Exporting High-Quality CZ Purlin Roll Forming Machines for Efficient Construction Solutions

The Rise of CZ Purlin Roll Forming Machine Exporters

In recent years, the construction and manufacturing industries have witnessed a significant shift towards more efficient and cost-effective structural solutions. One of the standout contributors to this transformation is the CZ purlin roll forming machine. This innovative piece of machinery has garnered global attention due to its ability to produce high-quality, lightweight, and durable purlins with precision, paving the way for its rapid proliferation among manufacturers and exporters.

The CZ purlin roll forming machine is designed specifically for the production of C and Z-shaped purlins, which are critical components in building frames, roof support structures, and other applications in the construction sector. The efficiency of this machine lies in its automated roll forming process, which can produce purlins in various sizes and specifications tailored to specific building needs. This versatility has made it a necessary tool for companies looking to stay competitive in a fast-evolving market.

One of the remarkable aspects of CZ purlin roll forming machines is their capacity for mass production without compromising quality. The machines work by feeding flat steel sheets into a series of rollers that gradually shape the material into finished purlins. This continuous process not only speeds up production times but also minimizes material wastage, making it a sustainable choice for manufacturers focused on reducing their environmental footprint.

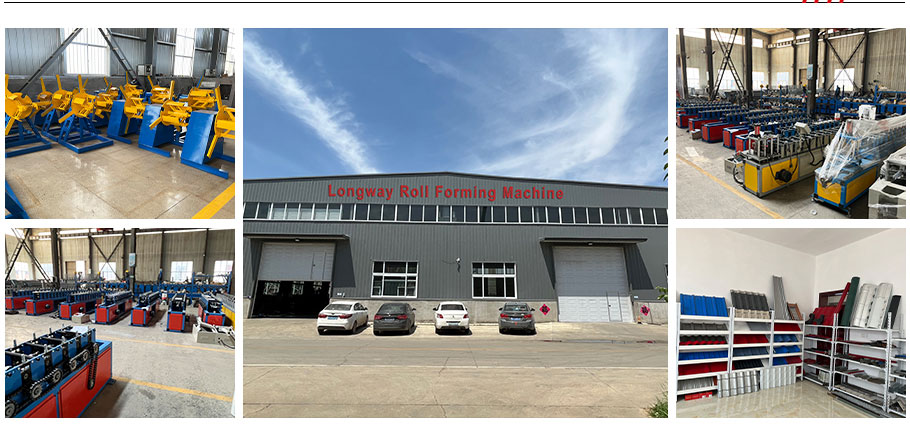

As demand for these machines has surged, a number of exporters have emerged in the international marketplace. These exporters not only supply the machines but also provide additional services including installation, maintenance, and technical support, ensuring that their clients can maximize productivity while maintaining operational excellence. Exporters from countries with robust manufacturing sectors, like China and Germany, have become particularly prominent due to their advanced technologies and cost-effective pricing models.

cz purlin roll forming machine exporter

The emergence of CZ purlin roll forming machine exporters has broadened access to advanced construction technologies worldwide. For construction companies in developing regions, obtaining these machines can significantly enhance their capabilities, enabling them to produce their own purlins locally and thereby reducing dependency on imported materials. This not only lowers costs but also contributes to the growth of local industries.

Furthermore, the export of CZ purlin roll forming machines is indicative of a larger trend in globalization and technological diffusion. Countries that embrace these technologies can spur economic development through the creation of jobs, enhancement of skills, and resilience in the face of competitive pressures. The construction industry benefits immensely from the introduction of innovative machinery, which not only improves the quality of structures but also accelerates projects, leading to shorter completion times.

However, it is essential for buyers to conduct thorough research to select reputable exporters. Quality assurance, warranty conditions, and after-sales support should be key considerations when investing in a CZ purlin roll forming machine. Establishing a strong relationship with a reliable exporter can mean the difference between a successful purchase and costly setbacks.

In conclusion, the export of CZ purlin roll forming machines is transforming the landscape of construction and manufacturing. By providing an efficient, cost-effective solution for producing essential building components, these machines are opening new horizons for businesses worldwide. With continued advancements in technology and manufacturing practices, the future looks promising for CZ purlin roll forming machine exporters and the industries they serve. As these machines become increasingly available, they will undoubtedly play a crucial role in shaping the future of construction across the globe.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025