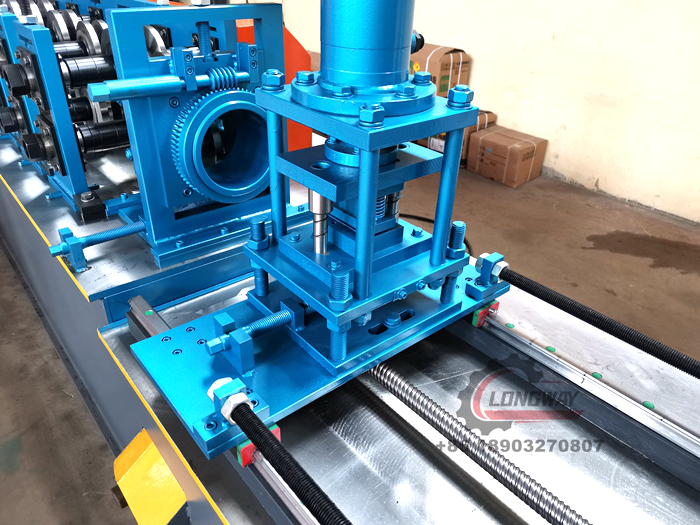

galvanized panel roll forming machine

The Importance of Galvanized Panel Roll Forming Machines in Modern Manufacturing

In the contemporary manufacturing landscape, efficiency and durability are paramount. Among the myriad of machines that cater to these demands, galvanized panel roll forming machines stand out as essential tools. These machines are designed to produce high-quality, corrosion-resistant panels used in various applications, from roofing to wall cladding. The significance of these machines can be understood by exploring their operation, benefits, and applications.

Galvanized panel roll forming machine operates through a continuous process that transforms flat metal sheets into specific shapes and sizes. The steel sheets undergo a series of roll stations, where they are gradually shaped into desired profiles. The galvanized steel used in this process is coated with a layer of zinc, which serves as a protective barrier against rust and environmental factors. This feature is crucial for ensuring longevity, particularly for structures exposed to harsh weather.

One of the standout benefits of utilizing galvanized panel roll forming machines is their efficiency. These machines can operate at high speeds, significantly increasing production rates while maintaining precision in the dimensions of the panels. This efficiency translates into reduced labor costs and lower production times, allowing manufacturers to meet market demands swiftly. Furthermore, the automation of these machines minimizes human error, ensuring consistent quality across batches.

galvanized panel roll forming machine

In addition to efficiency, the strength and resilience of galvanized panels cannot be overlooked. The galvanized coating provides excellent resistance to oxidation, making the panels impervious to rust and corrosion. This quality is particularly advantageous for construction applications, where the integrity of materials is crucial. Buildings, warehouses, and industrial facilities benefit from the durability that galvanized panels provide, ultimately leading to lower maintenance costs and longer service life.

The versatility of galvanized panel roll forming machines also contributes to their popularity. These machines can produce a wide range of panel profiles, catering to various design requirements. From traditional standing seam roofs to modern wall cladding systems, manufacturers can create customized solutions that meet specific aesthetic and functional needs. This adaptability is essential in an era where architectural innovation is constantly evolving.

Moreover, the environmental impact of using galvanized materials should not be disregarded. The longevity of galvanized panels means they do not need to be replaced as frequently as non-galvanized alternatives, thereby reducing waste. Additionally, the production process for galvanized steel is becoming increasingly sustainable, with many manufacturers adopting eco-friendly practices and utilizing recycled materials.

In conclusion, the galvanized panel roll forming machine represents a cornerstone of modern manufacturing, combining efficiency, durability, and versatility. As industries continue to expand and evolve, the reliance on high-quality, corrosion-resistant panels will only grow. Investing in these machines is not just a decision for improved production; it is a commitment to sustainability and quality that can enhance a company’s reputation and operational capacity. The future of construction and manufacturing is undoubtedly intertwined with the capabilities offered by galvanized panel roll forming machines, making them an invaluable asset in today’s market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025