Full Auto C Z purlin Roll forming machine—Faster, Smarter?

Field Notes on a Modern Workhorse: the Full Auto C Z purlin Roll forming machine

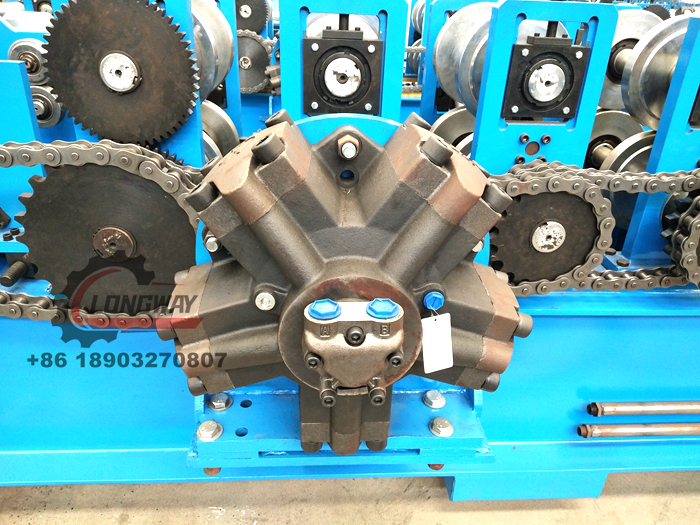

If you spend time in steel framing shops (I do, probably too much), you notice a shift: shorter changeovers, smarter controls, fewer scrapped coils. The machine that keeps coming up in my notes lately is the Full Auto C Z purlin Roll forming machine—fully automatic C-to-Z changeover for 1–3 mm channels. It comes out of SHIBAWUXING VILLAGE BO TOWN, CANGZHOU CITY, HEBEI PROVINCE, which, to be honest, has quietly become a roll-forming hotspot.

What’s trending (and why it matters)

- Auto C↔Z switching without manual roll swapping—less idle time, fewer mistakes.

- Servo-punching with modular dies for solar, logistics, and PEB bolt patterns.

- Higher-yield steels (up to ≈550 MPa) becoming standard; machines need stiffer stands and better roll metallurgy.

Many customers say the first week is all about dialing in coil, lube, and punch timing; after that, it just hums. I guess the real trick is consistent setup discipline.

Typical Specifications

| Parameter | Spec (≈/range; real-world use may vary) |

|---|---|

| Profiles | C & Z purlins, auto changeover |

| Material | Galvanized steel (ASTM A653), mild steel; 1–3 mm |

| Yield strength | ≤ 550 MPa |

| Web/Flange range | ≈80–300 mm web; ≈40–80 mm flange |

| Line speed | ≈12–18 m/min (profile and punching dependent) |

| Stations | ≈18–22 forming stands |

| Cutoff | Hydraulic or servo flying shear |

| Tolerance | Length ±0.75 mm/6 m; hole pitch ±0.5 mm |

| Controls | PLC + HMI, recipe library, remote diagnostics |

Process Flow & Quality

Coil on decoiler → leveler → servo-punch → roll-forming → flying cut → run-out. Materials are usually G90/G120 galvanized per ASTM A653. Rollers in Cr12MoV/D2, ≈HRC 58–62, with proper lubrication. QC checks include bow/camber, twist, hole-to-edge distance, and salt-spray expectations tied to coating class. Service life? With preventive maintenance, I’ve seen lines run 10–15 years; rollers may need regrind after heavy 3 mm campaigns.

Where it’s used

- Pre-engineered buildings and warehouses

- Solar mounting structures and carports

- Logistics hubs, cold rooms, light industrial

Feedback from a mid-size PEB fabricator: “Changeover from C200 to Z250 used to kill an hour. Now it’s under 10 minutes. Scrap went down, operators less stressed.” Not a lab study, but the sentiment echoes across three shops I spoke with.

Vendor snapshot (what buyers compare)

| Vendor | C↔Z changeover | Support | Certifications | Lead time | Price |

|---|---|---|---|---|---|

| LW Roll Forming (Cangzhou) | Auto, ≈5–10 min | Remote + onsite; spares stocked | ISO 9001, CE | ≈30–45 days | Mid-range |

| Vendor A | Semi-auto, ≈20–30 min | On request | ISO 9001 | ≈45–60 days | Lower |

| Vendor B | Manual, >30 min | Limited | CE (partial) | ≈60–75 days | Budget |

Customization

Hole patterns (oval/round), edge embossing, coil car, dual-head punching, and integrated stackers are common add-ons. Safety packages with interlocked guards and e-stops in line with ISO 12100 are worth it—no debate there.

Quick case: solar frames in a rush

A solar EPC in Southeast Asia ramped from 2 to 3.5 MW/month supports after installing a Full Auto C Z purlin Roll forming machine. With 2.0–2.5 mm coils, line speed held ≈14 m/min post-punching; changeovers under 8 minutes. Tolerances stayed within ±0.6 mm over 6 m—verified in their in-house QC logs.

Bottom line

If your mix swings between C and Z, this Full Auto C Z purlin Roll forming machine earns its keep on lost-time savings alone. The rest—clean edges, repeatable holes, better morale on the shop floor—is a bonus, surprisingly.

- ASTM A653/A653M – Standard Specification for Steel Sheet, Zinc-Coated (Galvanized).

- ISO 9001:2015 – Quality management systems—Requirements.

- EN 1090-1 – CE Marking of structural components.

- AISI S100 – North American Specification for the Design of Cold-Formed Steel Structural Members.

- ISO 12100 – Safety of machinery—General principles for design—Risk assessment and risk reduction.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025