glazed roof tile roll forming machine

Glazed Roof Tile Roll Forming Machine Revolutionizing Roofing Solutions

In recent years, the construction industry has witnessed a significant transformation, particularly in roofing solutions. Among the most innovative technologies shaping this sector is the glazed roof tile roll forming machine. This advanced machinery has been designed to produce high-quality glazed roof tiles that are not only aesthetically pleasing but also durable and cost-effective. This article will explore the functionality, benefits, and applications of glazed roof tile roll forming machines.

What is a Glazed Roof Tile Roll Forming Machine?

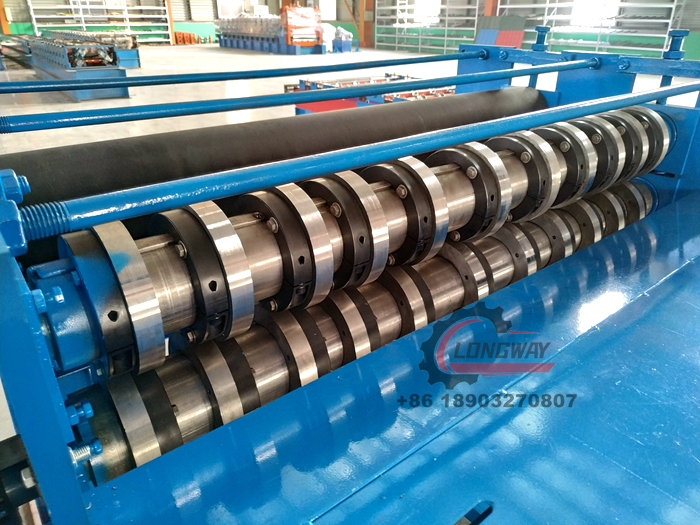

A glazed roof tile roll forming machine is specialized equipment used to manufacture roof tiles from metal sheets. This process involves feeding raw metal sheets into the machine, which then shapes and forms them into tiles using a series of rollers. The machine can produce various designs and profiles, mimicking traditional clay or concrete roof tiles but with added benefits. The glazed finish provides an attractive appearance and enhances the product’s durability, weather resistance, and longevity.

How Does It Work?

The operation of the glazed roof tile roll forming machine involves several key steps. First, the metal sheets, often made from steel or aluminum, are fed into the machine and cut to the desired length. The forming process then shapes these sheets into the desired tile profile. This is achieved through a series of adjustable rollers that are designed to bend, curve, and shape the metal into tiles that replicate traditional roofing materials.

Once the tiles are formed, they are coated with a glaze, which adds another layer of protection. The glazing process often involves applying a ceramic or polymer material that provides a shiny, durable finish. The result is a product that not only looks elegant but is also resistant to fading, erosion, and adverse weather conditions.

Benefits of Using Glazed Roof Tile Roll Forming Machines

glazed roof tile roll forming machine

1. Cost-Effectiveness One of the most significant advantages of using a glazed roof tile roll forming machine is cost savings. The production process is efficient, allowing manufacturers to produce tiles at a lower cost compared to traditional methods. This makes glazed metal roof tiles an attractive option for builders and homeowners.

2. Durability and Longevity Glazed roof tiles are inherently resistant to various environmental factors. Unlike traditional clay or concrete tiles, which can be prone to cracking, metal tiles can withstand harsher conditions and have a longer lifespan. Their resistance to rust and corrosion further enhances their durability.

3. Aesthetic Versatility The ability to create tiles in various shapes and colors is another advantage of utilizing a roll forming machine. This versatility allows builders and architects to achieve customized designs that enhance the overall aesthetics of any property. Whether it is a modern or traditional style, glazed roof tiles can complement a wide range of architectural designs.

4. Sustainability With the increasing focus on sustainability in construction, glazed metal roof tiles are an eco-friendly option. These tiles are often produced from recycled materials and can be fully recycled at the end of their lifespan. Additionally, their lightweight nature reduces the overall structural load, leading to less material use in roofing frameworks.

5. Fast Production The automated nature of roll forming machines allows for rapid production of tiles, reducing lead times for construction projects. This efficiency is crucial in today’s fast-paced building environment, where time often equals money.

Applications of Glazed Roof Tile Roll Forming Machines

Glazed roof tile roll forming machines are widely utilized in various applications. They are commonly used in residential roofing, commercial buildings, agricultural structures, and even in the construction of industrial facilities. The versatility of these tiles makes them suitable for both new constructions and renovations, providing a practical solution for builders and architects alike.

In conclusion, the glazed roof tile roll forming machine represents a leap forward in roofing technology. With its ability to produce high-quality, durable, and aesthetically pleasing tiles, it is transforming the roofing landscape. The benefits it offers, from cost-effectiveness to sustainability, make it an indispensable tool for manufacturers and builders striving to meet the demands of modern construction. As the industry continues to evolve, the glazed roof tile roll forming machine will undoubtedly play a pivotal role in shaping the future of roofing solutions.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025