gutter bending machine for sale

The Rise of Gutter Bending Machines Efficiency Meets Innovation

The construction industry has constantly evolved, driven by the need for efficiency, adaptability, and precision. Among the various tools that have transformed workflow and operational productivity, gutter bending machines stand out as essential equipment for many contractors and builders. As demand for custom seamless gutters rises, the market for gutter bending machines for sale has expanded, leading to advancements in both functionality and usability.

Understanding Gutter Bending Machines

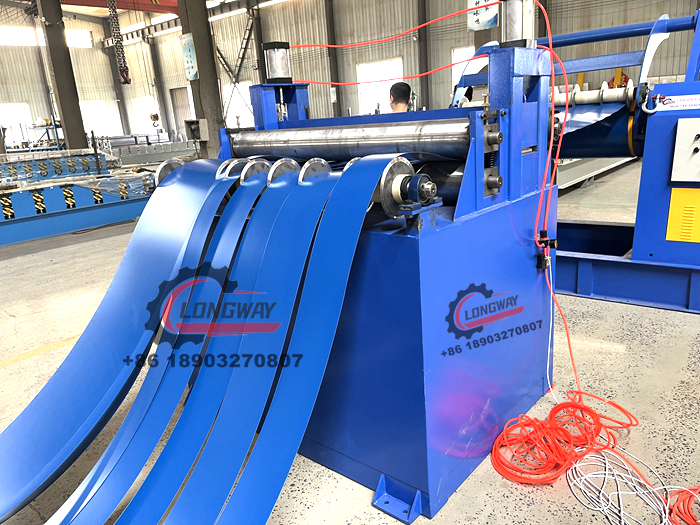

Gutter bending machines are specialized tools designed to create custom gutters from metal sheets. Their primary function is to bend and shape materials, often aluminum or galvanized steel, into various profiles that fit the specific requirements of a project. Unlike traditional methods that may rely heavily on manual labor, these machines automate much of the bending process, greatly enhancing efficiency and reducing labor costs.

These machines come in various types, including manual, semi-automatic, and fully automatic versions. Manual machines require hands-on operation, while semi-automatic and fully automatic systems can produce consistent results with minimal operator intervention. The choice of machine often depends on the scale of the operation and the specific requirements of the projects handled.

Benefits of Using Gutter Bending Machines

1. Increased Efficiency One of the most significant advantages of using gutter bending machines is the increase in productivity. These machines can often bend and cut gutters with precision in a fraction of the time it would take to do manually, enabling contractors to complete more jobs in a shorter timeframe.

2. Consistent Quality The automated nature of gutter bending machines ensures that each piece produced is identical, meeting stringent industry standards. This consistency reduces the risk of errors that can occur with manual bending, which can lead to waste and additional costs.

3. Customization Today’s machines allow for a high level of customization. Operators can adjust the machines to create unique shapes and sizes, catering to the specific needs of clients and a variety of architectural styles. This flexibility is a crucial selling point for contractors in a competitive marketplace.

4. Cost-Effectiveness Although the initial investment in a gutter bending machine might be significant, the long-term savings in labor costs and material waste often outweigh the upfront costs. As many contractors have discovered, investing in such technology can lead to better profit margins.

gutter bending machine for sale

5. Ease of Use Modern gutter bending machines are designed with user-friendly controls and interfaces, allowing operators with minimal training to become proficient quickly. This feature is especially beneficial in today’s labor market, where skilled tradespeople may be in short supply.

Choosing the Right Gutter Bending Machine

When considering the purchase of a gutter bending machine, several factors should be taken into account

- Material Compatibility Ensure that the machine can handle the types of materials commonly used in gutter production—typically aluminum or steel.

- Size and Portability Depending on your workspace, consider the machine's size and whether it can be easily transported to job sites.

- Production Capacity Assess how many jobs you can realistically handle with the machine. Higher production capacities may justify higher initial investments.

- Features and Technology Look for machines equipped with advanced technology, such as digital controls, programmable settings, and safety features.

- Manufacturer Reputation and Support Research manufacturers and their reputation for quality and customer service. Good support can be invaluable for maintenance and repairs.

Conclusion

In conclusion, gutter bending machines represent a significant advancement in the construction industry, marrying efficiency with precision. As the demand for custom gutters continues to grow, investing in such technology can provide contractors with the edge they need to thrive in a competitive market. For those interested in gutter bending machines for sale, careful consideration of features, costs, and capabilities will ensure that the selected machine meets both current and future project demands. With the right equipment, contractors can not only enhance their productivity but also improve their bottom line.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025