High-Quality Customized Corrugated Sheet Forming Machine for Efficient Production and Durability

Custom Corrugated Sheet Forming Machine Revolutionizing Sheet Production

In the rapidly evolving world of manufacturing, custom machinery plays a pivotal role in enhancing efficiency and precision in production. One of the standout examples of such innovation is the custom corrugated sheet forming machine. This specialized equipment is designed to create corrugated sheets tailored to specific industrial needs, providing solutions for a variety of applications, including packaging, construction, and automotive industries.

What is a Corrugated Sheet Forming Machine?

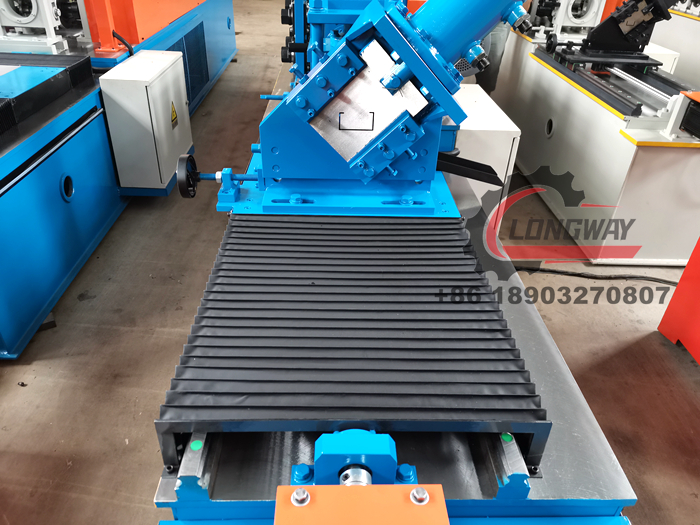

A corrugated sheet forming machine is a sophisticated piece of equipment that reshapes flat materials into corrugated forms, which are characterized by their wavy or ribbed structure. This design significantly increases the strength and durability of the sheets while minimizing material usage. Customization can be achieved in various ways, including adjustments to the thickness, width, material type, and the shape of the corrugation itself.

The machine operates through a series of rollers and dies that shape the sheet as it passes through the forming stations. The intricate design of these machines allows manufacturers to produce sheets that meet specific dimensional and mechanical requirements, making them invaluable in industries that demand high-performance materials.

Benefits of Customization

The primary advantage of using a custom corrugated sheet forming machine lies in its ability to produce tailored solutions for different applications. For instance, a packaging company may require lightweight yet strong corrugated sheets for shipping products. In contrast, a construction firm might need thicker sheets to provide better insulation and support. Custom machines can adapt to these varying demands, ensuring that manufacturers have the exact specifications needed for their projects.

Additionally, the ability to control the production process means that companies can significantly reduce waste, optimize material usage, and maintain a lean production line

. This not only benefits the environment by reducing excess scrap but also leads to cost savings for manufacturers.custom corrugated sheet forming machine

Technological Advancements

Recent advancements in technology have further enhanced the capabilities of custom corrugated sheet forming machines. Integration of automation and smart technology allows for real-time monitoring and adjustments during the production process. This means that manufacturers can ensure consistent quality while also being able to respond to changes in demand swiftly.

Furthermore, some machines are now equipped with advanced software that enables designers to visualize and simulate the production process before actual manufacturing begins. This feature helps in identifying potential issues earlier in the design phase, ultimately leading to a smoother production experience.

Industries Impacted

The applications of custom corrugated sheet forming machines span across multiple industries. In the packaging sector, corrugated sheets provide structural integrity for shipping boxes and displays. In construction, these sheets are often utilized for roofing and wall design due to their lightweight nature and insulation properties. In the automotive industry, custom corrugated solutions can be found in various applications, including protective components and internal structure elements.

Conclusion

In conclusion, the custom corrugated sheet forming machine represents a significant advancement in manufacturing technology. By enabling the production of tailored corrugated sheets that meet specific industry needs, this machine not only enhances efficiency but also allows for greater creativity and innovation in product design. As industries continue to evolve and demand more sophisticated materials, the importance of such custom machinery will only increase, driving further advancements in techniques and technology in the manufacturing sector. As businesses embrace these innovations, we can expect to see a continued emphasis on sustainability, efficiency, and quality in production processes.

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025