false ceiling channel machine factories

False Ceiling Channel Machine Factories Revolutionizing Construction and Interior Design

The construction and interior design industries are continuously evolving, driven by advancements in technology and the demand for innovative building materials. Among these innovations, false ceilings have gained significant popularity due to their versatility, aesthetic appeal, and functional advantages. At the heart of this trend are false ceiling channel machine factories, which play a crucial role in manufacturing the components needed for modern false ceiling systems.

Understanding False Ceilings

False ceilings, also known as drop ceilings or suspended ceilings, are secondary ceilings that are hung below the main structural ceiling. They serve multiple purposes, including enhancing the aesthetic appearance of interiors, improving acoustics, concealing wiring and plumbing, and providing thermal insulation. With an increasing focus on creating comfortable and visually appealing spaces in commercial and residential properties, the demand for high-quality false ceiling systems has surged.

The Role of Channel Machines

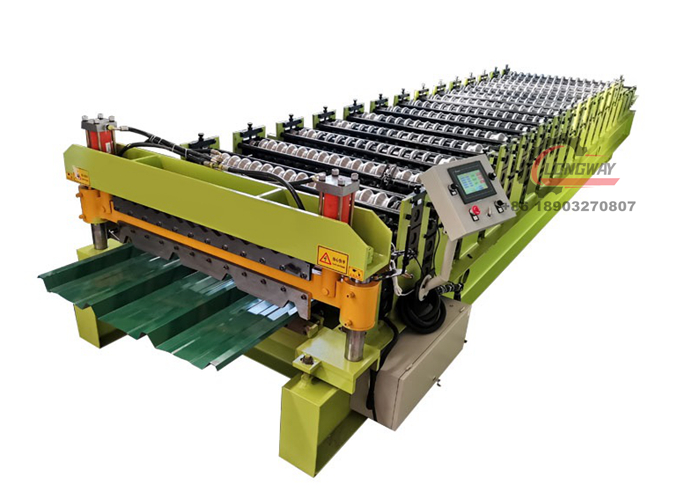

False ceiling channel machines are essential tools in the manufacturing process of false ceilings. These machines are designed to produce various components, including metal channels, grid systems, and support structures. The precision and efficiency of these machines ensure that manufacturers can produce high-quality components that meet industry standards and client specifications.

Factory production of these components is streamlined and often involves automated processes that reduce labor costs and improve output speed. Modern channel machines are equipped with advanced technology, including computer numerical control (CNC), which allows for precise cutting, bending, and shaping of materials. This technological advancement ensures consistency and accuracy, which are paramount in the construction industry.

The Manufacturing Process

false ceiling channel machine factories

In a typical false ceiling channel machine factory, the manufacturing process begins with the selection of raw materials, commonly steel or aluminum, due to their durability and lightweight properties. The materials are fed into the channel machines, where they undergo various operations such as cutting, punching, and shaping.

Once the initial components are produced, they are subjected to quality checks to ensure they meet the required standards. This quality assurance process is critical, as any flaws in the components can lead to structural issues when installed as part of a false ceiling system. After passing quality control, the components are finished and prepared for packaging and distribution.

Market Trends and Innovations

As the demand for false ceilings continues to rise, so too does the innovation within false ceiling channel machine factories. Manufacturers are investing in research and development to create more efficient machines, which can produce components faster and at a lower cost. Additionally, there is a growing trend toward sustainable manufacturing practices, with factories looking to minimize waste and use eco-friendly materials whenever possible.

Automation has also become a key focus for many factories. Automated channel machines can operate continuously, drastically increasing production rates while reducing the need for manual labor. This not only enhances productivity but also allows factories to adapt more quickly to changing market demands.

Conclusion

False ceiling channel machine factories are at the forefront of a significant shift in the construction and interior design industries. By providing essential machinery for the production of high-quality false ceiling components, these factories are enabling the widespread adoption of false ceilings in various applications. As technology continues to advance, the role of these factories will likely become even more critical, paving the way for more innovative and efficient building practices. In an era where aesthetics and functionality are paramount, the contributions of false ceiling channel machine factories will undoubtedly shape the future of modern architecture and design.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025