Factories Specializing in Portable Metal Roof Roll Forming Machines for Efficient Construction Solutions

Portable Metal Roof Roll Forming Machine Factories

In recent years, the construction industry has witnessed significant advancements in technology, particularly in the manufacturing of roofing materials. One of the standout innovations is the portable metal roof roll forming machine, which has transformed the way metal roofs are produced and installed. This article explores the importance of portable metal roof roll forming machine factories, their operational mechanics, and their impact on the roofing industry.

What is a Portable Metal Roof Roll Forming Machine?

A portable metal roof roll forming machine is a compact piece of equipment designed to create metal roofing sheets on-site. Unlike traditional manufacturing methods where roofing materials are pre-fabricated in a factory, portable roll forming machines allow contractors to produce roofing profiles directly at the construction site. This on-location production not only enhances efficiency but also reduces material waste and transportation costs associated with long-distance deliveries.

The Functionality of Roll Forming Machines

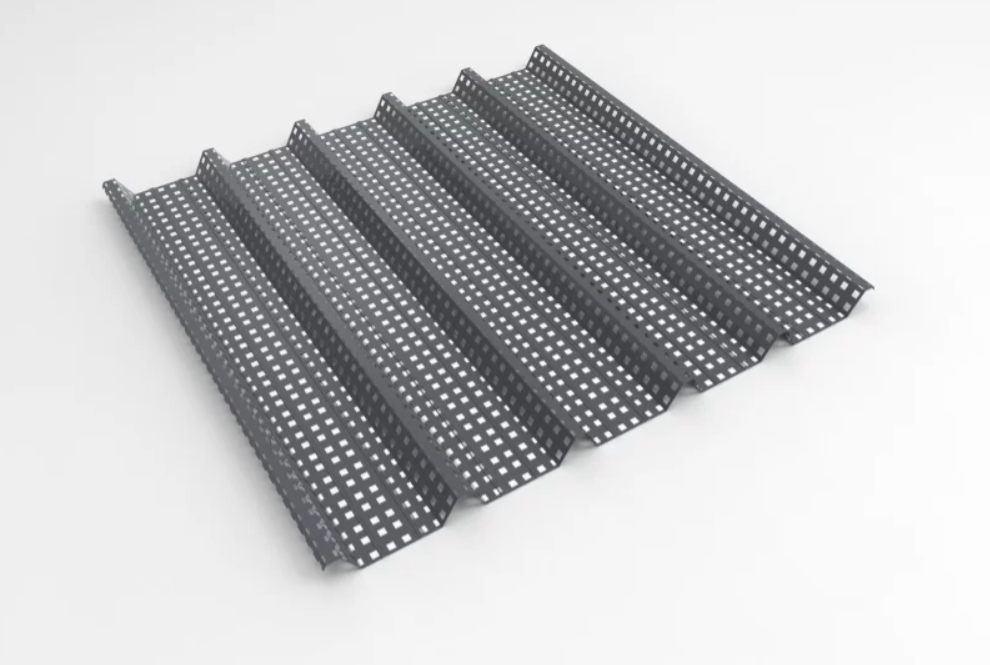

The process begins with metal coils, typically made from galvanized steel or aluminum, which are fed into the machine. As the coils pass through a series of rollers, they are progressively shaped into the desired profile. This process can produce various roofing styles, including standing seam, corrugated, and box rib designs. The flexibility of the machine enables manufacturers to cater to specific client requirements, thereby offering custom solutions for diverse roofing projects.

These machines are engineered with state-of-the-art technology, often featuring digital displays for precise adjustments and control over the forming process. Moreover, portable machines are equipped with hydraulic or electric drives, enabling them to operate effectively on different job sites, regardless of the power source available.

Advantages of Portable Metal Roof Roll Forming Machines

1. Cost Efficiency By producing material on-site, contractors save on transportation fees and can significantly cut down on the costs associated with excess inventory and material waste.

portable metal roof roll forming machine factories

2. Time Savings The ability to form metal sheets on-site expedites the roofing process. Contractors can install roofing materials as they are being produced, allowing for quicker project turnaround times.

3. Customization Clients can request specific profiles and dimensions tailored to their projects. This level of customization ensures that the final product meets precise architectural requirements.

4. Quality Control Manufacturers can maintain higher quality standards since the production process is closely monitored. The on-site production minimizes the likelihood of damage during transport.

5. Portability and Flexibility These machines are designed with mobility in mind, allowing them to be easily transported between various job sites. This flexibility is crucial for contractors who handle multiple projects in differing locations.

The Role of Factories in Advancing Technology

The rise in popularity of portable metal roof roll forming machines has led to an increase in specialized factories dedicated to their production. These factories focus on research and development to enhance machine efficiency, durability, and user-friendliness. As technology evolves, manufacturers integrate advanced features, such as computer numerical control (CNC) systems, to improve precision and automation in the roll forming process.

Moreover, as sustainability becomes a focal point in construction, factories are also innovating to produce machines that use eco-friendly materials and reduce energy consumption during manufacturing.

Conclusion

Portable metal roof roll forming machines have revolutionized the roofing industry, providing unmatched efficiency, cost savings, and customization opportunities. As factories continue to innovate in this field, we can expect further advancements that will enhance the capabilities of these machines. The growth of this technology indicates a bright future for both manufacturers and contractors, paving the way for more streamlined and sustainable roofing solutions.

-

the-role-of-hydraulic-systems-in-sheet-metal-slittersNewsAug.23, 2025

-

customization-options-in-metal-deck-roll-forming-machinesNewsAug.23, 2025

-

safety-tips-when-using-a-gutter-making-machineNewsAug.23, 2025

-

key-components-of-a-c-purlin-machine-explainedNewsAug.23, 2025

-

maintenance-tips-for-a-steel-angle-roll-forming-machineNewsAug.23, 2025

-

portable-metal-roofing-machine-applications-in-remote-constructionNewsAug.23, 2025

-

Roof Panel MachineNewsAug.18, 2025