Fencing Panel Production Machinery Supplier and Manufacturer

The Role of Fence Panel Machine Manufacturers in Modern Fencing Solutions

In today’s fast-paced world, the demand for efficient and high-quality fencing solutions has surged significantly. As properties become more diverse and the need for security, aesthetics, and privacy grows, the role of fence panel machine manufacturers has become increasingly crucial. These manufacturers provide advanced machinery that helps in the mass production of various types of fence panels, catering to the diverse needs of both residential and commercial clients.

Understanding Fence Panel Machines

Fence panel machines are specialized equipment designed to automate the manufacturing process of fence panels. They typically include features for cutting, assembling, and sometimes treating wood or metal materials that are used in fence construction. The machines can vary significantly in complexity, ranging from simple manual-operated tools to sophisticated fully automated systems. The evolution of technology in this industry has led to machines that are not only faster and more efficient but also capable of producing panels with intricate designs and superior quality.

The Benefits of Automated Production

One of the primary advantages of using fence panel machines is increased efficiency. Automated systems can produce large quantities of panels in a fraction of the time it would take to create them manually. This efficiency is vital for manufacturers looking to meet growing demand without compromising on quality. Moreover, automated processes reduce labor costs and minimize human error, ensuring that each panel produced meets the specified standards.

Another benefit is the consistency in quality. Modern fence panel machines are designed to adhere to strict manufacturing guidelines, which results in uniform products with identical dimensions and finishes. This consistency is crucial for projects that require large numbers of panels, such as commercial fencing for properties like warehouses, schools, or parks.

Customization and Versatility

Today’s fence panel machines are not only efficient but also highly versatile. They can be configured to produce a wide range of panel types, including wooden panels, vinyl panels, and even metal fencing solutions. Manufacturers can easily switch between different materials and designs, allowing businesses to cater to specific customer needs or market trends. This flexibility is a significant advantage in an industry where consumer preferences can shift rapidly.

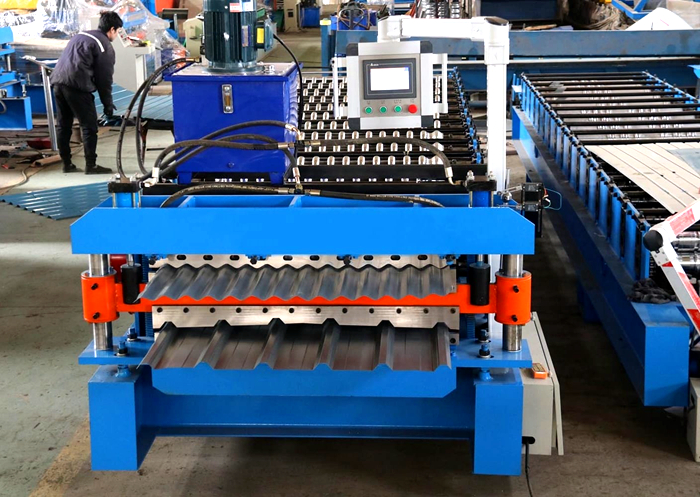

fence panel machine manufacturer

Furthermore, many manufacturers now offer customization options that allow clients to create unique designs. Whether it’s adding decorative elements or producing panels in various colors and textures, the machinery can accommodate a diverse array of specifications. This ability to customize panels enhances the aesthetic appeal of fences and provides clients with products that align closely with their vision.

Sustainability in Fencing Manufacturing

As global awareness around sustainability increases, fence panel machine manufacturers have started to incorporate eco-friendly practices into their production processes. This includes utilizing sustainable materials, such as reclaimed wood, and implementing energy-efficient practices. Many machines are designed to minimize waste, using advanced cutting technologies that ensure the maximum amount of product is obtained from each raw material piece. By adopting these practices, manufacturers can contribute to environmental sustainability, making their products more appealing to eco-conscious consumers.

The Future of Fence Panel Manufacturing

The future of fence panel machine manufacturing looks promising, driven by advancements in technology and increasing consumer expectations. Innovations such as Artificial Intelligence (AI) and the Internet of Things (IoT) are beginning to reshape manufacturing processes, allowing for smarter and more efficient production lines. Manufacturers are increasingly adopting these technologies to improve operational efficiency, monitor machinery health, and predict maintenance needs.

Moreover, as market demands evolve, manufacturers are likely to explore new materials, such as composite materials that offer durability with reduced maintenance requirements. This challenge presents an opportunity for machine manufacturers to innovate further and create solutions that meet the changing landscape of fencing needs.

Conclusion

In conclusion, fence panel machine manufacturers play an integral role in the modern fencing industry. With their ability to produce high-quality, customizable, and eco-friendly products efficiently, they cater to a growing market that seeks both functionality and aesthetics. As technology continues to advance, these manufacturers will be at the forefront of shaping the future of fencing, ensuring that they meet the needs of a dynamic marketplace while contributing to sustainability efforts. Their innovations not only enhance the industry but also provide consumers with a plethora of fencing options that can help transform spaces into beautiful, secure environments.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025