Advanced Roll Forming Machine for False Ceiling Production and Customization Solutions

The False Ceiling Roll Forming Machine A Game-Changer in Construction Technology

In the world of modern architecture and interior design, the need for efficient production processes has never been more paramount. One remarkable innovation that has emerged is the false ceiling roll forming machine. This advanced equipment not only revolutionizes the way ceilings are constructed but also enhances the quality and aesthetics of architectural designs.

Understanding False Ceilings

Before delving into the intricacies of the roll forming machine, it’s essential to understand what false ceilings are. A false ceiling, also known as a drop ceiling or suspended ceiling, is an additional layer of ceiling installed below the main one. They serve multiple purposes hiding imperfections, allowing for the installation of lighting fixtures and air conditioning ducts, and enhancing sound insulation. Moreover, false ceilings can be designed using a variety of materials, including gypsum boards, metal, and PVC, making them versatile solutions for various environments, from residential homes to commercial spaces.

The Role of Roll Forming Machines

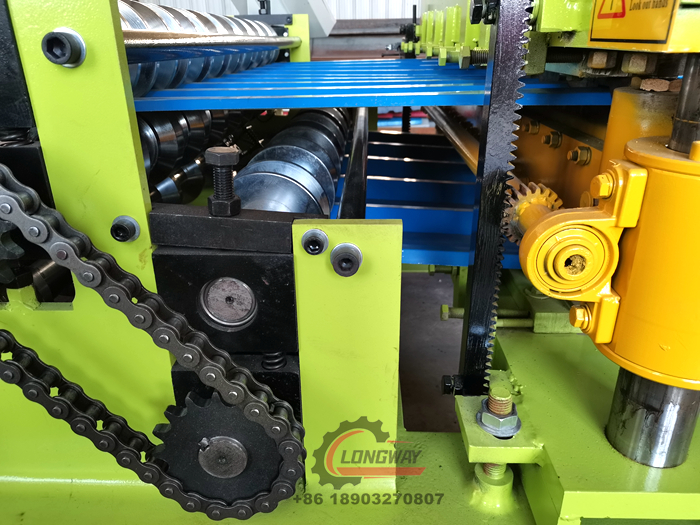

A roll forming machine is a piece of equipment that creates specific shapes and profiles from metal sheets. It employs a continuous bending process where a long strip of metal is passed through a series of rollers to produce the desired cross-section. This technique is particularly beneficial for producing components with consistent quality and precision, which is critical in architectural applications.

With the advancement of technology, false ceiling roll forming machines have become increasingly sophisticated. They are capable of producing intricate designs and profiles that were once labor-intensive and time-consuming to create by hand. The automation and efficiency of these machines significantly reduce production time and costs, making them a game-changer in the construction industry.

Advantages of Using a False Ceiling Roll Forming Machine

1. Efficiency Traditional methods of constructing false ceilings can be slow and require skilled labor. In contrast, roll forming machines can produce components at a faster rate, allowing for quicker project completion.

false ceiling roll forming machine

2. Quality Consistency is key in construction. With a roll forming machine, each component is manufactured to exact specifications, reducing wastage and ensuring a high-quality final product.

3. Versatility These machines can produce a variety of profiles and shapes, accommodating different design requirements. Whether it’s a simple flat panel or an intricate mold, roll forming machines can adapt to the needs of the project.

4. Cost-Effectiveness By reducing labor costs and increasing production speed, roll forming machines help lower overall project expenses. The durability of the materials typically used also guarantees longevity, further adding value.

5. Integration with Modern Technology Many roll forming machines now come equipped with computerized controls for enhanced precision and ease of use. This integration allows for faster adjustments and real-time monitoring of production.

Applications in Various Industries

False ceiling roll forming machines are used across a multitude of sectors including residential, commercial, and industrial construction. They are ideal for creating suspended ceiling systems in offices, retail spaces, and even industrial warehouses. The decorative possibilities are endless, with designs ranging from minimalist to elaborate.

The use of roll forming technology extends beyond just false ceilings. It can also be adapted for producing metal framing, edge trims, and other construction components, making it a versatile tool in any builder's arsenal.

Conclusion

The false ceiling roll forming machine stands at the forefront of modern construction technology, embodying efficiency and precision. By leveraging this powerful tool, architects and builders can not only meet but exceed the expectations of contemporary design while maintaining cost-effectiveness. As the demand for innovative building solutions continues to rise, the role of roll forming machines in the construction industry will undoubtedly become even more significant, paving the way for the future of architectural excellence.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025