glazed tile making machine factories

Exploring Glazed Tile Making Machine Factories A Gateway to Quality Ceramics

In the world of ceramics, glazed tiles hold a prominent position due to their durability, aesthetic appeal, and versatility. The process of producing these high-quality tiles is heavily reliant on advanced machinery, found in specialized glazed tile making machine factories. These factories play a crucial role in the ceramics industry, providing the technology needed to meet the increasing demand for glazed tiles in both residential and commercial applications.

Understanding the Manufacturing Process

The production of glazed tiles involves several stages, from raw material preparation to firing and glazing. At the heart of this process are the machines designed to handle each phase efficiently. Initially, the raw materials, including clay, feldspar, and quartz, are finely milled and blended. This is where the importance of high-quality tile-making machines is evident, as they ensure uniformity in the material, which is critical for achieving consistent tile quality.

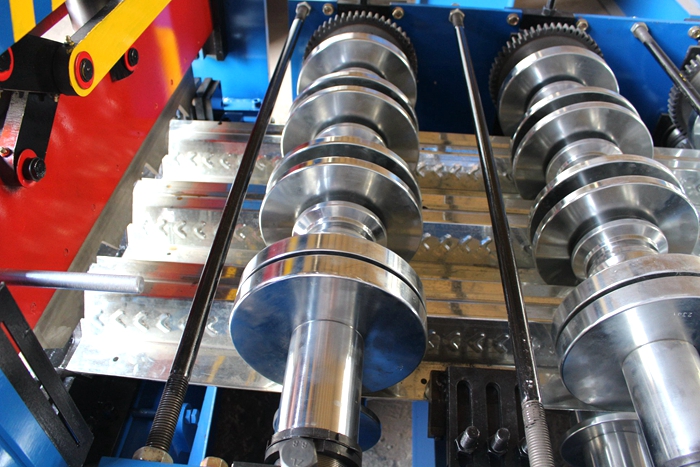

Once the materials are prepared, they are shaped into tiles using presses that can apply significant pressure to mold the mixture into the desired form. After shaping, the tiles undergo drying to remove excess moisture, which is essential for preventing defects during firing.

The next phase involves firing the tiles in kilns at high temperatures to sinter the particles and enhance their strength. This stage is critical; therefore, glazed tile making machine factories invest in advanced kiln technologies that ensure even heat distribution and optimal firing schedules.

The Role of Glazing Machines

glazed tile making machine factories

After the initial firing, the tiles are coated with a glaze—a glassy surface that enhances their durability and aesthetic quality. Glazing machines in these factories automate the application of glaze, ensuring a uniform layer that is crucial for both appearance and performance. The ability to customize glazes in various colors and finishes gives manufacturers a competitive edge in the market.

Quality Control and Innovation

Quality control is paramount in the tile manufacturing process. The best glazed tile making machine factories implement rigorous quality assurance protocols to monitor each stage of production. Automated inspection systems, often integrated into the production line, help identify defects early, minimizing waste and ensuring that only the best products reach the market.

Innovation is another hallmark of leading glazed tile making machine factories. As the demand for environmentally friendly and sustainable products grows, manufacturers are increasingly incorporating green technologies into their production processes. This includes the use of recycled materials and energy-efficient machinery, reducing the environmental impact of tile production.

Global Impact and Future Trends

The influence of glazed tile making machine factories extends beyond local economies; they play a pivotal role in global trade. Countries with strong ceramics industries are key exporters, meeting the demands of international markets. The future of these factories is bright, with trends indicating a shift towards smart manufacturing—where data analytics and IoT (Internet of Things) technologies will further enhance productivity and efficiency.

In conclusion, glazed tile making machine factories are essential players in the ceramics industry, equipped with advanced technology that ensures the production of high-quality tiles. With a focus on innovation and sustainability, these factories are not only meeting current market demands but are also paving the way for the future of tile manufacturing. As consumer preferences continue to evolve, these factories will be at the forefront, adapting and transforming to create products that blend functionality with aesthetic appeal.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025