gutter roll forming machine company

Gutter Roll Forming Machine Revolutionizing the Gutter Manufacturing Industry

In the modern construction landscape, the need for efficient and durable building materials is paramount. Among these materials, gutters play a crucial role in water drainage. The proper management of water flow can prevent significant structural damage and enhance the longevity of a building. One of the most innovative solutions for manufacturing gutters is the gutter roll forming machine. This technology has transformed how gutters are produced, offering businesses the ability to create high-quality products with increased efficiency.

Understanding Gutter Roll Forming Machines

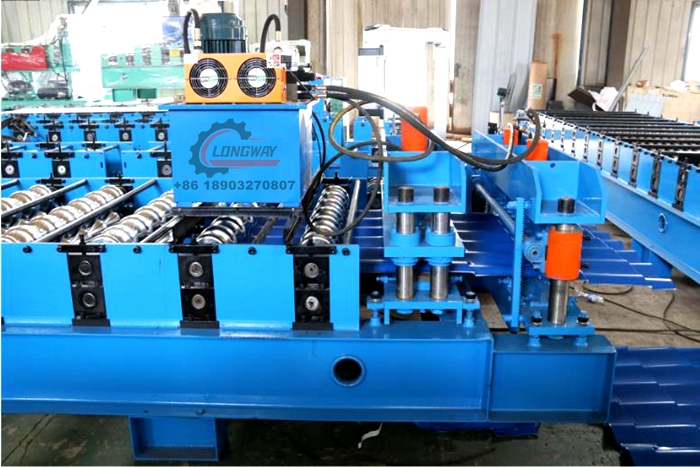

A gutter roll forming machine is a specialized piece of equipment designed to produce seamless gutters from metal sheets. The machine operates by feeding metal coils through a series of rollers that shape the metal into the desired profile. The process is continuous, allowing for the production of long lengths of gutters without the need for welding or joints, which significantly reduces the risk of leaks.

The design of a gutter roll forming machine typically features an adjustable system that allows manufacturers to switch between various gutter profiles and sizes. This versatility ensures that businesses can cater to different customer needs and preferences while minimizing downtime associated with changeovers.

Key Features and Advantages

1. High Efficiency One of the primary benefits of using a gutter roll forming machine is its high production rate. The automated nature of the machine means that it can produce gutters continuously, significantly increasing output compared to traditional manufacturing methods.

2. Precision and Consistency The roll forming process ensures that each gutter produced meets strict accuracy standards. The precise engineering of the rollers allows for uniformity in shape and size, which is crucial for proper installation and functionality.

3. Material Versatility Gutter roll forming machines can work with a variety of materials, including galvanized steel, aluminum, and copper. This flexibility allows manufacturers to offer a broader range of products to their customers, meeting differing needs in terms of aesthetics, durability, and cost.

4. Cost-Effectiveness While the initial investment in a gutter roll forming machine may be significant, the long-term savings are substantial. The reduction in labor costs and the ability to produce high-quality materials without waste make this machinery a worthwhile investment for many manufacturing businesses.

gutter roll forming machine company

5. Minimal Waste The roll forming process generates minimal scrap material, making it a more sustainable option for gutter production. This not only benefits the environment but also contributes to cost savings for manufacturers.

Applications of Gutter Roll Forming Machines

The gutters produced by roll forming machines serve a wide range of applications. They are essential for residential buildings, commercial structures, and industrial facilities. Beyond traditional uses, custom profiles can be produced for specialized applications, such as decorative guttering for historical buildings or unique architectural designs.

Moreover, the construction industry’s growing focus on sustainability has driven demand for high-quality, durable gutters. Roll-formed gutters can be designed to fit eco-friendly buildings, providing effective drainage solutions while maintaining aesthetic appeal.

Future Trends

As technology continues to advance, gutter roll forming machines are likely to incorporate IoT capabilities, providing manufacturers with real-time data on production efficiency, maintenance needs, and product quality. Automation and robotics may further enhance production capabilities, leading to even higher efficiency rates.

In addition, the demand for customizable and environmentally friendly products is expected to grow, pushing manufacturers to innovate and adapt their offerings. Gutter roll forming machines are well-positioned to meet these evolving needs, enabling businesses to remain competitive in a dynamic market.

Conclusion

The emergence of gutter roll forming machines marks a significant advancement in the manufacturing of gutters. With their ability to produce high-quality, customizable products efficiently, these machines are redefining the standards of the industry. As construction requirements continue to evolve, gutter roll forming machines will undoubtedly play an integral role in shaping the future of building materials, ensuring that structures are both functional and visually appealing. Investing in this technology not only enhances production capabilities but also positions businesses for long-term success in a competitive marketplace.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025