Full Auto C Z Purlin Roll Forming Machine | High Speed & Precision

Introduction to Automated Purlin Production

In modern construction and industrial fabrication, the demand for high-quality, precisely formed C and Z purlins is ever-increasing. These structural components are critical for supporting roofs and walls in various building types, from commercial warehouses to large-span industrial facilities. Meeting this demand efficiently and cost-effectively requires advanced machinery. The Full Auto C Z purlin Roll forming machine represents the pinnacle of this technology, offering unparalleled automation, precision, and versatility in purlin production. This comprehensive guide explores its technical intricacies, operational advantages, and strategic implications for B2B stakeholders.

Industry Trends and Market Demand

The global construction industry is experiencing a significant shift towards modular construction, prefabrication, and sustainable building practices. This trend fuels the demand for standardized, lightweight, and high-strength structural elements like C and Z purlins. Key drivers include:

- Increased Automation: Manufacturers are investing in fully automated systems to reduce labor costs, increase production speed, and enhance product consistency.

- Material Optimization: Focus on high-tensile strength steel and advanced coatings to extend service life and improve structural integrity, directly impacting purlin design.

- Customization & Flexibility: Demand for machines capable of producing a wide range of purlin sizes and profiles to meet diverse project specifications without extensive retooling.

- Energy Efficiency: Drive towards more energy-efficient manufacturing processes and the use of sustainable materials in building construction.

- Global Infrastructure Development: Rapid urbanization and infrastructure projects in emerging economies are creating vast opportunities for prefabricated steel structures.

These trends underscore the critical role of advanced roll forming technology, making the investment in a Full Auto C Z purlin Roll forming machine a strategic imperative for businesses aiming for market leadership.

Detailed Process Flow of the Full Auto C Z Purlin Roll Forming Machine

The manufacturing process orchestrated by a Full Auto C Z purlin Roll forming machine is a marvel of synchronized engineering. It transforms flat steel coils into finished C or Z purlins with exceptional precision and speed. The typical process involves several integrated stages:

Key Stages and Materials:

- Decoiling: High-quality steel coils, typically galvanized steel (e.g., Q235, Q345, G300, G450, G550), are loaded onto a hydraulic or manual decoiler. This unit ensures smooth and consistent feeding of the material into the machine. The material's yield strength and tensile strength are crucial for the final product's structural integrity.

- Feeding and Leveling: The steel strip passes through a feeding guide and a leveling mechanism. This ensures the material is perfectly flat and aligned before entering the forming section, critical for dimensional accuracy and preventing warping.

- Pre-Punching and Pre-Cutting: Utilizing a hydraulic punching system, holes for bolts and other fixtures are precisely punched into the flat strip. This can be performed before the roll forming process, ensuring clean, deformation-free holes. Some advanced machines also feature pre-cutting capabilities for enhanced efficiency. The tooling for these processes often uses high-grade tool steel (e.g., Cr12Mov) that has undergone forging, CNC machining, and heat treatment to achieve superior hardness and wear resistance.

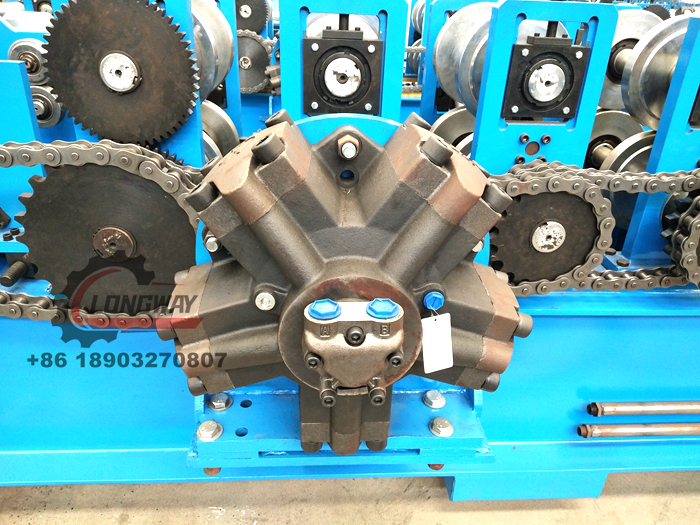

- Roll Forming: The core of the machine, consisting of multiple sets of forming rollers (typically 12-18 stations), gradually shapes the flat steel strip into the desired C or Z purlin profile. Each station progressively bends the material until the final profile is achieved. Rollers are precision-machined from high-quality steel (e.g., GCr15 bearing steel or 45# steel with chrome plating) and hardened to withstand continuous operation.

- Post-Cutting (Flying Shear): Once the purlin reaches the programmed length, a hydraulic flying shear system cuts the purlin without stopping the continuous production line. This significantly boosts productivity. The cutting blade, like the punching dies, is crafted from hardened tool steel.

- Output & Stacking: Finished purlins are automatically transferred to an output table or stacking system, ready for packaging or further processing.

Testing Standards and Service Life:

Adherence to international standards is paramount. Our machines are designed and manufactured to comply with ISO 9001:2015 quality management systems and CE certification for European markets, ensuring operational safety and product quality. Key components like motors, bearings, and hydraulic systems often meet ANSI or DIN standards. The typical service life of a well-maintained Full Auto C Z purlin Roll forming machine is 15-20 years, with critical components such as rollers and cutting dies designed for millions of cycles before requiring replacement, minimizing downtime and maximizing ROI.

Target Industries and Advantages:

These machines are indispensable across various industries focused on construction and infrastructure:

- Construction (Commercial & Industrial): Fabrication of purlins for warehouses, factories, shopping malls, and agricultural buildings.

- Prefabricated Housing: Essential for producing standardized structural components for modular and prefabricated homes.

- Solar Panel Mounting Systems: Producing custom purlin profiles for solar farm structures.

- Infrastructure Projects: Used in sheds, shelters, and support structures for various large-scale developments.

Advantages in these scenarios include significant energy savings due to optimized production cycles and reduced material waste, superior corrosion resistance when using pre-galvanized steel, and consistent product quality, which reduces on-site erection time and labor.

Technical Specifications and Parameters

The performance of a Full Auto C Z purlin Roll forming machine is defined by its robust technical specifications. These parameters dictate its capabilities, efficiency, and the quality of the output. Below is a representative table illustrating typical specifications for a high-performance model:

| Parameter | Value/Description |

|---|---|

| Material Thickness | 1.5mm - 3.2mm (up to 4.0mm upon request) |

| Material Width | 400mm - 600mm (adjustable) |

| Purlin Web Height | 80mm - 300mm (adjustable) |

| Purlin Flange Width | 40mm - 80mm (adjustable) |

| Lip Height | 10mm - 25mm (adjustable) |

| Forming Speed | Up to 25-30 m/min (with punching) |

| Forming Stations | 16-18 roller sets (typically) |

| Main Motor Power | 15 kW - 22 kW |

| Hydraulic Power | 7.5 kW - 11 kW |

| Control System | PLC with Touch Screen HMI (e.g., Siemens, Panasonic, Mitsubishi) |

| Machine Weight | Approx. 10 - 15 Tons (main machine) |

| Dimension (L x W x H) | Approx. 10m x 2m x 1.5m |

These specifications highlight the machine's capability to handle a wide range of material gauges and produce diverse purlin profiles, making it highly adaptable to varying project requirements. The robust PLC control system ensures precise operation and easy adjustment of parameters.

Application Scenarios and Technical Advantages

The versatility of the Full Auto C Z purlin Roll forming machine translates into broad application potential across numerous construction sectors.

Typical Application Scenarios:

- Large Span Steel Structures: Supplying purlins for industrial plants, logistics centers, exhibition halls, and sports arenas where wide spans require strong, lightweight roofing support.

- Agricultural Buildings: Efficiently producing purlins for barns, greenhouses, and livestock shelters, often requiring rapid deployment and cost-effectiveness.

- Commercial Buildings: Used in the construction of supermarkets, office blocks, and retail units where consistent quality and quick assembly are crucial.

- Building Renovation and Extension: Providing custom-length and specific profile purlins for existing structures, minimizing disruption and ensuring compatibility.

Core Technical Advantages:

- High Degree of Automation: PLC control, servo-driven feeding, and automated cutting minimize human intervention, leading to higher accuracy and reduced labor costs.

- Rapid Profile Change: Advanced models feature quick-change systems, allowing operators to switch between C and Z profiles or different sizes within minutes, significantly enhancing production flexibility.

- Integrated Punching and Cutting: Pre-punching and flying shear technologies ensure precise hole placement and clean cuts at high speeds, eliminating secondary operations.

- Superior Product Quality: Precision-engineered rollers and robust machine frames minimize deformation and ensure consistent profile dimensions, critical for structural integrity and ease of assembly.

- Material Efficiency: Optimized cutting algorithms and minimal scrap rates contribute to significant material savings, enhancing cost-effectiveness.

- Enhanced Safety Features: Comprehensive safety guarding, emergency stops, and interlocks protect operators and ensure compliance with industrial safety standards.

Vendor Comparison and Customization Solutions

When selecting a Full Auto C Z purlin Roll forming machine, discerning buyers consider not only the machine's capabilities but also the vendor's reputation, support, and ability to provide tailored solutions.

Key Vendor Comparison Criteria:

| Criterion | Leading Vendor Qualities | Less Optimal Vendor Qualities |

|---|---|---|

| Technology & Innovation | Latest PLC, servo systems, quick-change tooling, flying shear technology. | Outdated control systems, manual adjustments, slower production speeds. |

| Material & Build Quality | High-grade steel for rollers (GCr15), robust frame (H-beam), reputable component brands (Siemens, Schneider). | Lower quality steel, less stable frame, generic electrical components leading to frequent breakdowns. |

| Customization Capability | Ability to adapt machine for specific purlin profiles, material gauges, punching patterns, or integration with existing lines. | Offers only standard models with no flexibility for client-specific requirements. |

| After-Sales Support & Warranty | Comprehensive warranty (1-2 years), readily available spare parts, prompt technical support (online/on-site). | Limited warranty, difficulty sourcing spare parts, delayed or non-existent support. |

| Certifications & Compliance | ISO 9001, CE, TUV certifications; adherence to regional safety and quality standards. | Lack of verifiable certifications or compliance with international standards. |

Customized Solutions:

Leading manufacturers understand that one size does not fit all. Customization options for the Full Auto C Z purlin Roll forming machine can include:

- Specific Purlin Profiles: Tailoring roller designs for unique C, Z, or even custom U/sigma profiles required for specialist projects.

- Enhanced Material Handling: Integration with heavier-duty decoilers, coil cars, or automatic stacking systems for large-scale operations.

- Advanced Punching Patterns: Development of custom punching dies to accommodate complex bolt hole configurations or specialized connection requirements.

- PLC Integration: Compatibility with existing factory automation systems or specific PLC brands (e.g., Allen-Bradley, Omron) preferred by the client.

- Varying Speed Requirements: Optimizing motor and hydraulic systems to achieve higher production speeds or specialized low-speed operations.

Application Case Studies and Customer Experience

Real-world applications demonstrate the tangible benefits of investing in a high-quality Full Auto C Z purlin Roll forming machine.

Case Study 1: Large-Scale Industrial Warehouse Project

A major construction firm tasked with building a 50,000 square meter logistics center in Southeast Asia required over 300,000 linear meters of C and Z purlins in varying lengths and thicknesses. By deploying a Full Auto C Z purlin Roll forming machine, the firm achieved:

- Production Efficiency: Averaged 28 meters per minute, completing the purlin fabrication within 3 months, well ahead of schedule.

- Cost Savings: Reduced labor costs by 40% compared to previous semi-automatic methods, and minimized material waste to under 2% through precise cutting.

- Consistent Quality: All purlins met strict tolerance requirements (±0.5mm length, ±0.3mm profile), ensuring smooth on-site assembly and structural integrity.

Case Study 2: Prefabricated Modular Housing Manufacturer

A leading manufacturer of modular homes needed a flexible solution to produce custom-length C purlins for different building modules. The integration of a quick-change Full Auto C Z purlin Roll forming machine with a sophisticated software interface allowed them to:

- Minimize Changeover Time: Switch between purlin dimensions and punching patterns in less than 5 minutes, facilitating batch production of varied components.

- Improve Design Flexibility: Easily accommodate last-minute design changes by updating CAD files directly linked to the machine's PLC.

- Enhance Profit Margins: The automation reduced reliance on skilled labor and boosted output, contributing to a 15% increase in production capacity.

Trustworthiness: FAQ, Lead Time, Warranty & Support

Frequently Asked Questions (FAQ):

- Q1: What is the maximum thickness of steel the machine can process?

- A1: Our standard Full Auto C Z purlin Roll forming machine can process galvanized steel up to 3.2mm thick. Custom solutions for up to 4.0mm are available upon request.

- Q2: Can the machine switch between C and Z profiles automatically?

- A2: Yes, advanced models are equipped with an automatic C/Z profile changing system, allowing seamless transitions via the HMI in typically 5-10 minutes.

- Q3: What level of automation can I expect?

- A3: The machine is fully automatic, featuring hydraulic decoiling, servo feeding, pre-punching, pre-cutting, roll forming, and a high-speed flying shear cut-off, all controlled by a user-friendly PLC system.

- Q4: What are the typical dimensions of a C or Z purlin this machine can produce?

- A4: It can produce C/Z purlins with web heights from 80-300mm, flange widths from 40-80mm, and lip heights from 10-25mm. All dimensions are adjustable.

Lead Time & Fulfillment Details:

Standard lead time for a new Full Auto C Z purlin Roll forming machine is typically 60-90 working days from deposit receipt, depending on customization requirements and current production schedules. We provide regular updates throughout the manufacturing process, from raw material procurement to final assembly and testing. Pre-shipment inspections (PSI) by the client or a third-party agency are welcomed.

Warranty Commitments:

Each machine comes with a comprehensive 12-month warranty covering mechanical and electrical components, excluding wear parts. We guarantee against manufacturing defects and offer replacement parts free of charge during this period. Extended warranty options are available.

Customer Support Information:

Our dedicated after-sales support team is available 24/7. We offer:

- Remote Technical Assistance: Troubleshooting via video calls, email, and phone.

- On-Site Installation & Training: Experienced engineers can be dispatched for machine installation, commissioning, and operator training worldwide.

- Spare Parts Supply: A robust inventory of essential spare parts ensures minimal downtime.

- Maintenance Services: Scheduled preventive maintenance programs to ensure optimal performance and extend machine life.

Conclusion

The Full Auto C Z purlin Roll forming machine stands as a testament to modern industrial engineering, offering a blend of high automation, unparalleled precision, and robust versatility. For B2B stakeholders in the construction and fabrication industries, investing in such advanced machinery is not merely an equipment purchase but a strategic decision to enhance operational efficiency, reduce costs, expand production capabilities, and maintain a competitive edge in a rapidly evolving market. With its capacity for rapid profile change, integrated punching and cutting, and adherence to stringent quality standards, it is a pivotal asset for future-proofing manufacturing operations and delivering superior structural components.

References

- Cold Formed Steel Engineers Institute (CFSEI) - Technical Notes on Purlin Design and Fabrication.

- International Organization for Standardization (ISO) - ISO 9001:2015 Quality Management Systems.

- European Committee for Standardization (CEN) - EN 10162: Cold rolled steel sections - Technical delivery conditions - Dimensional and cross-sectional tolerances.

- American Iron and Steel Institute (AISI) - North American Specification for the Design of Cold-Formed Steel Structural Members.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025