Galvanized Steel Seam Roll Forming Equipment for Efficient Structural Fabrication

The Versatility of Galvanized Standing Seam Roll Forming Machines

In the realm of modern construction and architectural design, the choice of materials and techniques significantly influences durability, aesthetics, and overall structural integrity. Among various building components, roofing systems are pivotal in offering protection against environmental elements while enhancing visual appeal. One of the most sought-after solutions in contemporary roofing is the galvanized standing seam roof, a system characterized by its sleek lines and robust performance. To efficiently produce these roofing panels, manufacturers are increasingly turning to galvanized standing seam roll forming machines.

Understanding Galvanized Standing Seam Roofing

Before delving into the machinery, it is essential to understand what galvanized standing seam roofing entails. This roofing type is constructed from continuous panels that run from the ridge of the roof down to the eaves. The panels are joined with vertical seams that can be either mechanically or manually locked. The use of galvanized steel—a corrosion-resistant alloy created through a process of hot-dip galvanization—ensures that roofs can endure harsh weather conditions, making them a popular choice in both commercial and residential construction.

The Role of Roll Forming Machines

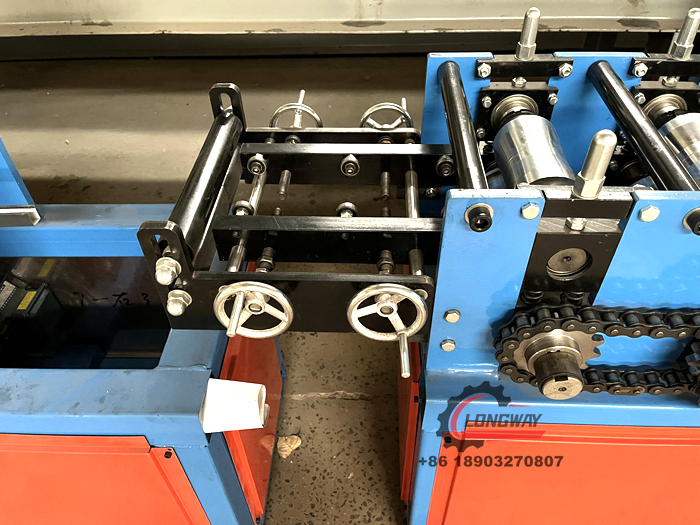

Roll forming machines play a crucial role in the production of roofing materials. These machines utilize a series of rollers to gradually shape a flat sheet of metal into a desired profile. The versatility of these machines allows for the production of various profiles, making them indispensable in the roofing industry.

Specifically, galvanized standing seam roll forming machines are designed to create precisely shaped panels that are both aesthetically pleasing and structurally sound. These machines operate by taking coils of galvanized steel and feeding them through a sequence of rollers. As the metal passes through the rollers, it is progressively formed into the standing seam profile, with the seams standing tall and ready for installation.

galvanized standing seam roll forming machine

Advantages of Using Galvanized Standing Seam Roll Forming Machines

1. Precision and Efficiency One of the most significant advantages of using roll forming machines is their ability to produce panels with extreme precision. This ensures that each panel fits together perfectly, reducing the chances of leaks and enhancing the roof's overall performance. Additionally, automated machinery can significantly increase production speeds, allowing manufacturers to fulfill large-scale orders more efficiently.

2. Material Optimization Galvanized standing seam roll forming machines utilize materials optimally, minimizing waste. By creating panels directly from metal coils, manufacturers maximize material usage, ultimately contributing to more sustainable practices.

3. Customizable Solutions These machines can be easily adjusted to create different panel widths and seam heights, catering to unique design specifications. This adaptability is advantageous for architects and builders who are seeking to innovate and personalize roofing aesthetics while adhering to functional requirements.

4. Durability and Cost-Effectiveness Galvanized steel, known for its durability, ensures that roofs are long-lasting and require minimal maintenance. By investing in standing seam roofing systems produced through roll forming machines, property owners can benefit from lower long-term costs associated with repairs and replacements.

Conclusion

The galvanized standing seam roll forming machine represents a significant advancement in roofing technology, providing manufacturers and builders with the tools necessary to produce high-quality, durable roofing systems. As the construction industry continues to evolve, the demand for versatile, efficient, and aesthetically pleasing roofing options is likely to remain strong. The incorporation of advanced machinery not only enhances production capabilities but also addresses the growing need for sustainable and resilient building solutions. In summary, galvanized standing seam roll forming machines stand at the forefront of modern roofing design, combining functionality with cutting-edge technology to meet the demands of the future.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025