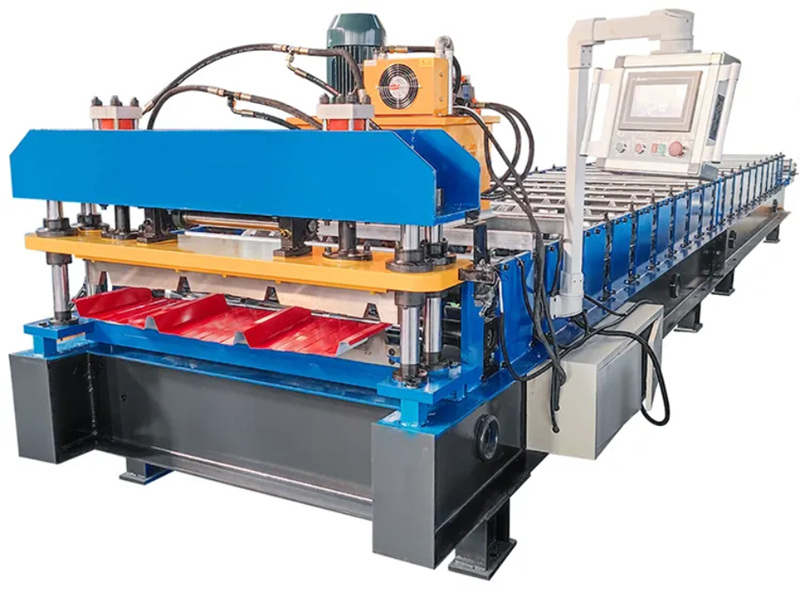

High-Quality Door Frame Roll Forming Machine Manufacturer for Efficient Production Solutions

The Door Frame Roll Forming Machine A Key to Efficient Production

In the world of manufacturing, efficiency and precision are paramount, especially when it comes to producing components for construction. One such innovation that has revolutionized the production of door frames is the door frame roll forming machine. This machine plays a critical role in ensuring that door frames are produced with high accuracy and at a rapid pace, meeting the growing demands of the construction industry.

Understanding Roll Forming Technology

Roll forming is a continuous bending operation in which a long strip of metal, usually steel, aluminum, or other materials, is passed through sets of rollers that gradually shape it into the desired profile. The door frame roll forming machine utilizes this technology to create door frames that are not only structurally sound but also aesthetically pleasing. The process involves several stages, including feeding, forming, cutting, and finishing. This comprehensive approach ensures that the final product meets the necessary specifications.

Key Features of Door Frame Roll Forming Machines

Modern door frame roll forming machines come equipped with advanced technology designed to enhance productivity. These features typically include

1. Automated Control Systems These systems allow manufacturers to operate the machines with minimal human intervention, increasing efficiency and reducing the risk of errors. 2. High-Speed Production Depending on the design and specifications, a roll forming machine can produce door frames at impressive speeds, making it suitable for large-scale manufacturing.

3. Versatility Many roll forming machines can be adjusted to produce various types and sizes of door frames, accommodating a wide range of projects.

5. Eco-Friendly Processes As sustainability becomes increasingly important in manufacturing, many door frame roll forming machines are designed to minimize waste and energy consumption.

door frame roll forming machine factory

Applications in the Construction Industry

Door frames are essential components in residential and commercial buildings, serving both functional and aesthetic purposes. Roll-formed door frames are particularly advantageous due to their strength, lightweight nature, and resistance to warping and corrosion. These frames can be used in various settings, including

- Residential Buildings Roll-formed door frames are ideal for homes, providing sturdy structures that complement interior designs.

- Commercial Spaces In offices and retail spaces, these frames offer a professional finish that can enhance the overall appearance of a building.

- Industrial Applications In warehouses and manufacturing facilities, durable door frames are crucial for ensuring security and accessibility.

Investing in a Door Frame Roll Forming Machine

For manufacturers looking to invest in a door frame roll forming machine, it is essential to consider factors such as production capacity, customization options, and after-sales support. Collaborating with a reputable machine factory can provide the assurance of quality and advanced technology. Furthermore, understanding the specific needs of the market will help in selecting the right machine to optimize production processes.

Conclusion

The door frame roll forming machine is a vital asset in the manufacturing sector, especially for those involved in the construction industry. By enabling efficient and precise production of door frames, it contributes significantly to both the quality of buildings and the efficiency of manufacturing operations. As technology continues to evolve, so too will the capabilities of these machines, fostering innovation and progress in the construction landscape. Investing in such technology not only benefits manufacturers but ultimately enhances the built environment, providing consumers with durable and high-quality products.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025