false ceiling channel making machine manufacturers

The Rise of False Ceiling Channel Making Machines A Manufacturer's Perspective

In recent years, the construction and interior design industries have witnessed a significant transformation with the advent of advanced machinery designed to enhance efficiency and precision. Among these innovations, false ceiling channel making machines have gained considerable attention from manufacturers and contractors alike, revitalizing the way ceilings are constructed in residential, commercial, and industrial spaces.

Understanding False Ceilings and Their Components

False ceilings, also known as suspended ceilings, offer an aesthetically pleasing finish while providing functionalities such as sound insulation, thermal regulation, and the concealment of electrical wirings and plumbing. The efficacy of a false ceiling largely hinges on the quality of its components, particularly the channels that support the ceiling tiles. These channels, often made of galvanized iron or aluminum, are crucial for ensuring stability and durability.

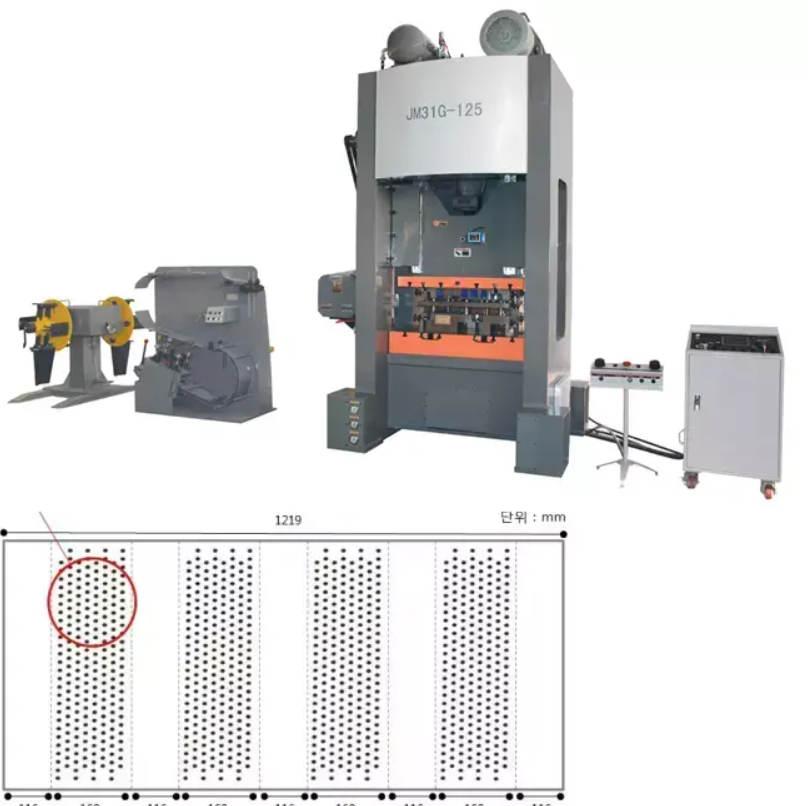

Enter the false ceiling channel making machine, a specialized piece of equipment that fabricates these essential components with precision. By automating the production process, manufacturers are able to produce standardized channels that meet the stringent demands of modern construction projects.

The Market Demand for False Ceiling Channels

The growing demand for false ceilings across the globe has led to a parallel increase in the need for efficient channel production. Market trends indicate a rising inclination towards modular construction, which emphasizes prefabrication and quick installation. Consequently, manufacturers are seeking innovative solutions to keep up with the fast-paced demands of the industry.

Consumers today are more discerning than ever, often looking for materials that not only boast durability and aesthetic appeal but also come with low environmental impact. As a result, sustainable manufacturing practices are increasingly being integrated into the production of false ceiling channel making machines, with manufacturers focusing on energy-efficient processes and recyclable materials.

false ceiling channel making machine manufacturers

Technological Advancements in Channel Production

Modern false ceiling channel making machines are equipped with sophisticated technology that allows for automation and increased efficiency. Features such as computer numerical control (CNC) capabilities, which enable precise cutting and shaping of materials, have revolutionized the way manufacturers operate. These machines can produce channels of varying sizes and shapes to cater to diverse customer needs, all while minimizing waste.

Additionally, advancements in design software allow manufacturers to create custom channel configurations that not only meet specific architectural requirements but also enhance the overall functionality of false ceilings. As technology continues to evolve, so too does the capacity for innovation in channel design and manufacturing.

Selecting the Right Manufacturer

For contractors and builders, choosing a reliable manufacturer of false ceiling channel making machines is crucial. Factors to consider include the machine’s production capacity, ease of use, and after-sales support. It's essential to partner with a manufacturer that not only provides high-quality machinery but also understands the unique needs of the construction industry.

Moreover, manufacturers should seek suppliers who are committed to ongoing research and development, ensuring that they are equipped with the latest technologies and production techniques. A strong partnership can facilitate knowledge sharing and help contractors stay ahead in an increasingly competitive market.

Conclusion

The false ceiling channel making machine has emerged as a pivotal tool for manufacturers in the construction sector, enabling them to meet the burgeoning demand for sophisticated false ceilings. With a strong focus on automation, sustainability, and quality, these machines are redefining the production landscape. As the industry continues to evolve, embracing innovation and efficiency will be key strategies for manufacturers looking to thrive in a dynamic market. The future of false ceilings is promising, and those who adapt will shape the ceilings of tomorrow.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025