gypsum channel making machine factories

Gypsum Channel Making Machine Factories Innovating the Construction Industry

The construction industry has seen considerable advancements in technology over recent years, and one of the most significant developments is the introduction of gypsum channel making machines. These machines are pivotal in producing gypsum channels, which are widely used for creating partitions, ceilings, and other architectural features in buildings. With the growing demand for prefabricated building materials, factories that manufacture gypsum channel making machines are becoming increasingly essential.

The Importance of Gypsum Channels

Gypsum is favored in construction for its versatility, fire resistance, and sound insulation properties. Gypsum channels, specifically, serve as structural components that support the installation of gypsum boards. They facilitate the creation of various architectural designs while ensuring durability and stability. As the need for lightweight and environmentally friendly building materials rises, gypsum channels have emerged as an optimal choice for modern construction.

The Role of Gypsum Channel Making Machines

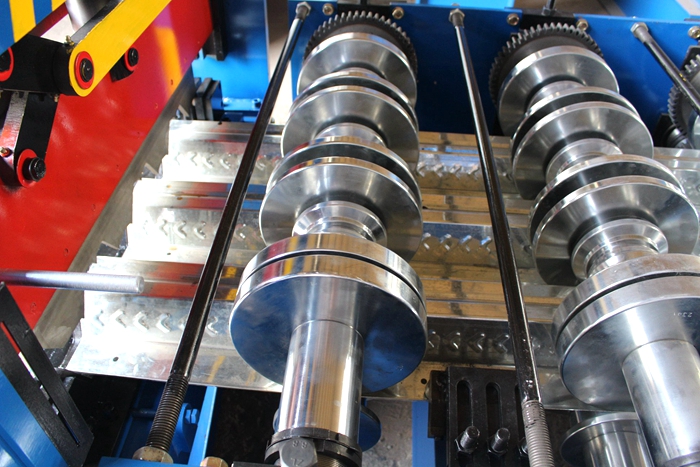

Gypsum channel making machines automate the production process of gypsum channels, enabling factories to meet the soaring demand quickly and efficiently. These machines utilize advanced technology to ensure precision in cutting, molding, and forming, which results in high-quality products with consistent dimensions. The automation of the production process leads to increased productivity, reduced labor costs, and minimized material wastage.

Modern gypsum channel making machines come equipped with features such as computer numerical control (CNC), which allows for customizable manufacturing according to specific project requirements. Additionally, these machines can be adapted to produce various sizes and shapes of channels, providing flexibility for manufacturers to cater to diverse construction needs.

Factors Influencing the Growth of Gypsum Channel Making Machine Factories

gypsum channel making machine factories

Several factors contribute to the growth of gypsum channel making machine factories. First, the global construction industry is on a robust growth trajectory, driven by urbanization and increasing infrastructure projects worldwide. As cities expand, the demand for efficient building materials continues to rise, propelling the need for gypsum channels produced by specialized machines.

Second, the trend towards sustainable building practices is gaining momentum. Gypsum is a sustainable material that can be recycled, making it an attractive option for eco-friendly construction. Gypsum channel making machine factories that focus on sustainable manufacturing processes can appeal to environmentally conscious builders and developers, thus enhancing their market presence.

Finally, technological advancements in manufacturing processes, such as the incorporation of automation and robotics, are driving the efficiency and quality of gypsum channel production. Factories that invest in modern machinery and innovative technologies will likely lead the industry, setting benchmarks for quality and performance.

Challenges Facing Gypsum Channel Making Machine Factories

Despite the substantial opportunities in this sector, factories face several challenges. One of the primary obstacles is the fluctuating price of raw materials, which can affect production costs and profit margins. Additionally, with the rise of competition, factories must continually innovate and enhance their machines to stay ahead in the market.

Moreover, there is a need for skilled labor capable of operating advanced machinery and maintaining production quality. Factories must invest in training programs to ensure their workforce is equipped with the necessary skills to operate sophisticated equipment effectively.

Conclusion

Gypsum channel making machine factories play a crucial role in the evolution of the construction industry. They not only enhance the efficiency of gypsum channel production but also contribute to the overall sustainability of building practices. As demand for gypsum channels continues to rise in tandem with infrastructure development and environmental considerations, these factories are poised for growth, promising a bright future for the manufacturing of construction materials. The integration of advanced technologies, combined with a focus on sustainability, will undoubtedly shape the next phase of innovation in this essential industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025