overall quality of construction materials available on the market.

In conclusion, the drip edge roll forming machine factory serves as a pivotal element in modern construction, combining precision engineering with the need for efficiency and quality. As technology advances, these factories will play an increasingly critical role in shaping the future of the construction industry, ensuring that buildings are not only aesthetically pleasing but also resilient against the forces of nature.

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025