Feb . 03, 2025 01:35

Back to list

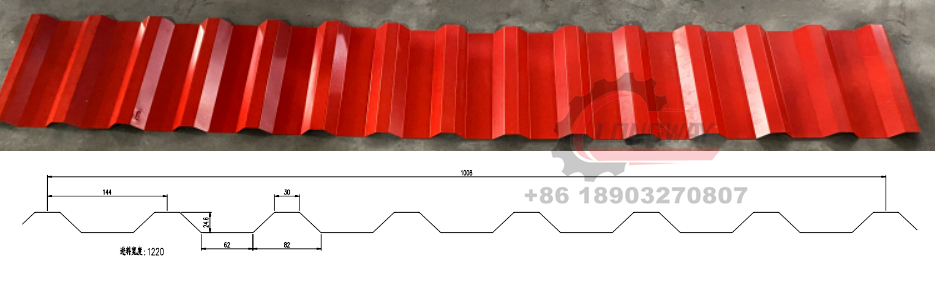

hat channel roll forming machine

The hat channel roll forming machine is an essential tool in the construction and manufacturing industries, bringing efficiency and precision to the production of hat channels, a vital component used for installing drywall, ceilings, and other structural applications. This article delves into the sophisticated nature of hat channel roll forming machines, exploring their design, benefits, and the transformative impact they have on modern construction practices.

Projects ranging from residential buildings to large-scale commercial developments benefit from hat channels produced by roll forming machines, as they provide a lightweight yet robust framework that simplifies installation. Moreover, these channels' uniformity aids in reducing material waste and increasing the efficiency of construction crews. Trust and Authority in Manufacturing When sourcing a hat channel roll forming machine, selecting a manufacturer with established authority in the industry is crucial. Companies with a strong track record demonstrate trustworthiness through their commitment to quality control, customer support, and innovation. They offer machines crafted from high-grade materials, ensuring longevity and excellent performance even under the most demanding conditions. Expert reviews and case studies often highlight the real-world applications and customer satisfaction associated with these machines. Reliable manufacturers provide comprehensive training and maintenance programs to ensure end-users can maximize the machine's potential, further cementing their status as leaders in roll forming technology. Enhancing the Experience Through Innovation The latest advancements in hat channel roll forming machines focus on user experience enhancements. Interactive user interfaces, customizable settings, and easy-to-follow operational protocols are design aspects that empower operators to utilize these machines effectively. By reducing complexity and incorporating smart diagnostic tools, manufacturers are making it easier for operators to perform routine checks and troubleshoot potential issues. Looking forward, the integration of IoT and smart technologies seems poised to revolutionize these machines further. Predictive maintenance, remote monitoring, and even machine-to-machine communication are on the horizon, promising to elevate efficiency and reduce downtime. In conclusion, the hat channel roll forming machine is a testament to the power of engineering to provide reliable, efficient solutions for the construction industry. Its role in transforming metal coils into precise components ensures that modern building projects can achieve new heights of quality and performance. By choosing a reputable machine, manufacturers and contractors alike can harness expertise, trust, and innovation to drive success in their respective fields. As construction demands evolve, so too will the sophistication of these machines, continuing to set benchmarks for quality and efficiency in metal forming industries.

Projects ranging from residential buildings to large-scale commercial developments benefit from hat channels produced by roll forming machines, as they provide a lightweight yet robust framework that simplifies installation. Moreover, these channels' uniformity aids in reducing material waste and increasing the efficiency of construction crews. Trust and Authority in Manufacturing When sourcing a hat channel roll forming machine, selecting a manufacturer with established authority in the industry is crucial. Companies with a strong track record demonstrate trustworthiness through their commitment to quality control, customer support, and innovation. They offer machines crafted from high-grade materials, ensuring longevity and excellent performance even under the most demanding conditions. Expert reviews and case studies often highlight the real-world applications and customer satisfaction associated with these machines. Reliable manufacturers provide comprehensive training and maintenance programs to ensure end-users can maximize the machine's potential, further cementing their status as leaders in roll forming technology. Enhancing the Experience Through Innovation The latest advancements in hat channel roll forming machines focus on user experience enhancements. Interactive user interfaces, customizable settings, and easy-to-follow operational protocols are design aspects that empower operators to utilize these machines effectively. By reducing complexity and incorporating smart diagnostic tools, manufacturers are making it easier for operators to perform routine checks and troubleshoot potential issues. Looking forward, the integration of IoT and smart technologies seems poised to revolutionize these machines further. Predictive maintenance, remote monitoring, and even machine-to-machine communication are on the horizon, promising to elevate efficiency and reduce downtime. In conclusion, the hat channel roll forming machine is a testament to the power of engineering to provide reliable, efficient solutions for the construction industry. Its role in transforming metal coils into precise components ensures that modern building projects can achieve new heights of quality and performance. By choosing a reputable machine, manufacturers and contractors alike can harness expertise, trust, and innovation to drive success in their respective fields. As construction demands evolve, so too will the sophistication of these machines, continuing to set benchmarks for quality and efficiency in metal forming industries.

Next:

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products