Floor Deck Forming Equipment Producers and Suppliers in the Industry

The Rise of Floor Deck Forming Machine Manufacturers

In the ever-evolving landscape of construction technology, floor deck forming machines have emerged as pivotal tools in the production of composite floor systems. The demand for these machines has surged in recent years due to the increasing need for efficient and cost-effective construction solutions. As a result, numerous manufacturers are stepping onto the scene, each contributing to a rich tapestry of innovation and specialization in this niche industry.

Understanding Floor Deck Forming Machines

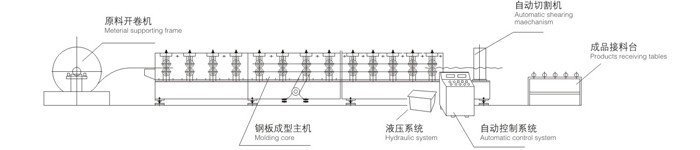

Floor deck forming machines are engineered to produce concrete floor decks, which are integral components in modern multi-story buildings, warehouses, and industrial facilities. These machines are designed to form, cut, and shape metal decking, creating a durable and reliable structure that supports concrete floors during the pouring process. The primary materials used in the manufacturing of floor decks are typically steel or galvanized metal, which provide strength and stability.

These machines vary widely in design and capability, ranging from smaller units suitable for low-volume production to larger, highly automated systems capable of high-output operations

. As construction projects become larger and more complex, the demand for advanced forming machines that can handle diverse specifications and rapid production has skyrocketed.Key Manufacturers and Innovations

The market is populated by a plethora of manufacturers specializing in floor deck forming machines. Notable players include global giants like AWEA Mechantronic Co., Ltd., Pittsburgh Machine Tool, and RoboDeck Technologies. These companies have invested heavily in research and development to stay ahead of the curve, striving to deliver machines that are not only high-performance but also energy-efficient and environmentally friendly.

Innovations in technology have also transformed the capabilities of floor deck forming machines. Modern machines now incorporate advanced features such as automatic material feeding systems, computer numerical control (CNC) programming for precise production, and real-time monitoring systems that ensure quality control at every stage of the manufacturing process. Such advancements enable manufacturers to meet the stringent quality standards and fast-paced demands of the construction industry.

floor deck forming machine factory manufacturers

Environmental Considerations

In today's market, sustainability is a significant focus. Manufacturers are increasingly adopting eco-friendly practices, such as utilizing recycled materials in their machines and implementing energy-efficient manufacturing processes. This trend is not merely a response to regulatory requirements but reflects a broader commitment to corporate social responsibility within the industry.

Among manufacturers, there is a growing emphasis on producing machines that can minimize waste during the forming process. Technologies such as laser cutting and advanced forming techniques contribute to achieving higher material utilization rates. These efforts are critical as the construction industry faces heightened scrutiny regarding its environmental impact, prompting manufacturers to innovate toward greener operations.

Challenges and Opportunities

Despite the promising growth of the floor deck forming machine market, manufacturers face several challenges, including fluctuating raw material prices and increasing competition from lower-cost regions. Moreover, the ongoing global supply chain disruptions have affected the availability of essential components, leading to delays in production.

However, these challenges also present opportunities for manufacturers to differentiate themselves through innovation, superior customer service, and enhanced product offerings. By focusing on customization and flexibility, manufacturers can cater to the unique requirements of different construction projects.

Conclusion

As the construction industry continues to adapt to modern demands, floor deck forming machine manufacturers play an essential role in shaping the future of building methods. The rise of innovative technologies and a commitment to sustainability will pave the way for unparalleled advancements in this sector. Companies that embrace these changes and focus on providing high-quality, efficient solutions will undoubtedly lead the market. Ultimately, the evolution of floor deck forming machines signifies a transformative period in construction, promising enhanced productivity and sustainability for years to come.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025