gutter rolling machine factory

The Gutter Rolling Machine Factory Revolutionizing Gutter Production

In the modern construction and manufacturing industries, efficiency and quality are paramount. One of the unsung heroes behind these industries is the gutter rolling machine, which has become essential for producing high-quality gutters quickly and efficiently. This article explores the functioning, importance, and advantages of gutter rolling machines, focusing on a factory dedicated to their manufacturing.

Understanding Gutter Rolling Machines

Gutter rolling machines are specialized equipment designed to create seamless gutters from metal sheets. These machines perform a series of intricate processes that include cutting, rolling, and forming materials into the desired shapes. The production of seamless gutters is a significant advancement over traditional methods, which often involved multiple sections joined together. With playful precision, gutter rolling machines make streamlined, attractive, and durable gutters that enhance both functionality and aesthetics in residential and commercial buildings.

The Gutter Rolling Machine Factory

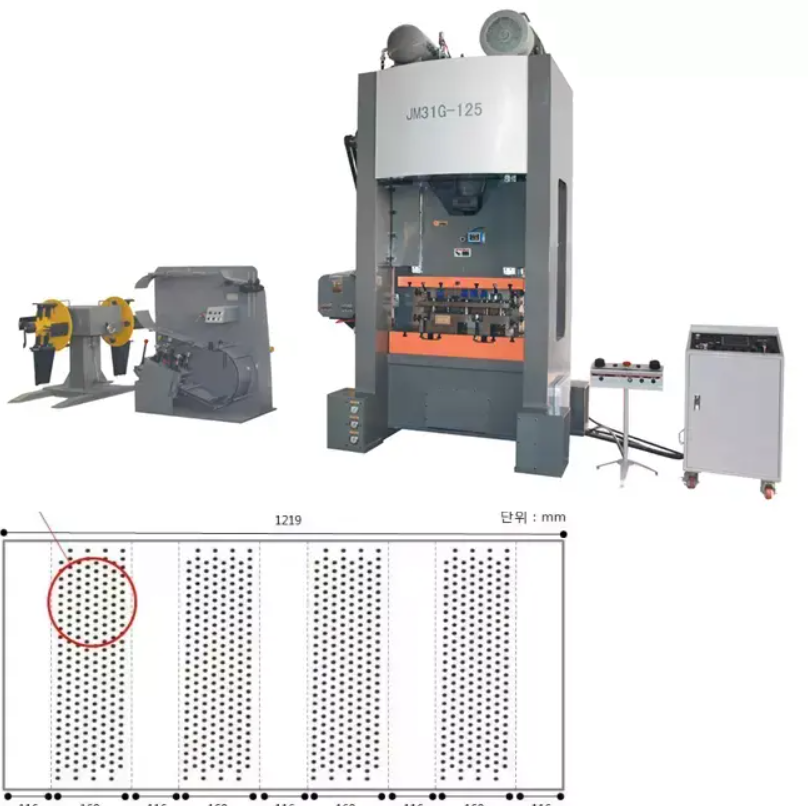

At the heart of this innovation is the gutter rolling machine factory, where skilled engineers and technicians work together to design, manufacture, and assemble these sophisticated machines. The factory employs cutting-edge technology, ensuring each machine produced is reliable, efficient, and tailored for various materials, including aluminum, copper, and galvanized steel. From the initial concept to the final assembly, every phase of production is executed with precision and quality control measures to meet the highest standards.

One of the key highlights of the factory is its commitment to research and development. Continuous innovation is important in the construction industry, where new materials and methods frequently emerge. By investing in R&D, the factory stays ahead of market trends, allowing it to introduce models that integrate advanced features such as automated controls, digital displays, and enhanced safety measures.

The Process of Manufacturing Gutter Rolling Machines

The manufacturing process of gutter rolling machines involves several stages. Initially, high-quality raw materials are sourced. Next, these materials undergo cutting and bending to create the machine's components. After this, precision machining ensures that all parts fit together seamlessly.

gutter rolling machine factory

Once components are ready, assembly begins. Skilled technicians meticulously put together the machines, paying special attention to alignment and functionality. After assembly, each machine undergoes rigorous testing to verify its performance and durability under various conditions. This extensive quality assurance process ensures that the final products meet or exceed industry standards.

Advantages of Using Gutter Rolling Machines

The advantages of utilizing gutter rolling machines in production are numerous. Firstly, they significantly reduce labor costs and time in manufacturing gutters. Because these machines can produce long lengths of seamless gutters efficiently, fewer joints are required, minimizing the risk of leaks and ensuring longevity.

Secondly, the precision offered by gutter rolling machines provides a better fit for structures, leading to enhanced aesthetic appeal and functionality. Homeowners and contractors can choose from various styles and finishes, enabling custom solutions that meet specific design criteria.

Furthermore, seamless gutters produced through these machines can resist corrosion better and require less maintenance compared to traditional gutters. The reduction in joints means fewer potential points for water accumulation and mold growth, improving the overall durability of the installation.

Conclusion

The gutter rolling machine factory plays a vital role in modern construction, providing technology that dramatically enhances the production of gutters. With a focus on quality, innovation, and efficiency, these factories are not just manufacturers but also pioneers in creating solutions that meet the evolving demands of the industry.

As building designs become more complex and sustainability continues to be a priority, the importance of high-quality, seamless gutter solutions will only grow. Investing in gutter rolling machines and their manufacturing processes represents a forward-thinking approach to construction that aligns with the future of building practices. In this rapidly changing landscape, the gutter rolling machine factory is more than just a factory—it's a crucial player in the quest for architectural excellence.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025