hat channel roll forming machine factory

The Evolution of Hat Channel Roll Forming Machines A Comprehensive Overview

In the realm of modern manufacturing, roll forming technology has emerged as a crucial method for producing complex metal shapes with high precision and efficiency. Among these innovations, the hat channel roll forming machine stands out, particularly for its role in fabricating hat channels—essential components used in various construction and industrial applications. This article explores the significance, functionality, and advancements in hat channel roll forming machines, highlighting their importance in today’s manufacturing landscape.

Hat channels are C-shaped metal profiles that feature a top flange, two vertical sides, and a bottom flange. Their unique shape provides exceptional structural support, making them ideal for use in frameworks, ceilings, and mechanical support systems. The demand for these profiles has surged in recent years, as architects and builders increasingly seek lightweight yet robust materials in construction.

The Technology Behind Hat Channel Roll Forming Machines

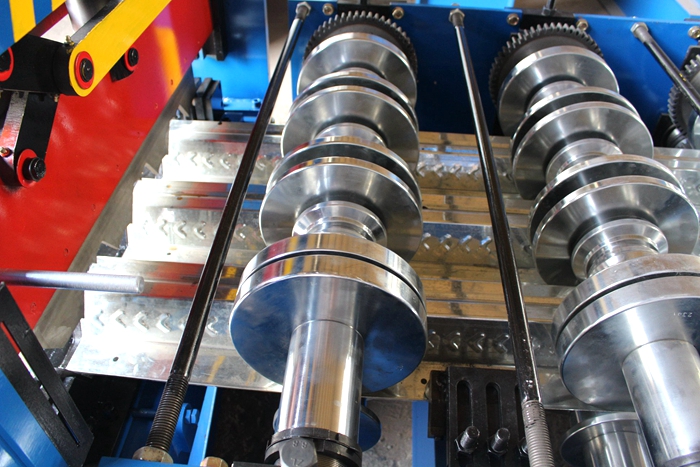

At the heart of hat channel production is the roll forming machine, which utilizes a series of rollers arranged in a specific sequence to gradually shape flat metal strips into the desired cross-sectional profile. The process begins with feeding a flat metal sheet into the machine, which then passes through a series of rollers that incrementally bend and shape the metal into a hat channel profile. The precision of this method ensures uniformity and accuracy, which are critical factors in construction and fabrication.

A typical hat channel roll forming machine consists of various components, including - Feed Mechanism This part controls the speed and alignment of the metal strip as it enters the machine. - Rollers The main feature of the machine, these rollers are designed to incrementally bend the steel into the final shape. The number and configuration of rollers can vary depending on the specific design requirements of the hat channel. - Cutting Mechanism Once the desired length of hat channel is formed, the cutting mechanism ensures clean, precise ends for each piece. - Control System Modern roll forming machines are often equipped with advanced computer numerical control (CNC) systems, allowing for automation and precision in forming. This ensures that production can be scaled up efficiently while maintaining high quality.

Advantages of Hat Channel Roll Forming Machines

hat channel roll forming machine factory

The use of hat channel roll forming machines brings numerous advantages to the manufacturing process. Firstly, it allows for high-speed production with minimal waste. The continuous operation of the rollers ensures that metal is used efficiently, significantly reducing scrap material. Additionally, the automation of the forming process guarantees consistent quality and dimensional accuracy across large production runs.

Furthermore, the versatility of these machines allows manufacturers to create customized hat channel profiles tailored to specific project requirements. With adjustable settings and interchangeable roller dies, fabricators can easily switch between different designs without extensive downtime.

Recent Advancements and Innovations

The field of hat channel roll forming technology has evolved significantly in recent years, driven by the integration of smart manufacturing practices. Companies are increasingly adopting Industry 4.0 principles, incorporating IoT (Internet of Things) devices and real-time monitoring systems into their machinery. This connectivity provides manufacturers with valuable insights, enabling predictive maintenance, enhanced production efficiency, and improved product quality.

Moreover, advancements in material science have introduced new alloys and steel grades that enhance the performance of hat channels, such as increased strength-to-weight ratios and better corrosion resistance. This further expands the applications of hat channels in various industries, including construction, automotive, and aerospace.

Conclusion

The hat channel roll forming machine is more than just a piece of machinery; it is a vital component in the modern manufacturing ecosystem. With its ability to produce high-quality, customized profiles efficiently, the roll forming technology has transformed how industries approach structural components. As manufacturers continue to innovate and adapt to changing market demands, the role of hat channel roll forming machines will undoubtedly grow, paving the way for new possibilities in construction and beyond.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025