guardrail roll forming machine manufacturers company

The Emergence of Guardrail Roll Forming Machine Manufacturers

In the modern world, the demand for safety infrastructure has surged, leading to a significant rise in the production of guardrails. These essential road safety features play a crucial role in minimizing accidents by providing a barrier between vehicles and obstacles. To meet this growing demand, guardrail roll forming machine manufacturers have emerged as pivotal players in the field of construction and manufacturing.

The Importance of Guardrails

Guardrails are designed to prevent vehicles from veering off the road, especially in hazardous areas such as curves, bridges, and raised medians. Statistically, regions that employ guardrails effectively experience fewer accidents and lower severity in collision incidents. This vital role of guardrails has propelled the need for reliable and efficient manufacturing processes to produce these components at scale.

Role of Roll Forming Machinery

The production of guardrails has traditionally involved various manufacturing processes, but roll forming has become increasingly popular due to its efficiency and capability to create complex shapes with precision. Roll forming is a continuous bending operation in which a long strip of metal is gradually shaped into a desired cross-section. This method allows for high-volume production, reducing both time and labor costs while ensuring uniformity in the finished product.

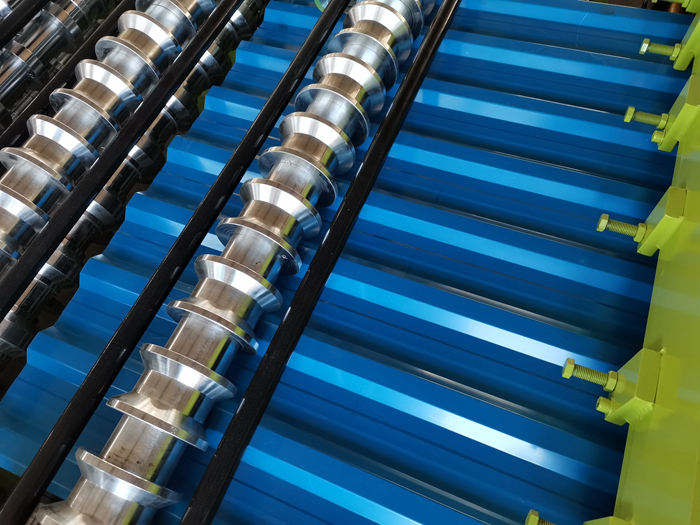

Guardrail roll forming machines are specialized equipment designed specifically for this purpose. These machines can handle various materials, including steel and aluminum, providing manufacturers with flexibility in their production processes. The precision offered by these machines ensures that all components meet stringent safety regulations and quality standards.

Key Features of Guardrail Roll Forming Machines

Modern guardrail roll forming machines boast several innovative features that enhance their efficiency and output.

1. High Speed and Efficiency Advanced roll forming machines operate at high speeds, achieving significant output levels while maintaining consistent quality. This efficiency is vital in meeting market demands without sacrificing performance.

2. Customization Options Manufacturers can customize roll forming machines to produce different guardrail designs. This flexibility allows them to cater to diverse client needs, whether for standard highway guardrails or specialized applications.

guardrail roll forming machine manufacturers company

3. Robust Construction High-quality materials and engineering ensure that these machines can withstand the rigors of continuous operation, resulting in longer service life and lower maintenance costs.

4. Integration of Technology Many manufacturers are now integrating automation and digital technologies into their roll forming machines. Features like computerized controls and real-time monitoring systems enhance operational efficiency and data tracking capabilities.

The Manufacturers’ Landscape

As the demand for guardrail systems continues to expand across global markets, numerous companies have established their presence as leading manufacturers of guardrail roll forming machines. These companies play a significant role in driving innovation and technological advancements within the industry.

1. Research and Development Continuous investment in R&D enables manufacturers to upgrade their machinery, developing better techniques, and more effective forms, ensuring they remain competitive in a rapidly evolving market.

2. Global Supply Chain Many manufacturers operate on an international scale, sourcing raw materials and components globally to optimize their production processes. This global reach allows them to respond to emerging markets and create better pricing strategies.

3. Customer-Centric Approach Leading guardrail roll forming machine manufacturers focus heavily on customer satisfaction, providing comprehensive support, including training, maintenance services, and customization options to suit specific needs.

Looking to the Future

As urbanization increases and road safety regulations become stricter, the role of guardrail roll forming machine manufacturers will likely grow more substantial. Innovations in manufacturing technologies, including green solutions and sustainable materials, are on the horizon, promising to reduce environmental impact while enhancing safety features.

Investments in smarter technologies, like artificial intelligence and machine learning, will enable manufacturers to produce even more efficient machines that can adapt to market demands quickly.

In conclusion, guardrail roll forming machine manufacturers play a crucial role in enhancing road safety infrastructure across the globe. By embracing technological innovation and focusing on quality and efficiency, these manufacturers are not only meeting current demands but are well-positioned to shape the future of road safety. Their contributions ensure safer travels for all, making them indispensable in the construction and manufacturing sectors.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025