Fascia Roll Forming Equipment Manufacturer for High-Quality Custom Solutions

The Evolution and Benefits of Fascia Roll Forming Machines

In the realm of modern manufacturing, efficiency and precision are paramount. The fascia roll forming machine has emerged as a pivotal technology, streamlining the production of fascia boards that are essential in construction and design. This article explores the significance, evolution, and benefits of fascia roll forming machines and the companies that specialize in this innovative machinery.

Understanding Fascia Roll Forming Machines

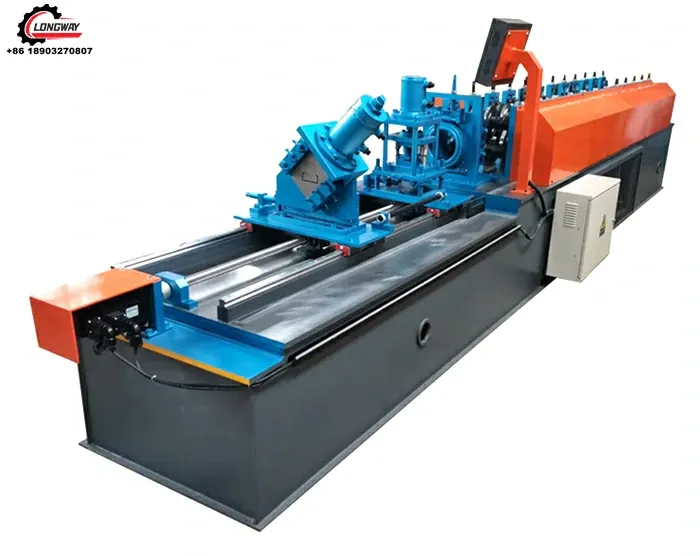

Fascia roll forming machines are specialized equipment designed to create fascia boards from metal sheets. These boards are typically used in the construction of buildings, where they serve as a finishing touch that enhances aesthetic appeal while providing essential protection to underlying structures. The machines work by feeding metal strips into a series of rollers that shape and form the material into the desired profile without producing waste. This process ensures that each piece is consistent, highly reliable, and custom-made to meet specific architectural designs.

Historical Context

The introduction of roll forming technology dates back to the early 20th century, but it wasn't until the late 20th and early 21st centuries that advanced innovations began to define the fascia roll forming machine market. Initially, these machines were manually operated, limiting their efficiency and output. However, with the advent of automation and computer numerical control (CNC), fascia roll forming machines have evolved into sophisticated systems capable of producing a wide variety of profiles with minimal human intervention.

As a result, companies focused on manufacturing these machines began to proliferate, each striving to enhance their offerings with technology that improves speed, accuracy, and ease of use. This evolution has enabled manufacturers to optimize production lines and meet the ever-growing demand for customized building materials.

Key Benefits of Fascia Roll Forming Machines

1. Efficiency and Speed Fascia roll forming machines can produce fascia boards rapidly, significantly reducing lead times for construction projects. The automated processes involved mean that companies can manufacture large quantities in short periods.

2. Cost-Effectiveness Despite the initial investment in machinery, the long-term savings are substantial. The efficiency of roll forming reduces labor costs, minimizes waste, and ensures that energy consumption is lower than traditional manufacturing methods.

fascia roll forming machine company

3. Customization One of the standout features of modern fascia roll forming machines is their ability to create customized profiles tailored to specific architectural needs. This level of customization provides designers and architects with the flexibility to implement unique designs that stand out in the market.

4. Material Versatility These machines can work with a variety of materials, including different grades of metals, which expands the scope of applications. From aluminum and steel to galvanized metals, manufacturers can choose materials that best suit the environmental demands of specific projects.

5. Durability and Strength Fascia boards produced via roll forming are generally stronger and more durable than those made through other fabrication methods. This durability is especially critical in regions facing harsh climate conditions, where protection against environmental elements is essential.

6. Improved Quality Control The precision offered by CNC-controlled fascia roll forming machines ensures that every product produced meets strict quality standards. This consistency minimizes defects and enhances the overall value of the final product.

Choosing the Right Company

When selecting a fascia roll forming machine company, potential buyers should consider several factors. First, assess the company’s reputation in the industry; reading testimonials and understanding their track record can provide insights into their reliability. Furthermore, examine the level of customer support and after-sales service they offer, as this can significantly impact the long-term usability of the machinery.

Secondly, understanding the company's technology and innovation capabilities is critical. The most advanced companies harness cutting-edge technology to improve their machinery's efficiency and capabilities continually. Finally, focusing on machines that offer training and support ensures users can maximize the benefits of their investment.

Conclusion

Fascia roll forming machines are a testament to how technology is reshaping the manufacturing landscape. By providing a blend of efficiency, customization, and durability, these machines have become indispensable for companies looking to elevate their production capabilities in the construction industry. As the demand for high-quality materials continues to rise, the role of fascia roll forming machine companies will remain critical to meeting the needs of builders and architects worldwide. Embracing this technology can lead to a more responsive, sustainable, and innovative construction sector.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025