Top Manufacturers of Furring Channel Roll Forming Machines for Efficient Construction Solutions

The Role of Furring Channel Roll Forming Machines in Modern Construction

In today's construction industry, the demand for efficient and precise building materials has skyrocketed. One of the notable innovations that have significantly contributed to construction efficiency is the furring channel roll forming machine. This machinery is designed to manufacture furring channels, which are essential components in various drywall systems, ceilings, and interior framing. Understanding the importance, functionality, and benefits of these machines can provide insight into the modern construction landscape.

What are Furring Channels?

Furring channels are metal framing components typically made from galvanized steel or aluminum. They serve as a framework over which drywall or other materials can be mounted. By providing a level base for mounting these materials, furring channels help ensure that walls and ceilings are smooth and structurally sound. Moreover, they are crucial for insulation and can also facilitate the installation of lighting fixtures and other electrical components.

The Functionality of Furring Channel Roll Forming Machines

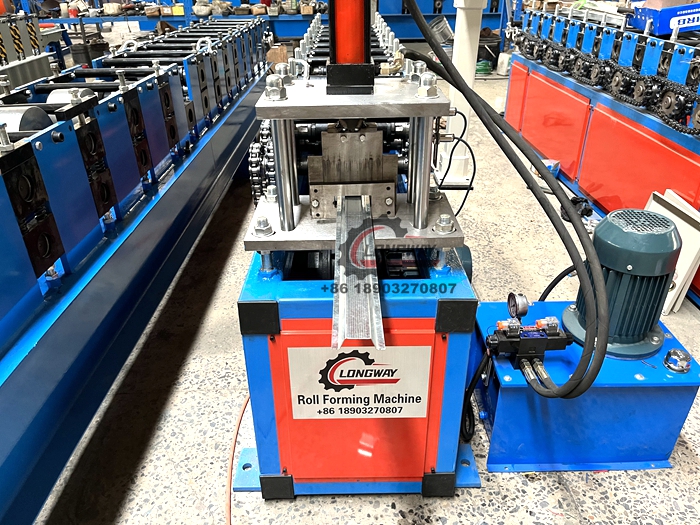

Furring channel roll forming machines are engineered to convert flat metal sheets into seamlessly shaped furring channels in a continuous process. The machines utilize a series of rollers to bend and shape metal while it passes through, creating uniform channels with precise dimensions. This automation ensures that manufacturers can produce large quantities of furring channels quickly and consistently, thus meeting the high demands of the construction market.

The setup of a roll forming line typically includes a decoiler (for unwinding coils), a roll forming machine (for shaping), cutting equipment, and a stacking system. Advanced models can integrate quality control systems to monitor the thickness and dimensions of the channels in real-time, ensuring that the end product meets stringent quality standards.

Benefits of Using Furring Channel Roll Forming Machines

1. Efficiency One of the primary advantages of roll forming technology is its efficiency. These machines can produce large volumes of furring channels in a relatively short period. This increased production capacity allows companies to meet tight deadlines and fulfill large orders without compromising quality.

furring channel roll forming machine companies

2. Cost-Effectiveness By utilizing a roll forming machine, manufacturers can reduce labor costs and minimize waste. The precision of the process means less scrap material, and the speed of production can lead to lower operational costs.

3. Customization Modern furring channel roll forming machines can be easily adjusted to produce channels in different sizes and configurations. This flexibility allows manufacturers to cater to specific client needs and project requirements without investing in multiple machines.

4. Durability The materials used in furring channel production, combined with the manufacturing process, result in channels built to last. The galvanized steel or aluminum is not only lightweight but also resistant to corrosion and other environmental factors, making them ideal for diverse construction applications.

The Future of Furring Channel Roll Forming

As construction technology continues to evolve, the role of furring channel roll forming machines will remain vital. Innovations such as automation, improved software for production management, and integration with Industry 4.0 technologies promise to transform the way construction materials are produced. Companies can expect even higher efficiency rates, better material usage, and products that meet evolving building standards.

Moreover, with the increasing emphasis on sustainability in construction, the development of eco-friendly production processes and materials is likely to gain traction. Manufacturers of furring channel roll forming machines are beginning to incorporate green technologies that minimize environmental impact.

Conclusion

Furring channel roll forming machines exemplify the shift towards mechanized production in construction. Their role in manufacturing essential building components underscores their importance in enhancing construction efficiency and quality. As the industry embraces new technologies and sustainability, these machines will continue to evolve, playing a crucial part in building the structures of tomorrow. The future of construction is not only about the materials we use but also about the processes we employ to create them, and furring channel roll forming machines are at the forefront of this revolution.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025