Fascia Roll Forming Equipment Producer for Efficient and Durable Construction Solutions

Fascia Roll Forming Machine Manufacturers An Overview

In the modern manufacturing landscape, fascia roll forming machines play a crucial role in producing high-quality fascia boards used in construction and architectural design. These machines are essential for transforming raw metal materials into precision-engineered products that not only provide aesthetic appeal but also ensure durability and functionality in various applications. As the demand for customizable architectural features increases, the role of fascia roll forming machine manufacturers becomes increasingly significant.

Fascia roll forming machines are designed to perform a series of processes to create specific profiles from metal coils. The journey begins with the feeding of raw materials, often galvanized steel or aluminum, into the machine. These materials are then roll-formed into the desired shape using a series of rollers. After the shaping process, machinery may include additional features such as cutting systems, punching tools, and bending capabilities to ensure that the final product meets precise specifications.

Manufacturers of fascia roll forming machines are responsible for developing equipment that is not only efficient but also reliable and easy to operate. Advanced technology plays a pivotal role in this process. Many manufacturers incorporate automated systems and Computer Numerical Control (CNC) technology to enhance precision and reduce production times. This technological integration allows for greater flexibility in design, enabling manufacturers to produce varying lengths and shapes according to customer needs.

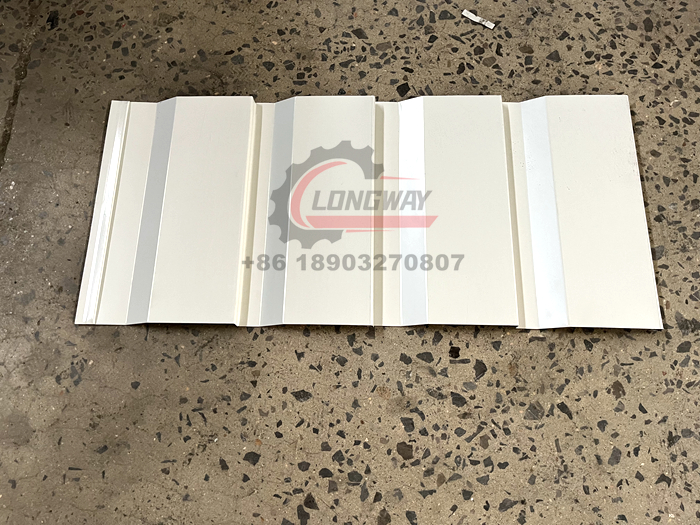

fascia roll forming machine manufacturer

When selecting a fascia roll forming machine manufacturer, several key factors must be considered. Quality assurance is paramount; prospective buyers should look for manufacturers that adhere to industry standards and utilize high-grade materials in their machinery. Additionally, technical support and after-sales services are crucial in ensuring that companies can maintain their equipment efficiently and effectively.

Another important consideration is innovation. The best manufacturers consistently invest in research and development to improve their machines and adapt to changing market trends. This commitment to innovation helps manufacturers stay ahead of the curve, providing customers with cutting-edge solutions that meet evolving demands.

In conclusion, fascia roll forming machine manufacturers are integral to the construction and architectural sectors, supplying essential machinery that enables the production of high-quality fascia boards. The combination of advanced technology, quality assurance, and a commitment to customer service sets the leading manufacturers apart. As the industry continues to evolve, these manufacturers will remain pivotal in shaping the future of structural design and building aesthetics, ensuring that both functionality and style are achieved in every project.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025