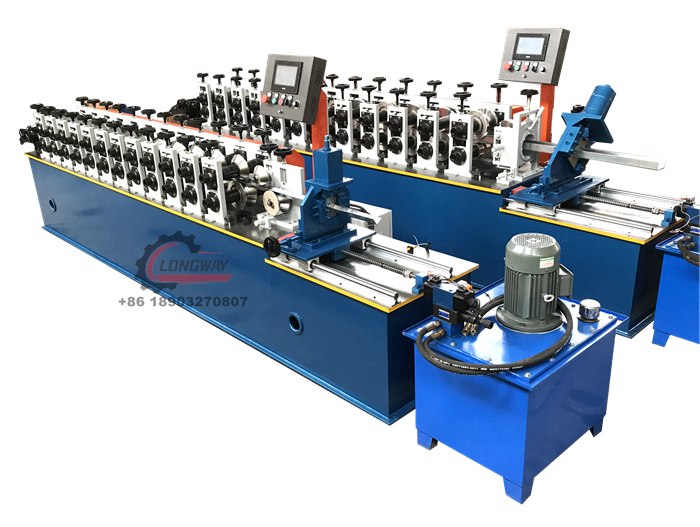

High-Quality Deck Roll Forming Machine Production in a Leading Factory Setting

The Evolution and Importance of Deck Roll Formers in Modern Manufacturing

In the realm of modern manufacturing, specialized machinery plays a crucial role in producing high-quality materials efficiently. Among these machines, the deck roll former is integral, particularly in the construction and architectural industries. This article explores the significance of deck roll forming and the workings of a specialized factory that manufactures these vital tools.

Understanding Deck Roll Forming

Deck roll forming is a process that shapes metal coils into precision-engineered profiles used primarily in floor and roof decking systems. This process involves feeding metal strips through a series of rollers that gradually shape the metal into specific configurations, which enhances strength and durability. The result is lightweight yet robust materials that are essential for creating safe, reliable structural frameworks.

Roll forming has gained popularity for its efficiency and ability to produce consistent quality, making it an ideal method for large-scale manufacturing. A well-designed deck roll former can produce a wide variety of profiles with minimal waste, which is increasingly important in today's environmentally conscious society.

The Role of Deck Roll Former Factories

A deck roll former factory is a specialized facility dedicated to the design and manufacture of roll forming machines. These factories not only produce machinery but also provide technical support, maintenance services, and often customization options to meet specific client needs. The production process within such factories typically involves several key steps

1. Design Engineers collaborate to create detailed blueprints for roll forming machines, taking into account the specific requirements of clients. This includes considerations for the types of material to be formed, thicknesses, and desired profiles.

2. Fabrication Once the designs are finalized, skilled technicians commence the fabrication process. This involves cutting, bending, and welding raw materials to construct the machine frame and rollers. Advanced technology, including CNC machinery, is often employed to ensure precision.

deck roll former factory

3. Assembly After fabrication, the components are assembled meticulously. Each part is calibrated to guarantee that the machine operates smoothly and produces high-quality end products.

4. Testing Quality assurance is paramount in a deck roll former factory. Each machine undergoes rigorous testing to verify its performance, including speed, accuracy, and durability. This step ensures that the final product meets industry standards and client expectations.

5. Delivery and Support Once a machine passes testing, it is packaged and shipped to the client’s location. Post-delivery support is critical, as factory experts often provide training and troubleshooting assistance to ensure successful operation.

The Impact on the Industry

Deck roll former factories contribute significantly to the construction and manufacturing sectors by promoting efficiency and productivity. The ability to produce custom profiles on demand helps companies respond rapidly to market changes, reduce lead times, and optimize their supply chains.

Moreover, the investment in advanced roll forming technology fosters innovation within the construction industry. New profiles and materials can lead to innovative building solutions, such as eco-friendly construction methods or enhanced seismic resistance.

Conclusion

In summary, the role of deck roll former factories is indispensable in modern manufacturing. By producing high-quality roll forming machinery, these factories enable the efficient creation of vital construction materials. As the demand for innovative building solutions continues to grow, investment in this specialized manufacturing sector will undoubtedly play a pivotal role in shaping the future of construction and architecture. The ongoing evolution of deck roll forming technology promises to enhance the durability and efficiency of structures, laying the groundwork for a more sustainable built environment.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025