High-Performance Purlin Roll Forming Machine for Custom Profiles

The Future of Metal Fabrication Profile Purlin Roll Machines

In recent years, the construction and manufacturing industries have seen significant advancements in technology and machinery. One such innovation that has gained considerable attention is the profile purlin roll machine. This sophisticated piece of equipment is designed to produce high-quality purlins used in steel structures, providing a robust solution for various building and roofing applications.

Understanding Profile Purlins

Profile purlins are essential components in the construction sector, primarily used to support roofs and walls. They are typically made from galvanized steel, which offers excellent durability and resistance to corrosion. Purlins come in different shapes and sizes, including C and Z profiles, allowing for versatility in application. The use of purlins enhances the load-bearing capacity of structures while reducing the overall weight, making them an ideal choice for modern buildings.

The Role of a Profile Purlin Roll Machine

A profile purlin roll machine automates the manufacturing process of purlins. The machine rolls steel sheets into desired shapes, minimizing manual labor and increasing production efficiency. The key advantage of using a roll machine is its ability to create consistent and precise profiles, which are crucial for structural integrity. The process involves feeding a flat steel sheet into the machine, where it undergoes a series of rollers that gradually shape it into the desired purlin profile.

This machinery not only streamlines production but also significantly reduces waste. Traditional methods of cutting and shaping materials can lead to excessive scrap, whereas roll forming utilizes the entire sheet, resulting in cost savings.

Advancements in Technology

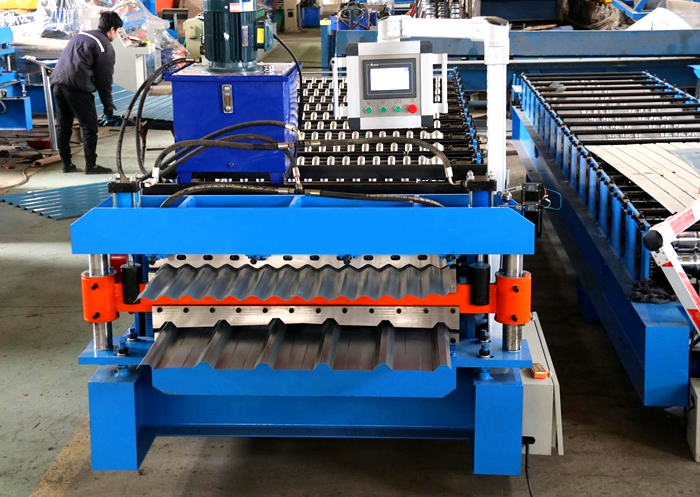

profile purlin roll machine

Modern profile purlin roll machines are equipped with advanced features that enhance their functionality. For instance, many machines now incorporate computer numerically controlled (CNC) systems, allowing for precise adjustments and programming. Operators can easily input specifications for different purlin sizes, and the machine will automatically adjust its settings, ensuring accuracy and consistency across production runs.

Additionally, some roll machines come with integrated punching and cutting systems, enabling simultaneous shaping and perforation of the purlins. This integration not only saves time but also enhances the overall production process.

Applications in the Industry

The applications of profile purlin roll machines are vast, impacting various sectors within construction. From commercial buildings to agricultural structures, the need for reliable and durable purlins is ever-present. These machines are particularly beneficial in projects requiring rapid construction schedules, as they facilitate quick and efficient manufacturing.

In the realm of residential construction, purlins produced by roll machines contribute to the creation of sturdy roofs and frameworks, enhancing the longevity and safety of homes. Furthermore, with the rising emphasis on sustainable building practices, the use of steel purlins, which are recyclable and require less energy to produce compared to other materials, aligns with the industry's move towards eco-friendly solutions.

Conclusion

Profile purlin roll machines are revolutionizing the way purlins are manufactured, offering a blend of efficiency, precision, and cost-effectiveness. As technology continues to advance, these machines will likely become even more sophisticated, paving the way for innovations in the construction industry. With the ability to produce high-quality, sustainable materials, profile purlin roll machines play a vital role in shaping the future of metal fabrication, driving advancements that support modern building needs while adhering to environmental standards. As the demand for efficient construction solutions grows, adopting such innovative machinery will undoubtedly remain a key factor in the industry's evolution.