High-Efficiency 988 Corrugated Roofing Sheet Forming Machine

Precision Roll Forming: The Core of Modern Roofing Manufacturing

In the dynamic landscape of modern construction, the demand for high-quality, durable, and efficiently produced roofing materials continues to grow exponentially. Corrugated roofing sheets stand as a cornerstone of this demand, offering unparalleled strength-to-weight ratios, excellent weather resistance, and cost-effectiveness for a vast array of applications, from industrial facilities and agricultural structures to residential buildings in developing regions. The efficiency and precision with which these sheets are produced directly impact project timelines, material waste, and ultimately, the structural integrity of the final build. Central to this manufacturing prowess is the sophisticated technology of roll forming, a cold-forming process that transforms flat sheet metal coils into intricate profiles with consistent accuracy. Industry trends highlight a significant shift towards greater automation, enhanced material versatility, and superior energy efficiency in roll forming machinery. Manufacturers are increasingly seeking solutions that not only meet stringent quality standards but also offer adaptability to diverse material specifications and reduce operational costs. This pursuit of excellence drives the innovation behind specialized equipment designed to produce specific profiles, such as the 988 Corrugated roofing sheet forming machine. This advanced machinery represents the pinnacle of engineering in the corrugated roofing sector, addressing the evolving needs for speed, precision, and economic viability in large-scale production environments. Its integration into manufacturing lines signifies a commitment to leveraging cutting-edge technology to deliver superior products, ensuring that construction projects worldwide benefit from robust and reliable roofing solutions that stand the test of time and environmental challenges, while adhering to global sustainability practices through minimized waste and optimized resource utilization in the production cycle.

Technical Specifications and Operational Mechanics of the 988 Model

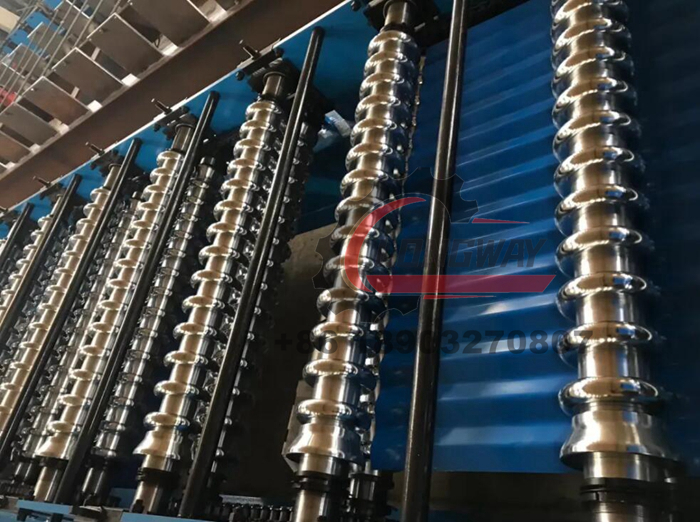

The design and engineering of the 988 Corrugated roofing sheet forming machine are meticulously tailored to achieve optimal performance and consistent output quality, making it a critical asset for high-volume roofing material production. This machine operates on a sequential cold roll forming principle, where a flat metal coil is incrementally shaped by a series of precisely engineered roller dies. Each set of rollers progressively bends the metal into the desired 988 corrugated profile without the application of heat, thus preserving the material's inherent strength and structural integrity. Key components include an uncoiler, which feeds the raw material smoothly into the system; a guiding system that ensures accurate alignment; the main roll forming station, comprising multiple sets of forming rollers fabricated from high-grade alloy steel and often hard chrome-plated for enhanced durability and wear resistance; a cutting device, typically hydraulic or pneumatic, designed for precise, burr-free cuts; and an automatic stacking system for finished sheets. The hydraulic system provides stable and powerful operation for both cutting and pre-punching functions, while the advanced PLC (Programmable Logic Controller) control system, often featuring a touchscreen interface, allows for intuitive operation, precise length settings, batch production programming, and real-time monitoring of machine parameters. This integration of robust mechanical components with intelligent electronic controls ensures that the 988 Corrugated roofing sheet forming machine delivers exceptional precision, operational efficiency, and a high degree of automation, minimizing manual intervention and maximizing throughput. The careful selection of materials for critical parts, such as Cr12MoV for rollers and Q235 for the frame, underscores a commitment to longevity and performance under continuous heavy-duty use. The comprehensive parameter table below provides a detailed overview of the machine's capabilities and specifications, offering insights into its capacity and design considerations for potential adopters in the roofing manufacturing sector.

| Parameter | Specification |

|---|---|

| Roll Forming Speed | 15-25 m/min (adjustable) |

| Material Thickness Range | 0.3 - 0.8 mm (GI, PPGI, Aluminum) |

| Material Width (Coil) | 1250 mm |

| Effective Width of Sheet | 988 mm |

| Roller Stations | Approximately 16-18 sets |

| Roller Material | Cr12MoV (Quenched and Hard Chrome Plated) |

| Main Motor Power | 5.5 kW - 7.5 kW (depending on configuration) |

| Hydraulic Station Power | 3 kW - 4 kW |

| Controlling System | PLC with Touch Screen (e.g., Siemens, Panasonic) |

| Overall Dimensions (Approx.) | 8000mm x 1500mm x 1500mm |

| Total Weight (Approx.) | 6500 kg - 8000 kg |

Manufacturing Process and Quality Assurance for Durability

The robust performance and extended service life of a 988 Corrugated roofing sheet forming machine are direct outcomes of the meticulous manufacturing processes and stringent quality control standards applied during its construction. The foundation of this machine's durability lies in the selection of premium-grade materials. The main frame, often constructed from high-strength structural steel like Q235 or higher grades, undergoes precise cutting, multi-pass welding with strict adherence to AWS (American Welding Society) or equivalent international standards, and subsequent stress-relief annealing to prevent deformation and enhance structural stability over decades of operation. Critical components such as the rollers, which are central to the machine's shaping capabilities, are typically forged from high-carbon, high-chromium tool steel, such as Cr12MoV. This material is chosen for its exceptional hardness and wear resistance. Following forging, these rollers undergo a rigorous heat treatment process, including quenching and tempering, to achieve a uniform hardness (often HRC 58-62), significantly extending their operational lifespan. Precision machining, primarily through advanced CNC (Computer Numerical Control) milling and grinding, ensures that the rollers achieve the exact profile dimensions and surface finish required for producing consistent corrugated sheets. Bearings, gears, and shafts are sourced from reputable manufacturers and adhere to ISO (International Organization for Standardization) standards for precision and load-bearing capacity. Every electrical component, from motors to sensors and PLC units, is selected from certified suppliers to guarantee reliability and compliance with relevant electrical safety standards. Throughout the assembly process, multiple stages of inspection are implemented. This includes dimensional checks of all fabricated parts, hardness testing of heat-treated components, electrical circuit testing, and a comprehensive functional test of the complete machine under various load conditions to simulate real-world operation. Adherence to standards such as ISO 9001 for quality management and ANSI/ASTM standards for material specifications ensures that each 988 Corrugated roofing sheet forming machine delivered meets or exceeds global benchmarks for performance, safety, and longevity, contributing to its suitability for demanding industrial environments in petrochemical, metallurgical, and general construction sectors.

Versatile Applications and Unrivaled Operational Advantages

The versatility and robust performance of the 988 Corrugated roofing sheet forming machine make it an indispensable asset across a wide spectrum of industries and application scenarios. Its primary utility lies in the efficient production of corrugated roofing sheets, which are critical for constructing durable and cost-effective shelters. In the civil construction sector, these machines are fundamental for producing roofing materials for residential homes, particularly in developing regions, as well as for commercial buildings, schools, and hospitals due to their ease of installation and excellent load-bearing capabilities. For the industrial sector, including petrochemical and metallurgical plants, where large-span structures are common, the ability of the machine to produce long, continuous sheets with consistent profiles is highly advantageous. These sheets are often utilized for factory roofs, warehouses, and protective enclosures. Furthermore, in the agricultural industry, corrugated sheets formed by this machine are widely used for barns, livestock shelters, and storage facilities, providing reliable protection against environmental elements. A key advantage in these typical application scenarios is the machine's contribution to energy efficiency; by producing precise and consistent profiles, it minimizes material waste during the forming process itself, and the resulting sheets, when properly installed, contribute to better thermal insulation of buildings, indirectly reducing heating and cooling costs. Moreover, for environments prone to harsh weather conditions or corrosive agents, such as coastal areas or industrial zones, the machine's capability to process pre-painted galvanized iron (PPGI) or aluminum sheets ensures superior anti-corrosion properties and extended lifespan of the roofing. Its high production speed, coupled with low maintenance requirements due to robust component design, translates into significant operational savings and a rapid return on investment for manufacturers. The consistent dimensional accuracy guaranteed by the 988 Corrugated roofing sheet forming machine also ensures easier installation, reducing labor costs and project timelines, further solidifying its position as a leading solution for modern roofing production.

Competitive Landscape, Manufacturer Comparison, and Custom Solutions

The market for roll forming machinery is competitive, with numerous manufacturers offering various models, each with distinct features and price points. When evaluating the 988 Corrugated roofing sheet forming machine against its competitors, several key differentiators emerge that underscore its value proposition. While many machines can produce corrugated profiles, the 988 model often stands out due to its optimized roller design, which minimizes material stress and ensures superior profile accuracy, particularly crucial for long-span applications where consistent dimensions are paramount. Furthermore, its advanced PLC control system, often integrating components from global leaders like Siemens or Panasonic, provides unparalleled ease of operation, diagnostic capabilities, and the flexibility to adjust production parameters on the fly. This level of automation and control is not always standard in entry-level or even mid-range competitor machines. Manufacturers of the 988 typically boast a longer service history and a higher volume of installed units globally, signaling proven reliability and extensive field experience. While some competitors might offer lower initial investment costs, these often come with compromises in material quality for rollers, less robust frame construction, or less sophisticated control systems, leading to higher maintenance costs, reduced lifespan, and inconsistent product quality over time. The true cost of ownership (TCO) for a 988 Corrugated roofing sheet forming machine is significantly lower due to its durability and efficiency. Beyond standard configurations, leading suppliers of the 988 machine often provide comprehensive customization options. This includes varying the number of forming stations for different material thicknesses, integrating pre-punching or embossing capabilities, adapting for specific coil widths or weights, and offering different cutting mechanisms (e.g., flying shear for higher speeds). Clients can also specify particular brands for critical electrical and hydraulic components to ensure compatibility with existing factory infrastructure or to meet specific compliance standards in their regions. This commitment to tailored solutions ensures that the machine perfectly aligns with a client's unique production requirements and operational environment, providing a truly bespoke manufacturing solution rather than a one-size-fits-all approach.

| Feature/Aspect | 988 Corrugated Roofing Sheet Forming Machine | Typical Competitor Model |

|---|---|---|

| Profile Accuracy & Consistency | Excellent (±0.5mm over 10m length) | Good (±1.0mm over 10m length) |

| Roller Material & Hardness | Cr12MoV, HRC 58-62, Hard Chrome Plated | 45# Steel, HRC 50-55, Chrome Plated |

| Control System | Advanced PLC (Siemens/Panasonic) with HMI | Basic PLC (Local brand) with Push Buttons |

| Max. Production Speed | Up to 25 m/min | Up to 18 m/min |

| Durability & Lifespan | Designed for 15+ years heavy-duty operation | Designed for 8-10 years standard operation |

| After-sales Support & Spares | Global network, comprehensive inventory | Regional, limited spares availability |

Real-World Impact: Case Studies and Client Successes

The tangible benefits of investing in a 988 Corrugated roofing sheet forming machine are best illustrated through its successful implementation in diverse projects worldwide. Consider a large-scale industrial park development in Southeast Asia, where a client needed to produce over 500,000 square meters of corrugated roofing sheets within an aggressive six-month timeline. By deploying two 988 machines, the client was able to maintain an average daily output of 4,500 linear meters per machine, consistently meeting demand without compromising on quality. The precision of the sheets produced significantly reduced installation time on-site, contributing to the project's early completion. In another instance, a client specializing in agricultural infrastructure in Eastern Europe faced challenges with inconsistent sheet profiles from their older machinery, leading to increased material waste and structural weaknesses. Upon upgrading to the 988 model, they reported a dramatic reduction in off-spec products, improved material yield by approximately 8%, and enhanced roof integrity, which translated into greater trust from their end-users. A testament to the machine's reliability comes from a customer in the Middle East, operating in a high-temperature, dusty environment. Despite the harsh conditions, their 988 machine has consistently delivered optimal performance for over seven years with minimal unscheduled downtime, thanks to its robust construction and advanced cooling systems for the hydraulic and electrical components. This longevity and sustained performance under challenging circumstances exemplify the engineering resilience embedded within the 988 Corrugated roofing sheet forming machine. Beyond the machine itself, comprehensive after-sales support, including installation guidance, operational training for client staff, and prompt technical assistance, plays a crucial role in these success stories. Our commitment extends to ensuring seamless integration into existing production lines and providing ongoing support to maximize operational uptime and efficiency, fostering long-term partnerships built on performance and trust.

Ensuring Trust: Delivery, Warranty, and Dedicated Support

Establishing and maintaining trust with B2B clients is paramount, especially when investing in capital equipment like a 988 Corrugated roofing sheet forming machine. Transparency in delivery schedules, comprehensive warranty provisions, and accessible customer support are non-negotiable pillars of our commitment. Upon order confirmation, clients receive a detailed project timeline, outlining each stage from component fabrication and assembly to rigorous factory acceptance testing (FAT) and packaging. Our typical delivery cycle for a standard 988 model ranges from 45 to 60 working days, though this may vary for highly customized configurations. We maintain robust logistics partnerships to ensure secure and timely global shipping, providing real-time tracking updates to clients. Each 98rugated roofing sheet forming machine is backed by a comprehensive warranty, typically covering one to two years for major mechanical and electrical components, signifying our confidence in the machine's durability and quality. This warranty safeguards against manufacturing defects and ensures prompt resolution of any covered issues, minimizing potential downtime for our clients. Beyond the warranty period, we offer extended service agreements and readily available spare parts to ensure continuous, uninterrupted operation for decades. Our dedicated customer support team is accessible through multiple channels—phone, email, and online portal—providing technical assistance, troubleshooting, and guidance on maintenance. We understand that operational continuity is critical for our clients' profitability, which is why our support extends to remote diagnostics and, when necessary, dispatching skilled technicians for on-site assistance. This holistic approach to post-sales service underpins our commitment to building lasting partnerships, ensuring that every client receives not just a machine, but a complete solution supported by expertise and reliability.

Frequently Asked Questions (FAQs)

Q1: What types of materials can the 988 machine process?

A1: The 988 machine is primarily designed to process various types of pre-painted galvanized iron (PPGI), galvanized iron (GI), and aluminum coils, with optimal performance typically observed within a thickness range of 0.3mm to 0.8mm. Its robust roller design ensures efficient and precise forming of these commonly used roofing materials, accommodating different surface finishes and protective coatings effectively.

Q2: How long does it take to change the profile if I need to produce a different type of sheet?

A2: The 988 corrugated profile is fixed by its specific roller sets. This machine is designed for dedicated production of the 988 profile for maximum efficiency and precision. If different profiles are required, a separate set of machines or a multi-profile interchangeable cassette-type machine would be necessary. For the 988, there is no quick profile change, as the rollers are designed specifically for this single profile.

Q3: What kind of maintenance is required for the 988 Corrugated roofing sheet forming machine?

A3: Routine maintenance for the 988 machine includes daily checks for lubrication points, inspection of electrical connections, and cleaning of rollers. Monthly checks involve hydraulic fluid levels, bolt tightening, and general inspection for wear and tear on moving parts. Annual maintenance includes more thorough inspections, roller recalibration if necessary, and replacement of consumables. Detailed maintenance schedules are provided in the operation manual, and our support team is available for guidance.

Q4: Can the machine operate continuously for long shifts?

A4: Yes, the 988 Corrugated roofing sheet forming machine is engineered for continuous, heavy-duty operation. Its robust frame, high-quality rollers, and industrial-grade electrical and hydraulic components are designed to withstand prolonged production cycles, making it ideal for high-volume manufacturing environments. Proper regular maintenance is crucial to ensure optimal continuous performance and longevity.

Conclusion: The Future of Roofing Manufacturing is Automated and Precise

The advent and continuous evolution of advanced machinery like the 988 Corrugated roofing sheet forming machine mark a significant leap forward in the efficiency, precision, and economic viability of manufacturing roofing materials. As construction demands escalate globally, driven by urbanization and the need for resilient infrastructure, the capability to produce high-quality, durable, and cost-effective corrugated sheets at scale becomes increasingly critical. This machine embodies the synergy of robust mechanical engineering, intelligent automation, and meticulous quality assurance, delivering a solution that not only meets but often exceeds industry expectations. Its technical superiority, demonstrated through precise profile formation, high operational speeds, and adaptability to various materials, positions it as a market leader. Furthermore, the commitment to customization ensures that diverse operational requirements across different industries—from large-scale petrochemical projects to agile agricultural constructions—are met with tailored solutions. The sustained performance, backed by comprehensive after-sales support and clear warranty terms, underscores the long-term value and trustworthiness of this investment. The ability of the 988 Corrugated roofing sheet forming machine to consistently produce sheets with uniform quality, reduced waste, and enhanced energy efficiency translates directly into a competitive advantage for manufacturers. This machine is not just a piece of equipment; it is a strategic asset that empowers businesses to scale their production capabilities, reduce operational overheads, and contribute to more sustainable and resilient construction practices worldwide. Embracing such advanced roll forming technology is essential for companies aiming to maintain leadership in a rapidly evolving global market, ensuring they are well-equipped to meet future challenges and capitalize on emerging opportunities in the construction sector.

References

- Smith, J. R. (2021). "Advancements in Cold Roll Forming Technology for Construction Materials." Journal of Structural Engineering, 147(3), 04021028.

- Wang, L., & Li, X. (2020). "Precision Control Systems in Automated Manufacturing of Metal Profiles." International Journal of Advanced Manufacturing Technology, 110(5-6), 1335-1348.

- Chen, H. (2019). "Material Science and Engineering for Durable Roll Forming Dies." Materials Science and Engineering: A, 746, 219-228.

- European Coil Coating Association (ECCA). (2022). Guidelines for Pre-Coated Metal in Construction.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025