floor deck roll forming machine suppliers

The Rise of Floor Deck Roll Forming Machine Suppliers

In the ever-evolving landscape of the construction industry, efficiency and quality are paramount. One of the key tools facilitating these principles is the floor deck roll forming machine. These machines are essential for manufacturers who produce floor deck panels used in various construction applications, including commercial buildings, warehouses, and residential structures. The demand for such equipment has led to a surge in suppliers specializing in floor deck roll forming machines, each vying for a competitive edge in the marketplace.

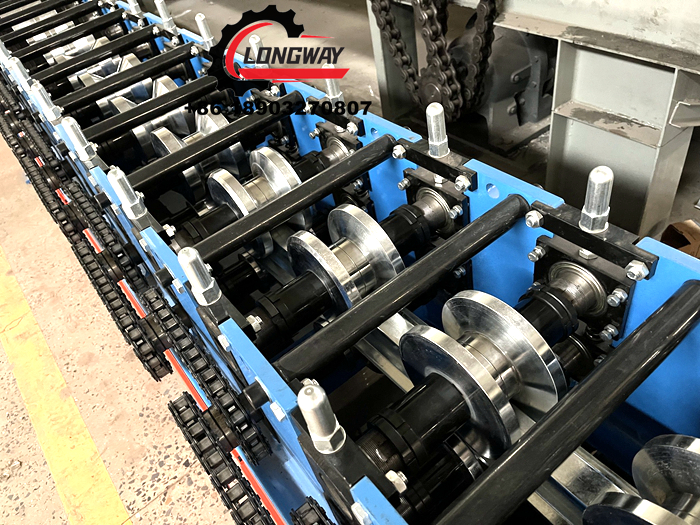

Understanding Floor Deck Roll Forming Machines

Floor deck roll forming machines are designed to manufacture floor decking materials by continuously forming metal sheets into specified profiles. This process typically involves feeding a coil of metal into the machine, which then shapes it through a series of rollers. The end product is robust floor deck panels that not only provide structural support but also enhance the speed of construction projects. These machines are praised for their efficiency, allowing manufacturers to produce large volumes of high-quality panels with minimal waste.

The Market Landscape

The increased demand for sustainable and efficient construction solutions has propelled the growth of the floor deck roll forming machine market. Suppliers are now focusing on advanced technologies that enhance automation, precision, and speed in production. Among the key trends, the integration of smart technologies and Industry 4.0 principles stands out. Suppliers are harnessing the power of artificial intelligence, machine learning, and IoT (Internet of Things) to optimize production processes and enhance product quality.

Key Suppliers in the Industry

floor deck roll forming machine suppliers

Several prominent suppliers have emerged as leaders in the floor deck roll forming machine market. These suppliers not only provide machines but also support their clients with technical expertise and after-sales services. Companies like Tuhorse, JMT, and Metform are known for their innovative designs and robust machines that cater to various needs. They focus on creating customizable solutions, allowing clients to tailor the machinery to their specific production requirements. This flexibility is critical for companies aiming to adapt to diverse construction demands.

Benefits of Engaging with Reputable Suppliers

Partnering with reputable floor deck roll forming machine suppliers brings numerous advantages. First and foremost, these suppliers often have extensive experience in the industry, which translates into superior product knowledge and support. They can provide valuable insights into machine maintenance, production efficiency, and troubleshooting, ensuring a seamless operational process.

Moreover, reliable suppliers generally offer warranties and after-sales support, which safeguard manufacturers against unforeseen challenges. In an industry where time is money, having access to prompt service and expert advice can significantly reduce downtime and enhance productivity.

Conclusion

The role of floor deck roll forming machine suppliers is becoming increasingly crucial as the construction industry continues to evolve. With advancements in technology and a growing emphasis on efficiency and sustainability, these suppliers are at the forefront of an important movement. By ensuring the availability of high-quality, innovative machinery, they facilitate improved construction processes that benefit clients and builders alike. As we move forward, it will be fascinating to see how these suppliers adapt to changing market demands and technological advancements, further shaping the construction landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025