High-Quality 7-Inch Box Gutter Machine Available for Purchase at Competitive Pricing

The Growing Demand for 7-Inch Box Gutter Machines An Investment in Quality and Efficiency

In the world of construction and roofing, proper drainage is crucial to the longevity and integrity of any structure. One of the key components in directing water away from roofs and safeguarding buildings from water damage is the gutter system. Among the various types of gutter systems, the box gutter stands out for its sleek design and efficient water management capabilities. As the demand for high-quality building materials and solutions grows, the market for 7-inch box gutter machines has also seen a significant increase.

What is a Box Gutter?

Box gutters are a type of roof drainage system that is often installed at the junction of a sloped roof and a vertical wall. Unlike traditional K-style gutters, box gutters have a rectangular shape, which allows for greater water capacity and minimizes overflow during heavy rain. Their aesthetic appeal also makes them a popular choice in residential, commercial, and historical buildings. As a result, the need for reliable and efficient box gutter machinery has become paramount for manufacturers and contractors alike.

The Importance of a 7-Inch Box Gutter Machine

A 7-inch box gutter machine is specifically designed to fabricate box gutters with a width of 7 inches, a common size that balances capacity with ease of installation. These machines are vital for producing consistent, high-quality gutters that meet the rigorous demands of modern construction projects. The benefits of investing in a 7-inch box gutter machine include

1. Precision Engineering These machines are capable of producing gutters with exact dimensions, reducing the likelihood of errors during installation. Consistency in size ensures that every gutter fits seamlessly, which is vital for both aesthetics and functionality.

2. Increased Efficiency With advanced technology and automation features, a 7-inch box gutter machine can produce a large volume of gutters in a short amount of time. This efficiency translates to cost savings for manufacturers and faster project completion for contractors.

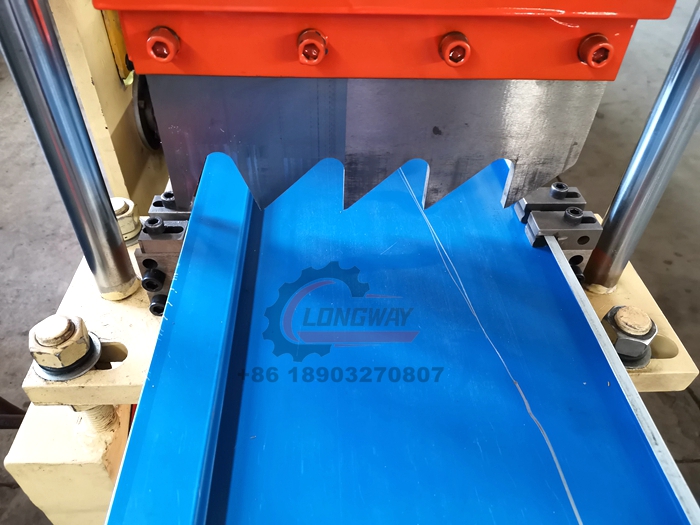

7 inch box gutter machine for sale

3. Material Versatility Many modern box gutter machines can work with various materials, including aluminum, copper, and steel. This flexibility allows contractors to meet specific client requests and project requirements without needing multiple machines.

4. Durability and Strength The robust construction of 7-inch box gutter machines ensures long-term reliability. Built to handle high demands, these machines require minimal maintenance, allowing businesses to focus on production without unexpected downtimes.

Market Trends and Considerations

As more builders and homeowners prioritize quality in construction, the trend toward high-capacity and aesthetically pleasing box gutters is expected to continue. This creates a lucrative market for those who manufacture and sell 7-inch box gutter machines. For contractors and manufacturers considering an investment in such machinery, it is crucial to evaluate machine specifications, after-sales service, and the reputation of the supplier.

Additionally, with the growing focus on sustainability and eco-friendly practices, incorporating energy-efficient machinery and using recyclable materials for production can enhance a business’s appeal. This not only meets the current market demands but positions the business as a forward-thinking leader in the industry.

Conclusion

In summary, the 7-inch box gutter machine is more than just a piece of equipment; it's a gateway to increasing operational efficiency, enhancing product quality, and boosting a business's competitiveness in the construction sector. With the swimming pool of projects requiring effective drainage solutions, investing in a high-quality box gutter machine could be a strategic move that pays dividends in the long run. As the market continues to expand, so too will the opportunities for those equipped to meet these demands.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025