Furring Channel Production Equipment for Efficient Wall and Ceiling Framing

The Furring Channel Machine Innovations in Construction

In the ever-evolving world of construction, efficiency and precision are paramount. One of the key innovations that has emerged to streamline the building process is the furring channel machine. This machine plays a crucial role in the installation of various building materials, particularly in the framing and finishing stages of construction. It is designed to create reliable and durable furring channels, which are essential for attaching insulation and other materials to walls and ceilings.

Furring channels are typically metal tracks that serve as a base for mounting gypsum board, drywall, or other materials. They help to flatten irregular surfaces, provide added support, and create a space for insulating materials. The furring channel machine automates the production of these vital components, thus reducing manual labor and minimizing human error during the construction process.

One of the primary advantages of using a furring channel machine is its ability to produce channels with consistent specifications. This consistency is crucial in ensuring that all components fit together correctly, thus reducing the need for adjustments on-site. Additionally, the machine operates at a significantly higher speed compared to traditional manual methods. This increase in production efficiency allows contractors to complete projects in a timely manner, ultimately lowering labor costs and contributing to overall project budgets.

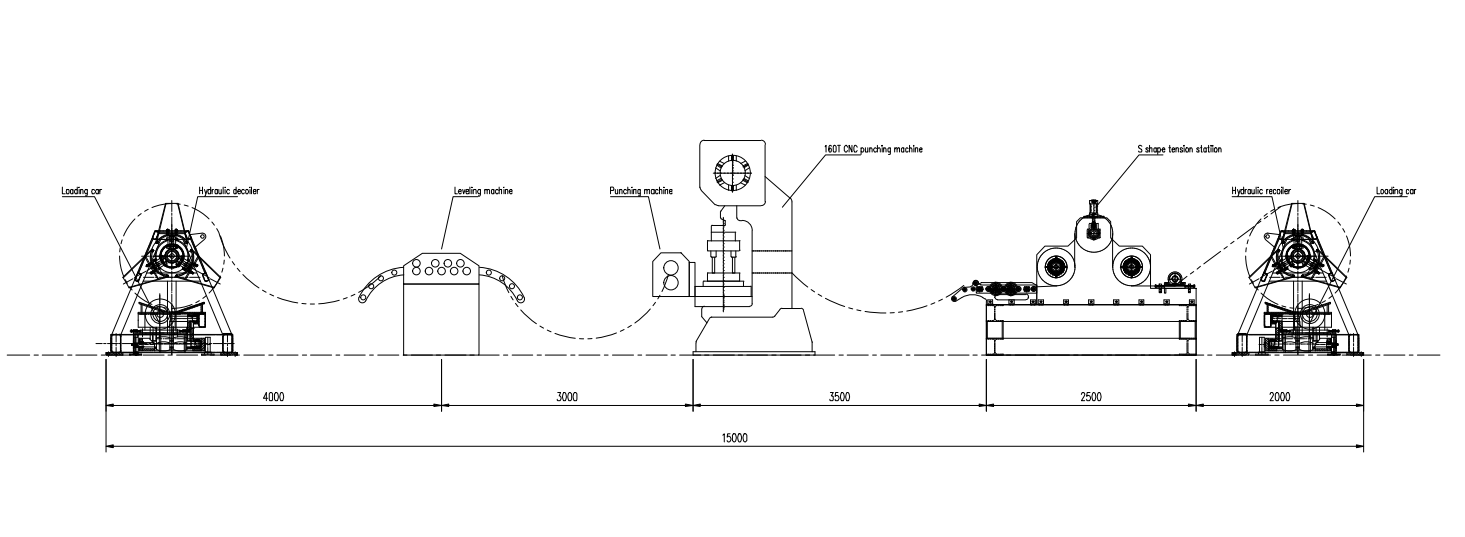

furring channel machine

Modern furring channel machines are equipped with advanced technology that enhances their functionality. Some machines feature programmable settings that allow operators to customize the dimensions and specifications of the channels based on specific project requirements. This flexibility is invaluable for contractors who work on a variety of projects, as it allows them to adapt to different clients’ needs without the need for additional equipment.

Moreover, these machines often incorporate safety features that ensure a secure working environment. With automated tasks, the risk of accidents associated with manual handling is significantly reduced. Workers are thus able to focus on oversight rather than complex fabrication tasks, improving overall workplace safety and productivity.

In conclusion, the furring channel machine represents a significant step forward in the construction industry. By enhancing the efficiency, safety, and quality of furring channel production, this machine not only simplifies the building process but also supports the growing demand for sustainable and cost-effective construction practices. As technology continues to evolve, we can expect further advancements in machinery that will reshape the future of construction, making it not only faster but also more reliable. Construction professionals who invest in these machines will likely gain a competitive edge in the industry, positioning themselves as leaders in innovation and quality.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025