Manufacturers of Forming Machines for Galvanized Metal Profiles and Components

Understanding Galvanized Metal Con Profiles and Forming Machines

In the modern construction and manufacturing industries, the demand for durable and corrosion-resistant materials has surged. Among these, galvanized metal profiles have gained immense popularity due to their strength, longevity, and versatility. This article explores the significance of galvanized metal profiles, the process of forming them, and the manufacturers specializing in forming machines for these materials.

What are Galvanized Metal Profiles?

Galvanized metal profiles refer to steel or iron products that have been coated with a layer of zinc to protect them from corrosion. This galvanization process involves immersing the metal in molten zinc, allowing it to form a protective barrier, which significantly extends the lifespan of the metal, especially in harsh environments. Such profiles are widely used in various applications, from construction frames and roofing materials to automotive parts and furniture.

The Importance of Forming Machines

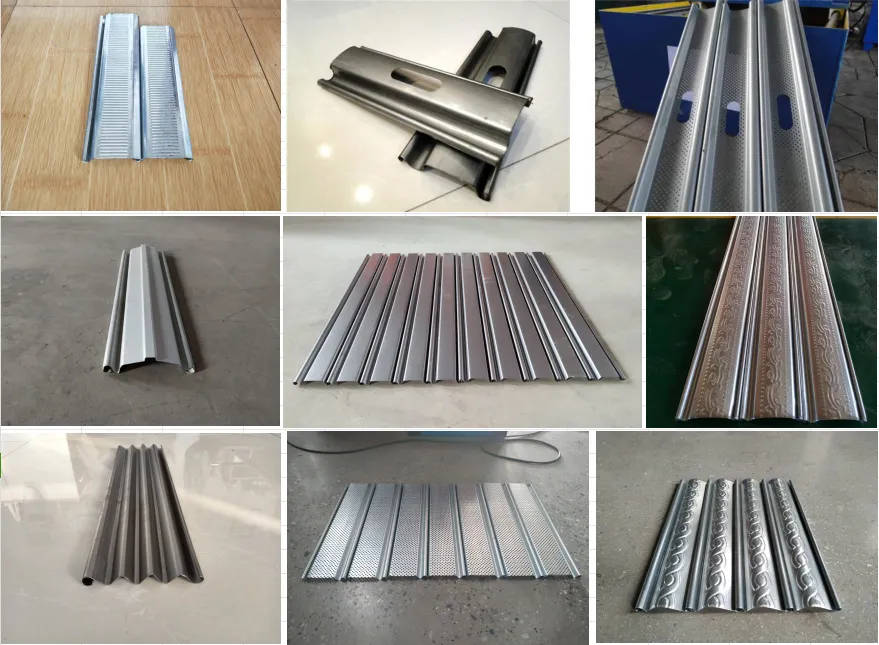

To create precise and high-quality galvanized metal profiles, manufacturers rely on specialized forming machines. These machines can convert flat sheets of galvanized metal into intricate shapes, allowing for the production of customized profiles that meet specific design requirements. The process involves several steps, including cutting, bending, and shaping the material to achieve the desired geometry.

Forming machines for galvanized metal are equipped with advanced technology to ensure accuracy and efficiency. They utilize computer numerical control (CNC) systems that automate the forming process, reducing labor costs and minimizing human error. As a result, high-speed production can be achieved while maintaining consistent quality and tolerances.

Key Features of Galvanized Metal Profile Forming Machines

1. Versatility Modern forming machines are designed to produce a wide range of profiles, from simple shapes to complex configurations. This versatility allows manufacturers to cater to diverse industries and applications.

galvanized metalcon perfiles forming machine manufacturers

2. Efficiency With automated processes and advanced controls, forming machines can significantly reduce production times while increasing output. This efficiency is essential for meeting market demands and staying competitive.

3. Durability These machines are built to withstand the rigors of continuous operation, featuring robust construction and high-quality components that ensure longevity and reliability.

4. Customization Many manufacturers offer tailored solutions that allow businesses to create uniquely shaped profiles according to their specific needs. This customization is vital in ensuring the final product fits perfectly within the intended application.

Leading Manufacturers of Forming Machines

The market for galvanized metal profile forming machines is populated with various manufacturers that excel in producing high-quality equipment. Companies like Zhaoyuan Jinhai, Fenghua Machinery, and Guangdong Jinteng have established themselves as leaders in this field. They are known for their state-of-the-art technology, comprehensive service offerings, and dedication to customer satisfaction.

Furthermore, many of these manufacturers provide additional services such as training, maintenance support, and technical consultation to help clients maximize their production capabilities.

Conclusion

As the demand for galvanized metal profiles continues to grow, the importance of efficient and reliable forming machines becomes increasingly evident. Manufacturers that specialize in producing these machines play a crucial role in enabling the construction and manufacturing sectors to produce high-quality, durable products. By staying abreast of technological advancements and responding to industry demands, these manufacturers contribute significantly to the evolution of modern construction and design, ensuring that galvanized metal profiles remain a cornerstone of resilient infrastructure and innovative projects.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025