formadora perfil metalcon canal

The Role of Formadora in the Metalcon Industry A Comprehensive Profile

In today’s fast-evolving industrial landscape, the Metalcon sector stands out as a critical foundation for various construction and manufacturing processes. At the heart of this sector is the role of the formadora, a professional whose expertise is indispensable in shaping the products that meet modern standards. This article aims to explore the profile of a formadora in the Metalcon industry, highlighting their skills, responsibilities, and the significance of their work.

Understanding the Formadora's Role

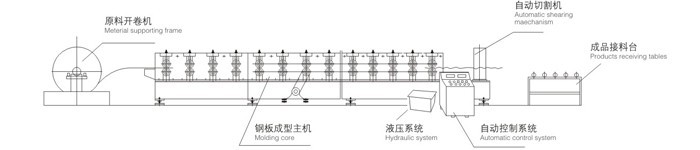

The term 'formadora' refers to a specialist skilled in the fabrication and molding of metal components used extensively in construction and manufacturing. Their work often involves using advanced machinery and tools to create metal sheets, structures, and components that serve specific functions within larger systems. This role is pivotal in ensuring that products not only meet design specifications but also adhere to safety and regulatory standards.

Key Skills and Qualifications

To excel in the role of a formadora, several key skills and qualifications are essential

1. Technical Proficiency A strong understanding of machinery and tools used in metal forming is necessary. Familiarity with Computer Numerical Control (CNC) machines, welding equipment, and various forming processes such as stamping, bending, and cutting is crucial.

2. Attention to Detail The formadora must have an acute attention to detail. Precision is necessary when working with metal, as even small discrepancies can lead to significant issues in the final product.

3. Problem-Solving Skills Challenges often arise during the shaping and forming process. A successful formadora must be able to quickly analyze problems and devise effective solutions to ensure that production schedules are maintained.

4. Safety Awareness Working with metal and heavy machinery poses inherent risks. Formadoras must be well-versed in safety protocols and procedures to minimize accidents and ensure a safe working environment.

5. Training and Experience While some formadoras may enter the field with a general education in manufacturing or engineering, many acquire specialized training through vocational schools or apprenticeships, gaining hands-on experience that complements their technical knowledge.

formadora perfil metalcon canal

Responsibilities of a Formadora

The responsibilities of a formadora extend beyond mere fabrication. They play a crucial role in various stages of production, including

- Design Interpretation Formadoras are often called upon to interpret blueprints and technical drawings, ensuring that their work aligns with the intended design specifications. - Quality Control Throughout the forming process, they must monitor the quality of the materials and finished products, conducting tests and inspections to uphold standards.

- Collaboration Working closely with engineers, designers, and other technicians is essential for aligning production goals. Effective communication helps maintain workflow and resolves any issues that may arise.

- Maintenance Regular maintenance and troubleshooting of machinery are part of a formadora's responsibilities, ensuring equipment runs smoothly and efficiently.

Importance in the Metalcon Industry

The contribution of formadoras to the Metalcon industry is invaluable. Their expertise directly impacts the quality and efficiency of production processes. With the industrial sector increasingly focusing on sustainability, formadoras also play a vital role in implementing eco-friendly practices. By optimizing manufacturing techniques and reducing waste, they help the industry meet contemporary environmental standards.

Moreover, as technology continues to advance, formadoras are encouraged to update their skills and knowledge regularly. This commitment to continuous education ensures that they remain competitive within the industry and can leverage new technologies such as automation and artificial intelligence in their workflows.

Conclusion

The role of a formadora in the Metalcon industry is multifaceted and essential for the creation of high-quality metal components. Their unique skill set, focused on technical proficiency and a keen eye for detail, not only propels production processes but also guarantees adherence to safety and quality standards. As the industry progresses, the demand for skilled formadoras will continue to grow, presenting opportunities for innovation and advancement in this dynamic field. Embracing the evolving nature of their profession, formadoras are set to remain pivotal in shaping the future of the Metalcon industry.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025