Advanced Flying Shear Roll Forming Machine Suppliers for Precision Metal Fabrication

Flying Shear Roll Forming Machine A Comprehensive Overview for Manufacturers

In the realm of manufacturing, efficiency and precision are paramount, especially in processes involving steel and other metal products. Among the innovative solutions employed by industry leaders is the flying shear roll forming machine. This sophisticated piece of equipment plays a crucial role in enhancing productivity, particularly in the production of continuous profiles that require quick, seamless cutting operations.

What is a Flying Shear Roll Forming Machine?

A flying shear roll forming machine is an advanced type of machinery designed to cut metal profiles at high speeds while they are in motion. This process integrates the rolling and cutting phases, allowing for a continuous production flow without interrupting the manufacturing cycle. The machine ensures that materials are processed quickly, which minimizes downtime and maximizes output. It is especially useful in applications where materials must be cut into specific lengths while maintaining a high level of consistency and quality.

The Mechanism Behind It

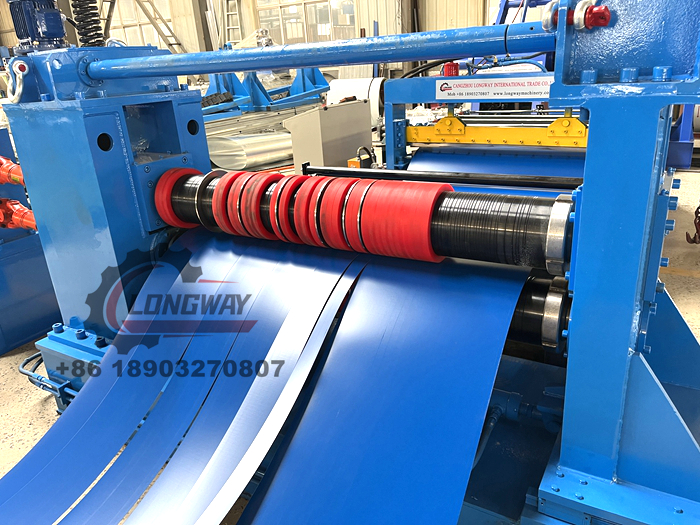

The flying shear process typically involves a series of rotating blades that operate in synchronization with the speed of the moving material. As the metal profile passes through the machine, the blades cut it to the required length while it continues to advance. This not only enhances efficiency but also reduces the risk of defects that can occur when materials are stopped for cutting. The precision of the cut is critical and is achieved through carefully engineered controls that account for the speed and position of the metal as it moves through the machine.

Applications in Various Industries

Flying shear roll forming machines are vital in a range of industries, including construction, automotive, and appliances. They are commonly used to produce steel framing, roofing sheets, and various structural components. In the automotive industry, these machines contribute to the manufacture of chassis and body parts that require high precision and rapid production capabilities.

flying-shear roll forming machine manufacturer

Moreover, the ability to produce complex shapes and profiles without extensive retooling makes flying shear machines highly versatile, catering to diverse product lines and specifications. Manufacturers can quickly switch between different profiles, allowing them to adapt to changing market demands without significant investment in new machinery.

Advantages of Flying Shear Roll Forming Machines

1. Increased Efficiency By combining the cutting and forming processes, manufacturers can significantly reduce cycle times and increase throughput. 2. Minimized Waste The precision of the flying shear process leads to reduced scrap material, which translates to cost savings and more sustainable manufacturing practices.

3. High-Quality Outputs The continuous nature of the process ensures that the finished profiles maintain consistent dimensions and superior surface quality, essential for meeting stringent industry standards.

4. Flexibility These machines can handle various materials, including different grades of steel and alloys, making them adaptable for numerous applications.

Conclusion

As the industry evolves and the demand for high-quality, efficient manufacturing processes intensifies, flying shear roll forming machines stand out as a transformative solution for manufacturers. By embracing this technology, companies can enhance their production capabilities, reduce costs, and maintain a competitive edge in the ever-evolving marketplace. Investing in advanced machinery like the flying shear roll forming machine is not just a step towards modernization; it is a strategic move towards achieving long-term operational excellence.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025