guardrail roll forming machine suppliers manufacturers

Exploring Guardrail Roll Forming Machine Suppliers and Manufacturers

In the construction and transportation industries, safety is of paramount importance. One key component in ensuring this safety are guardrails, which protect both vehicles and pedestrians from potential hazards. The manufacturing of these essential safety features relies heavily on specialized equipment, particularly guardrail roll forming machines.

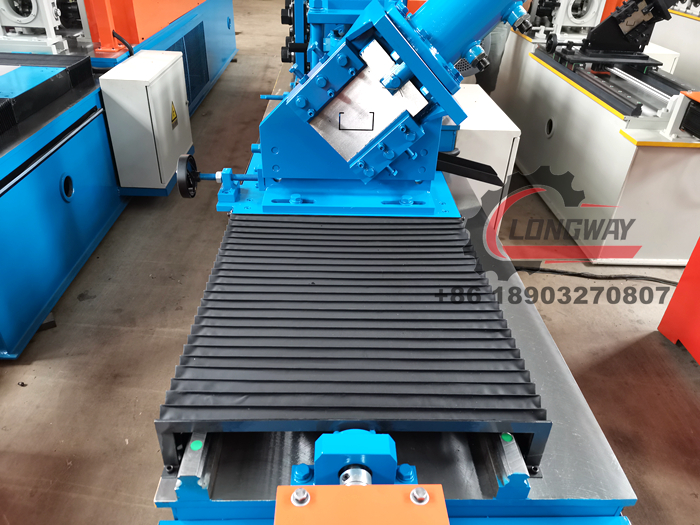

Guardrail roll forming machines are specialized pieces of machinery designed to produce guardrails efficiently and with precision. These machines use a roll forming process, wherein metal sheets are fed through a series of rollers that shape them into the desired profile. The output is a robust, durable guardrail that meets stringent safety standards.

When seeking suppliers and manufacturers of guardrail roll forming machines, there are several factors to consider. First, reliability and experience are crucial. Established manufacturers often have a proven track record of producing high-quality machines that stand the test of time. They also typically offer comprehensive customer support, helping clients with installation, maintenance, and troubleshooting.

Another key consideration is the technology used in the machinery. Advanced roll forming machines utilize the latest technologies, ensuring efficiency and precision in the production process. Features such as programmable control systems, automatic adjustments, and high-speed operation can greatly enhance productivity, making it essential to choose suppliers who invest in modern technology.

guardrail roll forming machine suppliers manufacturers

Furthermore, the material used in the construction of these machines plays a vital role in their overall performance. High-quality steel components can significantly enhance durability and reduce maintenance costs over time. Therefore, it is advisable to partner with manufacturers who prioritize the quality of their materials.

Customization options are also an important factor. Different projects may require specific guardrail designs or dimensions; hence, working with suppliers that offer tailor-made solutions can significantly benefit clients. This flexibility allows for the production of guardrails that meet varied aesthetic and functional requirements.

Lastly, pricing and warranty options should not be overlooked. While it is tempting to choose the cheapest option available, the long-term costs associated with lower-quality machines can outweigh initial savings. Reliable suppliers typically provide warranties that reflect their confidence in the machine's longevity and performance.

In conclusion, guardrail roll forming machines are vital for the safe production of guardrails, and selecting the right supplier or manufacturer is crucial. By prioritizing experience, technology, quality materials, customization, and fair pricing, businesses can ensure they invest in equipment that not only meets their needs but exceeds industry standards. When sourcing these machines, taking the time to do thorough research will undoubtedly pay off in producing safe and reliable guardrails.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025